Marker adjustments, Folding speed, Disk adjustments – Great Plains PT8030 V1013 Operator Manual User Manual

Page 31: Disk angle, Direction of cut, Danger, Warning

29

Section 3 Adjustments

PT6030 and PT8030 Pull-Type Planter 401-032M-A

10/10/12

Great Plains Mfg., Inc.

Marker Adjustments

Folding Speed

!

DANGER!

Never allow anyone near the planter when cycling the markers.

Excessive travel speed of the markers can be dangerous and/or

damage the marker assembly.The flow controls should be prop-

erly adjusted before the marker assembly is first put into use.

!

WARNING!

Escaping fluid under pressure can have sufficient force to pene-

trate the skin. Check all hydraulic lines and houses before ap-

plying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

form a doctor that is familiar with this type of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

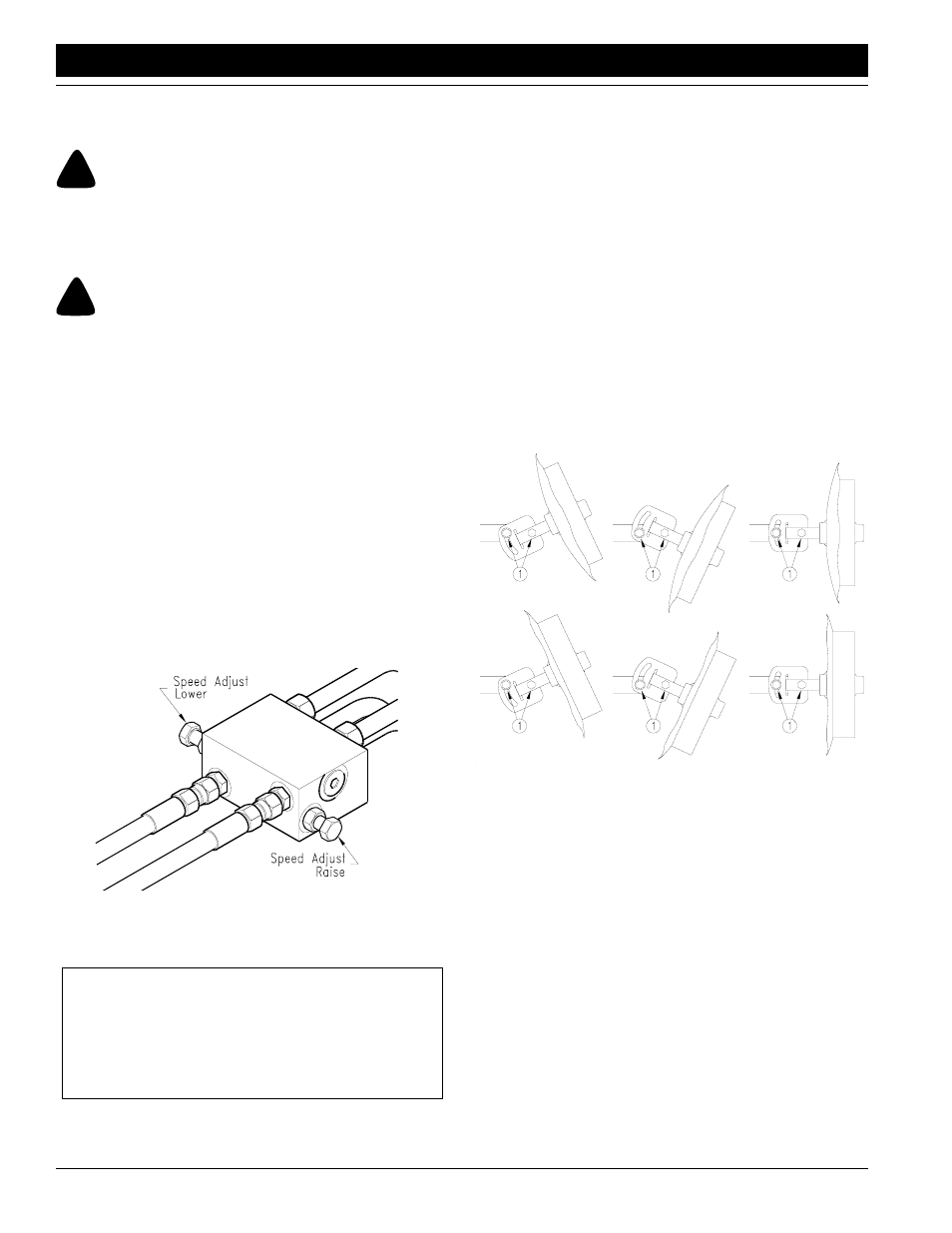

The marker hydraulic system is equipped with needle

valves to control how fast each marker operates. The nee-

dle valves are built into the sequence valve body. There

are two hex adjustment heads, one for controlling marker

speed up and one for controlling marker speed down.

Excessive folding speeds can cause marker damage.

With the tractor engine at an operating rpm, loosen jam

nut and adjust the needle valve to limit the marker to a safe

operating speed. Make sure all adjustments are made

with warm oil. Fold the marker up and down a few times

and recheck for pinching and kinking of hoses.

Figure 3-17

Flow Control Raise/Lower

15029

IMPORTANT: JIC fittings do not require high torque.

JIC and O-Ring fittings do not require sealant. Al-

ways use liquid pipe sealant when adding or replac-

ing pipe thread fittings. To avoid possible danger of

cracking hydraulic fittings from over tightening, do not

use plastic sealant tape.

Disk Adjustments

The aggressiveness and the mark left by the disk may be

changed by two methods.

1.

Disk Angle

To change the angle of cut, loosen the two bolts (1),

rotate the disk assembly and retighten.

2.

Direction of Cut

The disk may be mounted to throw dirt either in or out

which will give different marks in different soil condi-

tions. To change the direction of cut:

a.

Reverse the blade and depth band by remounting

the four lug bolts on the disk hub.

b.

Reverse the angle of the assemble by removing

the adjustment bolts (2) and turning the spindle

assembly one half turn. Re-install and tighten all

bolts.

15834

Figure 3-18

Marker Disk Adjustments