Cds-john blue® ground drive pump, Liquid fertilizer strainer(s), Cds-john blue – Great Plains YP2425A Operator Manual User Manual

Page 67

Great Plains Manufacturing, Inc.

Adjustments

63

2014-02-10

401-626M

CDS-John Blue

®

Ground Drive Pump

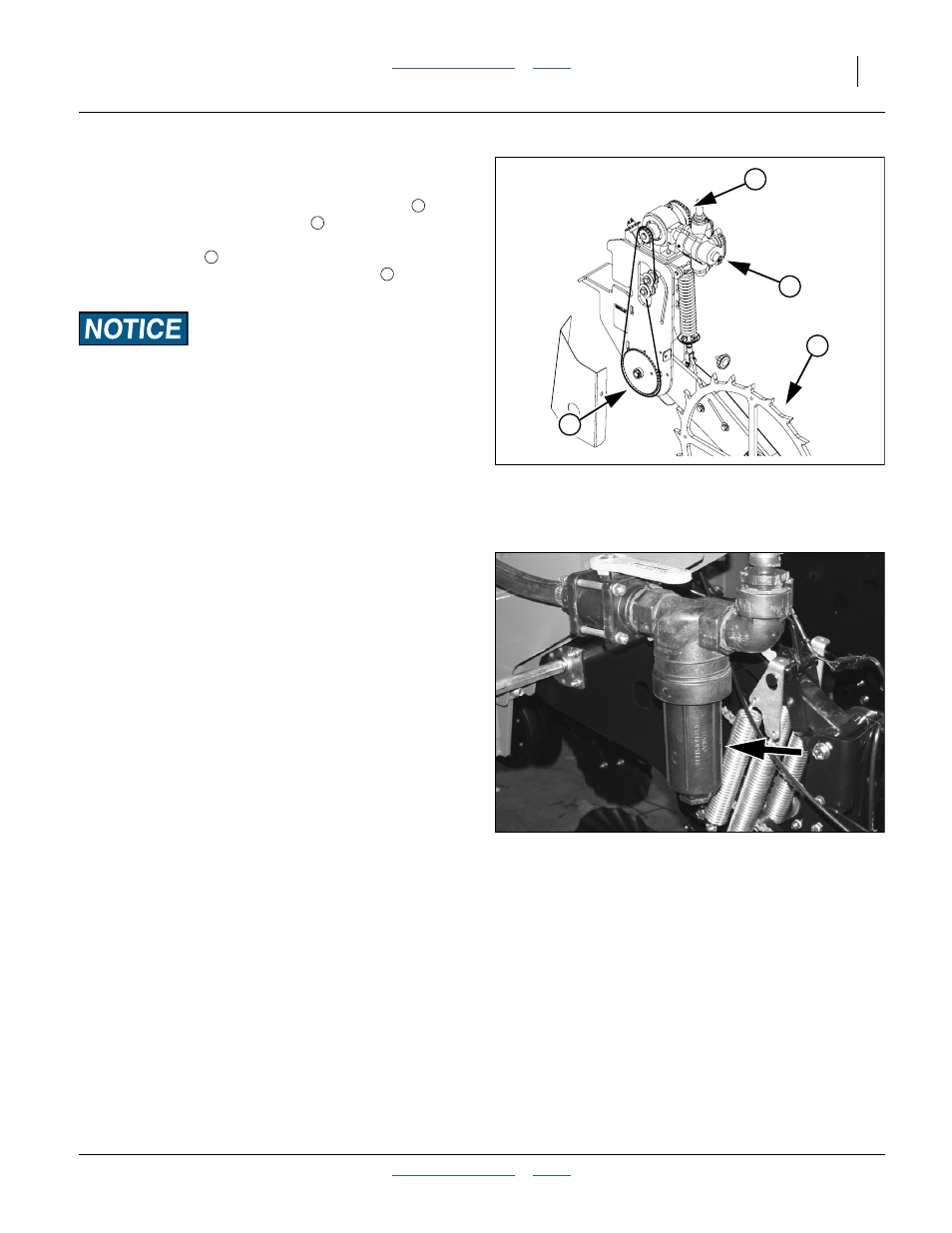

Refer to Figure 73

With newer Type 2 fertilizer systems, the pumps

are

driven by a ground contact wheel

. Fertilizer rate is

independent of seed rate. Fertilizer coarse rate is set by

a driving sprocket

on the ground drive assembly, and

fine rate is adjusted at the setting hub (dial)

on the

pump.

Equipment Damage/Material Loss Risks:

If planting without fertilizing, the pump must not be allowed to

run dry. Disconnect the chain or remove a sprocket. The

ground drive contact wheel and chain system operates

whenever the planter is lowered and in motion.

Note: When a Type 3 fertilizer system is installed, the

pump is mounted at the source (not on the planter),

usually on a tank cart.

For sprocket and dial settings, refer to the Seed Rate

manual.

Liquid Fertilizer Strainer(s)

The optional ground drive fertilizer pump systems

include a strainer at each pump. The Type 3 system

relies on strainers at the source, usually on a tank cart.

The strainer(s) are delivered with a mesh screen. You

need to check that each screen is an appropriate size for

the orifice plates you plan to use.

If changing screen sizes, keep in mind the following:

• Generally, select a mesh screen the same or slightly

smaller than the orifice size.

• A substantially smaller mesh (e.g. 100) will reduce

manifold orifice plates plugging so often, but the

strainer screen will have to be cleaned more often.

• A much larger mesh (e.g. 50 or 30) will pass more

material but should only be considered when using

large manifold orifice plates.

• A plugged or partially plugged screen will starve the

pump and will result in a reduced application rate.

Figure 73

CDS-John Blue

®

Pump

Sprocket and Dial

28416

2

4

3

1

1

2

3

4

Figure 74

Strainer

21965