Marker gauge wheel adjustment, Marker chain length adjustment – Great Plains YP2425A Operator Manual User Manual

Page 59

Great Plains Manufacturing, Inc.

Adjustments

55

2014-02-10

401-626M

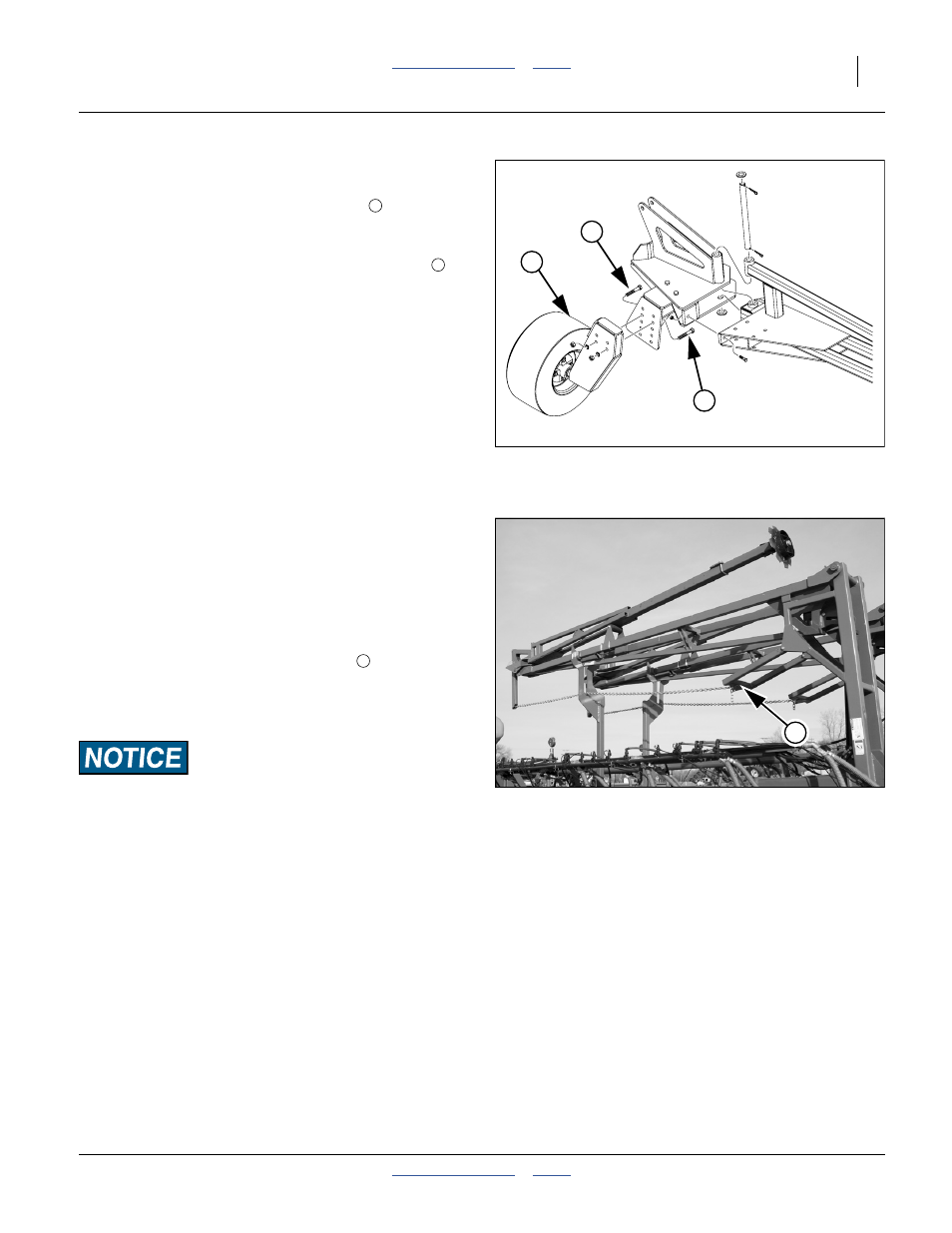

Marker Gauge Wheel Adjustment

Refer to Figure 65

The purpose of the marker support wheel

is to carry

the weight of the inner section of the marker arm.

If the wheel is not touching the ground, or is often off the

ground during marker operations, remove the bolts

and move the wheel to a lower hole.

If the marker disc is frequently off the ground, the

support wheel mount may need to be moved to a higher

set of holes.

Marker Chain Length Adjustment

Great Plains suggests checking marker chain slack

every few years. If any maintenance or repairs cause the

chain to be disconnected, correct slack needs to be set

on reinstallation.

Perform any checks and adjustments with the marker

folded and tilted down into its cradle.

Refer to Figure 66

Lift the free end of the lift arm weldment

until

horizontal. Re-attach chain so that it is taut.

Ideally, the unfolding marker reaches the ground 2-3 feet

(60-90 cm) before the marker is completely unfolded.

Equipment Damage/Marker Failure Risks:

Set correct chain length. A chain length too long can result in

excess loads on the marker and nuisance shears, due to

striking the ground too early during unfolding. An

under-length chain can also prevent the marker from fully

resting in the cradle when folded. A chain too short can result

in unsatisfactory marker operations, including loss of ground

contact on uneven terrain.

Figure 65

Marker Gauge Wheel

29516

2

1

2

1

2

Figure 66

Marker Chain Slack

26057

5

5