Marker maintenance, Marker bleeding, Marker cylinder bleeding – Great Plains YP2425A Operator Manual User Manual

Page 111: Marker shear bolt replacement, Marker grease seal cap

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

107

2014-02-10

401-626M

Marker Maintenance

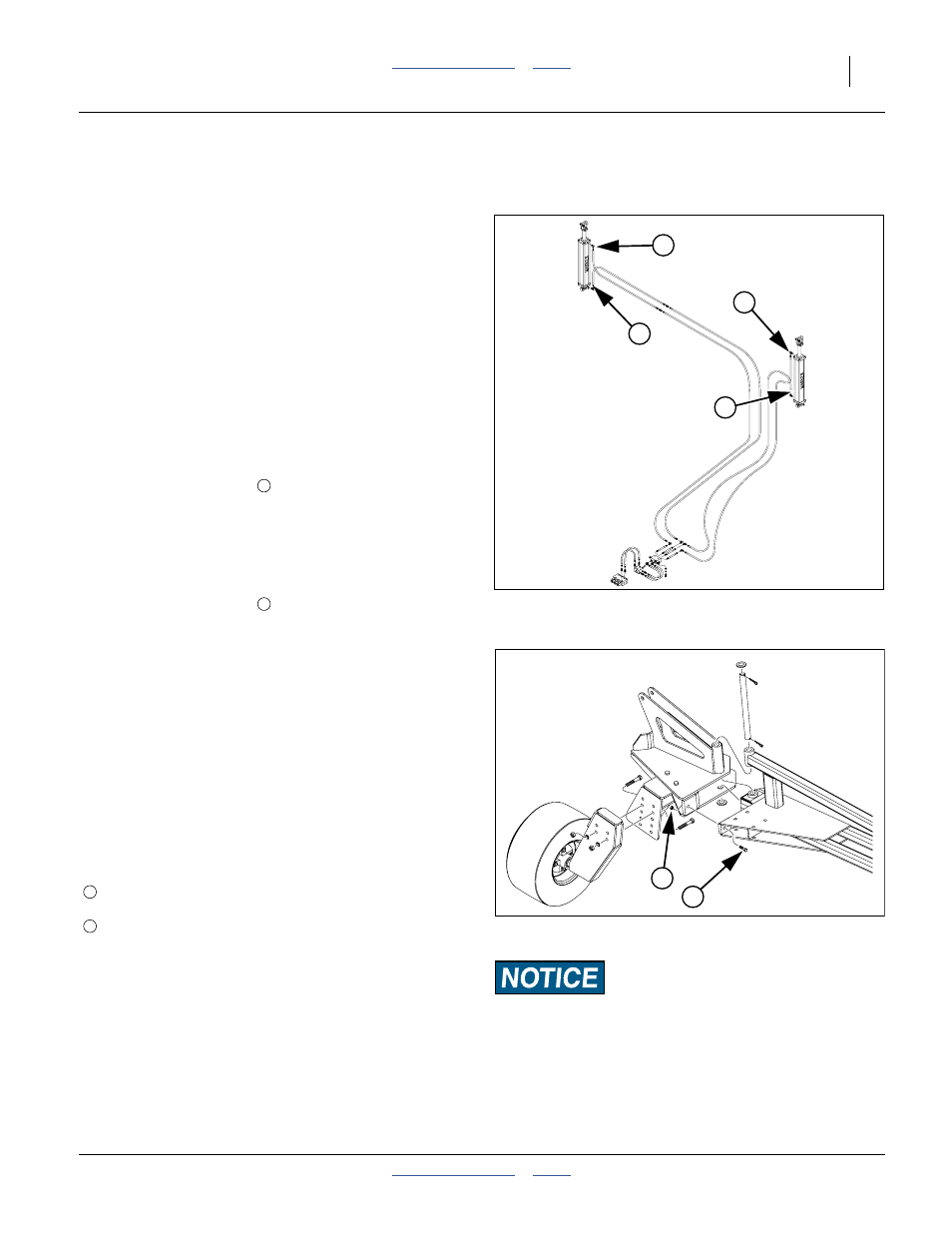

Marker Bleeding

To fold properly, the marker hydraulics must be free of

air. If the markers fold in jerky, uneven motions.

Marker Cylinder Bleeding

Refer to Figure 138

1.

Begin with planter unfolded and lowered, and with

both marker sides extended. See “Unusual Marker

Operations” on page 38.

2.

Note the position of the gravity pin lock (above and

latched on rod-end pin when folded, hanging down

when unfolded).

3.

Un-pin the rod end of the marker cylinders, and

orient the cylinders so that the rods may extend

without striking marker components.

4.

Loosen the JIC fitting

at the base end of one

marker cylinder.

5.

Extend the circuit until fluid appears at the loosened

fittings. It may be necessary to extend-retract-extend

to cycle the sequence valve to that marker. Set

circuit to Neutral. Secure fittings.

6.

Loosen the JIC fitting

at the rod end of that same

marker cylinder.

7.

Retract the circuit until fluid appears at the loosened

fittings. Set circuit to Neutral. Secure fittings.

8.

Repeat for the other side.

9.

Re-orient gravity pin lock to position noted at step 2.

10. Re-pin marker rod ends.

Marker Shear Bolt Replacement

Refer to Figure 139

If a marker gets caught or hits an obstruction, it is

designed to fail a shear bolt at the fold, pivot on a pin,

and swing back.

The shear bolt is a hex head cap screw,

1

⁄

2

-13 x 2

1

⁄

2

inch Grade 5,

Great Plains part number 802-130C, plus a

1

⁄

2

-13 lock nut, Great Plains part number 803-019C.

Install a replacement shear bolt on the vertical faces on

the side opposite from the pivot bolt.

Marker Grease Seal Cap

If grease seal cap for marker-disk-hub bearings is

damaged or missing, disassemble and clean hub.

Repack with grease and install new seal or grease cap.

Figure 138

Marker Bleed

26131

2

1

1

2

1

2

Equipment Damage Risk:

Replacing shear bolt with a higher grade bolt can result in

marker damage. Replacing the shear bolt with a lower grade

can result in nuisance shears.

Figure 139

Marker Shear Bolt

29516

1

2

1

2