Field set-up checklist – Great Plains YP2425A Operator Manual User Manual

Page 50

46

YP2425A

Great Plains Manufacturing, Inc.

401-626M

2014-02-10

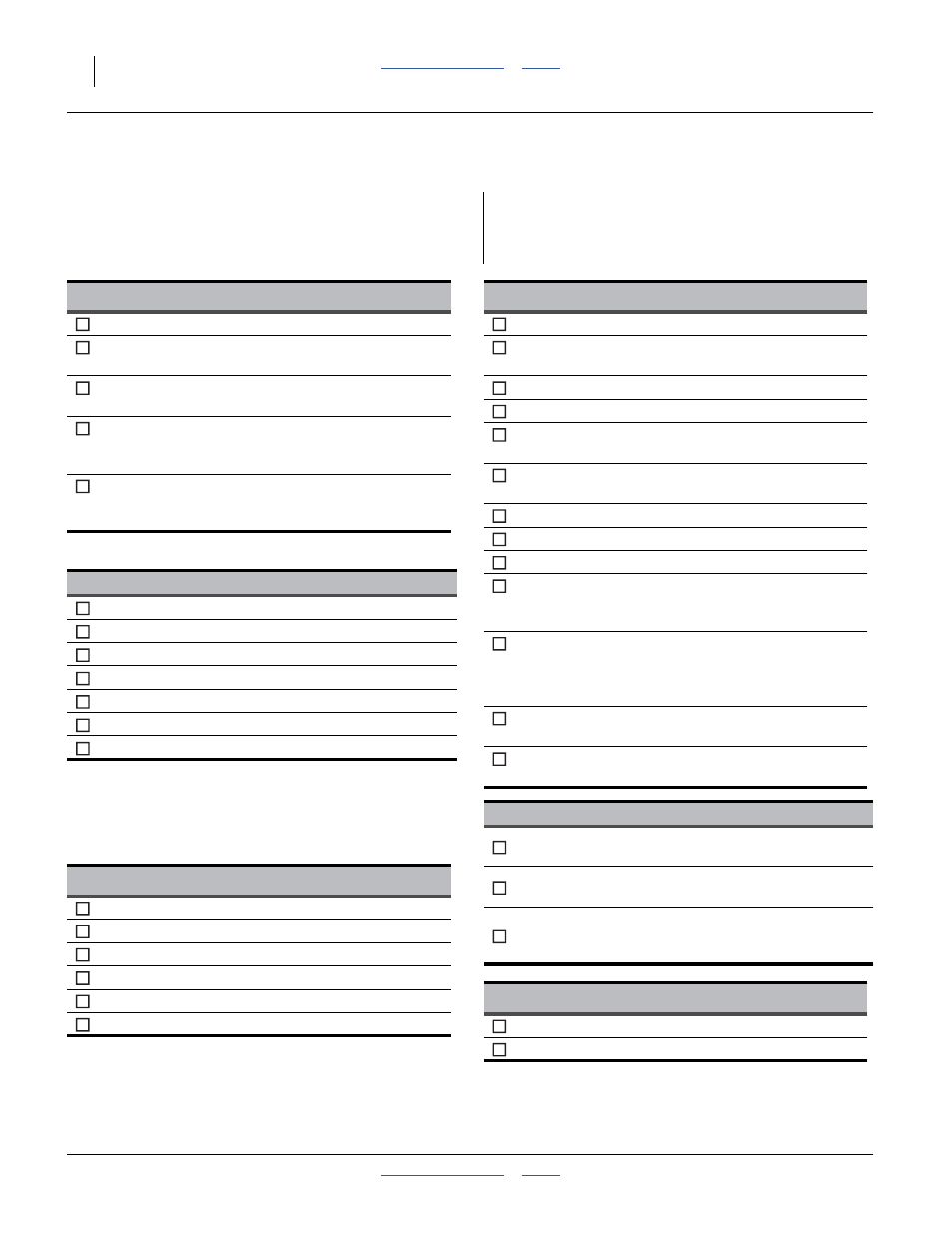

Field Set-Up Checklist

Use the following tables to develop a final checklist for

your tractor/planter configuration. Additional or fewer

steps may be necessary depending on tractor features,

planter options and planting accessories.

To complete checklists, you may need to refer to the:

SRM: Seed Rate Manual (SRM),

PDC: DICKEY-john

®

Planter/Drill Control manuals, or

QSG: DICKEY-john

®

Quick Start Guide

Electrical Checklist

Page

Verify electrical hookups solid

Power-up seed monitor terminal and

observe any diagnostic messages

PDC

Verify Material and Rate, and hydraulic

drive and “SPLIT AIR” Channel setup

QSG

PDC

With hydraulic circuits in neutral, check

switches and indicator lights on CFM

switch panel. Confirm Master OFF.

-

Verify, with planter lowered, radar

speed sensor is pointed at ground,

approximately 35

° below horizontal.

a

a. Refer to sensor documentation.

Hydraulic Hitching Checklist

Page

Marker/Aux valve to Marker

36

Local bypass off (hydraulic hitch only)

17

Fan case drain to low pressure drain port

Fan return line to low pressure return port

All other hydraulic circuits connected

15

Check fan direction

a

and rpm

a. Operate fan briefly and observe rotor blades

spinning toward exit port. Check rpm on seed

monitor.

43

Check hydraulic drive connection

b

b. Perform a “FILL DISK” operation via the seed

monitor.

Mechanical Checklist

Page

Tongue height preset on 3-point

Unfold planter

Tongue front latch hook engaged

25

Side-to-side level at gauge wheels

Marker initial length set

Marker disc angle set

Air System Checklist

Page

Manifold to seed box or hopper seal

-

Add seed lubricant to each air box, prior

to first use, and prior to loading seed

Seed loaded

No air leaks (except from seed box)

-

Hose routings - no sags, no pinches

(check wing-folded & field positions)

-

Hoses fully connected to meters and

locked

Y-tubes turned on to correct rows

Blank disks at unused rows.

80

Shutters set the same on all rows.

76

Start fan. Turn on seed monitor active

air control. Watch for split air vane

movement or air pressure changes.

PDC

Activate the “FILL METER” function of

the monitor. Watch for air vane

movement, or watch meter

pressurization go to zero.

PDC

On a new planter, pre-lubricate the air

system with Ezee Glide Plus.

Set the meter pressurization target to

the recommended value for the crop.

PDC

Row Cleaner Checklist

Page

Check for correct installation of row

cleaners on all rows if equipped.

Check that row cleaners do not catch on

hydraulic hoses.

Carefully watch when folding and unfolding

planter the first time to ensure clearance of

row cleaners.

Frame Mounted Options Checklist

Page

Row cleaner depth setting

Coulter depth and alignment