Gauge wheels, Drive system maintenance, Gauge wheels drive system maintenance – Great Plains 3S-4000F Operator Manual User Manual

Page 84

80

3S-4000

Great Plains Manufacturing, Inc.

195-394M

2014-06-10

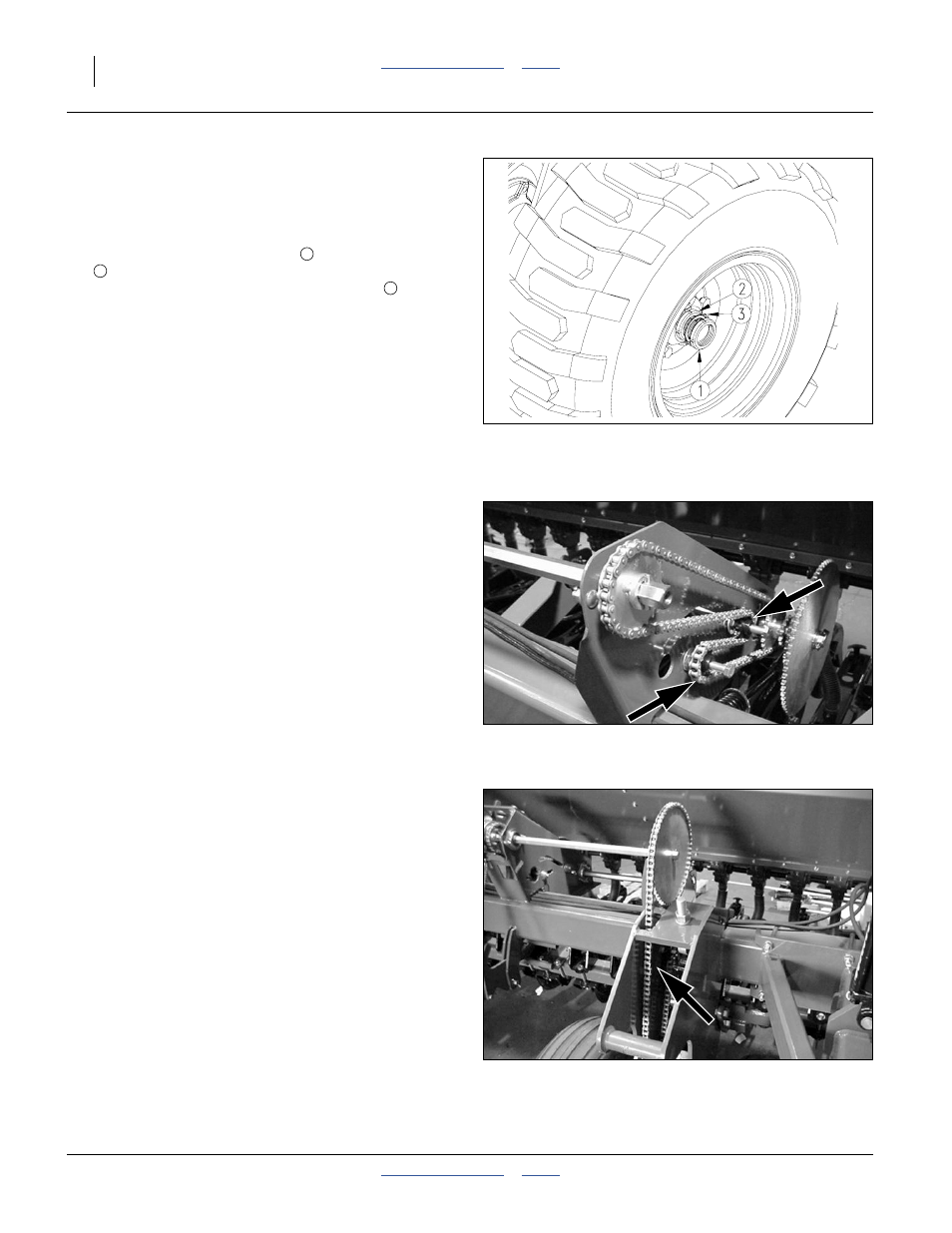

Gauge Wheels

Refer to Figure 89

After several hours of drill use, check gauge wheel

spindle nuts to see that they are tight.

If nuts are loose, back off jam nut

. Tighten spindle

nut

to seat bearings and set rolling resistance. Torque

jam nut to 40 foot-pounds. Crimp lock washer

tabs

onto jam nut.

Drive System Maintenance

Refer to Figure 90 and Figure 91

For proper operation and to prevent downtime and repair,

keep drive chains properly adjusted and lubricated.

Regularly check drive chains for excess slack and wear.

Adjust idlers to remove any excess slack from chains.

Note: Be sure chain is installed with the chain connector

link retainer towards the centerline and the clip

opening (split end) is facing the opposite way of the

chain travel.

Figure 89

Drive Chains and Idlers

18963

1

2

3

Figure 90

Drive Chains and Idlers

18838

Figure 91

Drive Chains and Idlers

18855