Setting hydraulic down-pressure – Great Plains 3S-3000HDF Operator Manual v1 User Manual

Page 55

Great Plains Manufacturing, Inc.

Adjustments

51

2014-07-01

195-441M

Setting Hydraulic Down-Pressure

1.

Lower openers to the ground. Lock hydraulic lever

forward for constant hydraulic flow.

You must lock hydraulic lever forward. See “Opener Opera-

tion” on page 31.

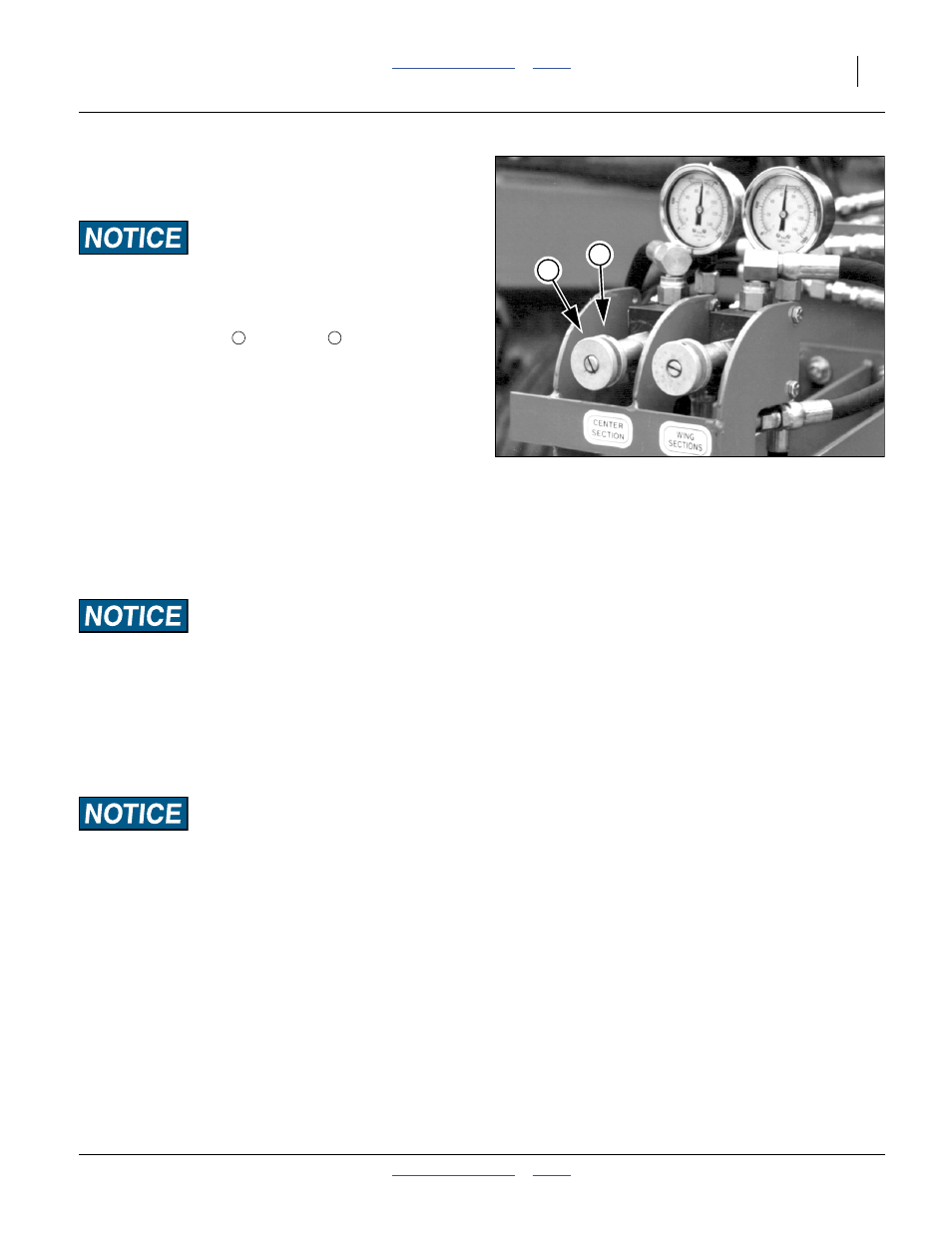

Refer to Figure 46

2.

Release lock disk

. Turn knob

on

pressure-control valve while watching pressure

gauge, turn knob until gauge shows desired

pressure. Turn clockwise to increase pressure. Turn

counterclockwise to decrease pressure.

There is one pressure-control valve for openers on

the center section and one for openers on the wing

sections of the drill.

Refer to the chart on page 50 for approximate force

at the openers for a given pressure setting. As a

general starting point, set hydraulic down pressure to

1200 psi. For most field conditions, adjust down

pressure between 1200 and 1800 psi.

Population Risk:

Do not operate at pressures so high that the gauge wheels

loose traction, or are off the ground, resulting in skips and

poor seed metering.

3.

Once pressure is set, lock knob with lock disk. If

using a non-active hydraulic system to run drill,

unlock the hydraulic remote lever and return it to

neutral.

Machine Damage Risk:

Open-center tractors and tractors with fixed-displacement

pumps are not designed to provide a continuous supply of

pressurized oil to remote valves. Locking hydraulic lever for-

ward on these tractors can cause overheating of hydraulic oil

and tractor damage. After setting opener down pressure,

always return hydraulic lever to neutral.

FigureSpacer

Figure 46

Down-Pressure Valves

26477

1

2

1

2