Priority flow hydraulic systems, Non-active hydraulic system – Great Plains 3S-3000HDF Operator Manual v1 User Manual

Page 37

Great Plains Manufacturing, Inc.

Operating Instructions

33

2014-07-01

195-441M

Priority Flow Hydraulic Systems

On some tractors with load-sensing hydraulics, the circuit

#1 is capable of taking nearly 100 percent of available

hydraulic flow. Operating the openers or markers on

circuit #1 will starve the other circuit, making one function

inoperable.

To operate markers and constant opener down pressure

at the same time, connect the openers to circuit #2 and

the markers to circuit #3.

Non-Active Hydraulic System

To run drill with open-center hydraulics or

fixed-displacement hydraulic pumps requires a Great

Plains kit, part number 194-143A. After installing the kit,

refer to the following instructions for opener operation.

1.

Lower opener frames by pushing forward on tractor

hydraulic lever. Lock lever temporarily in this position

while adjusting opener down pressure.

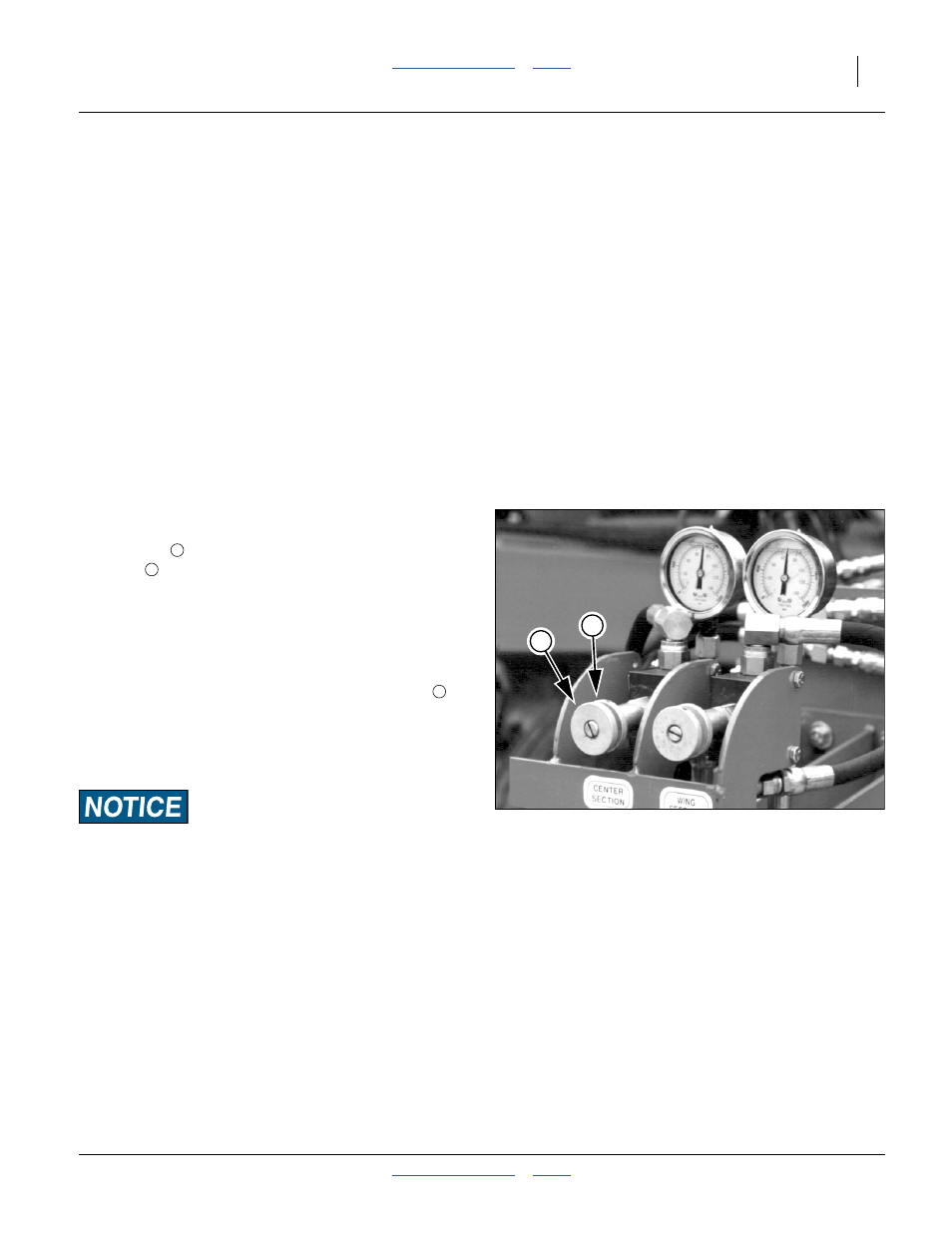

Refer to Figure 25

2.

With tractor hydraulic lever locked forward, release

lock disk

and set down-pressure with adjustment

knob

. Watch pressure gauge and dial in desired

pressure on openers. There is one pressure-control

valve for openers on center section and one for

openers on wing sections of drill.

Note: Rotate knob clockwise to increase pressure and

counterclockwise to decrease pressure.

3.

Once pressure is set, set knobs with lock disks

.

4.

After opener down pressure is set, return tractor

hydraulic lever to neutral. This locks-in the selected

pressure, and opener frames remain fixed in this

position.

Machine Damage Risk: Open-center tractors and tractors

with fixed-displacement pumps are not designed to provide a

continuous supply of pressurized oil to remote valves. Locking

hydraulic lever forward on these tractors can cause overheat-

ing of hydraulic oil and tractor damage. After setting opener

down pressure, always return hydraulic lever to neutral.

Note: On some tractors with very positive remote

hydraulic checks, a slight increase in the reading on

the pressure gauges may occur after tractor remote

lever is returned to neutral. This is caused by back

pressure on opener cylinders and should be

ignored. The net operating pressure on opener

cylinders is maintained at the pressure you

selected while tractor remote lever was held

forward-not at the apparently increased pressure.

Reactivating tractor lever forward will confirm this.

FigureSpacer

Figure 25 - Non-Active

Pressure Control Valves

26477

1

2

1

2

1