Implement locks, Wing lock and flex lock pin use – Great Plains 3P4025AH Operator Manual User Manual

Page 26

22

3P4025AH

Great Plains Manufacturing, Inc.

411-099M

2014-07-29

Implement Locks

Depending on configuration, there are 2 to 4 sets of locks

requiring attention at various phases of operations:

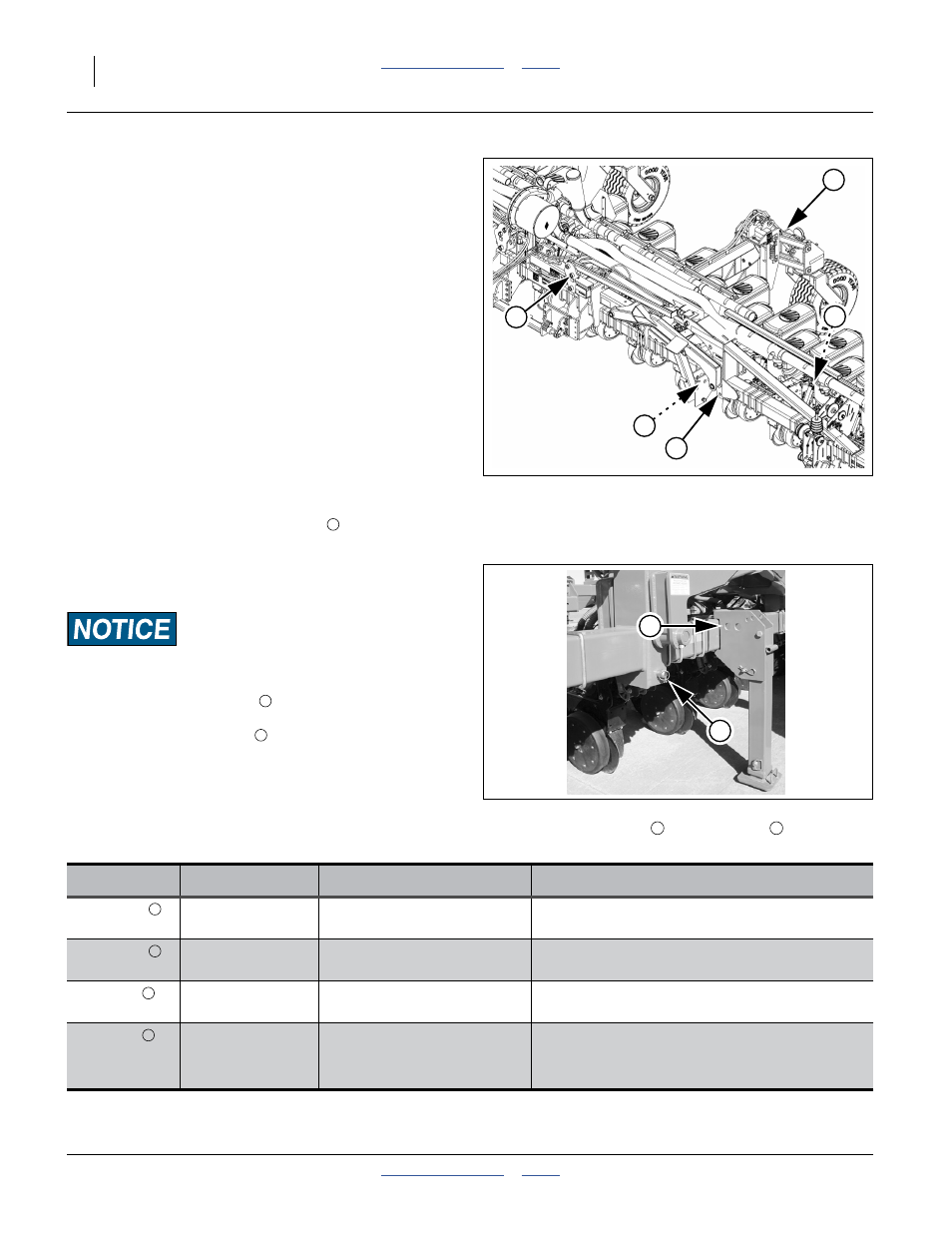

Refer to Figure 12

1.

Wing Flex Lock Pin (see page 22)

Required to stabilize pivot during folding and

unfolding. Used during planting to prevent wing flex.

2.

Wing Lock Pin (see page 22)

Used to keep the wing tool bar at the same height as

the mainframe tool bar. When this pin is installed at

the coupling, the outer wing is either rigid, or can flex

(depending on the planter “flex” configuration).

3.

Lift-Assist Lock Channels (Option, page 23)

These channels, stored on the lift-assist weldments,

are installed on the lift cylinder rods to hold the rear

of the planter at raised.

4.

Row Lock-Up Pins (Option, page 65)

For converting twin-row to single-row.

Wing pins store in the parking stands

when not in use.

Wing Lock and Flex Lock Pin Use

The following table summarizes wing pin use.

Machine Damage Risk:

The

INNER pins

must be IN

and the

OUTER pins

must be OUT

during folding and unfolding,

or machine damage will result.

Figure 12

Lock Locations

36035

5

5

Figure 13

Wing Lock

& Pin Storage

25247

2

5

5

2

1

2

Pin

Location

During

Comments

Wing Lock

Stowed

• Planter Folded

Must be removed from coupling during folding

and unfolding or machine damage will result.

Wing Lock

Tool Bar Coupling

• Planting

Must be removed from coupling during folding

and unfolding or machine damage will result.

Flex Lock

Stowed

• Planting

Must be present in pivot during folding and

unfolding or machine damage will result.

Flex Lock

Wing Arm Pivot

• Folding/Unfolding

• At all times on “Flex Lock”

planters

Must be present in pivot during folding and

unfolding or machine damage will result.

2

2

1

1