5317-5323 wings – Great Plains TC5319 Assembly Manual User Manual

Page 20

16

TC5109-5323

Great Plains Manufacturing, Inc.

566-046E

04/12/2012

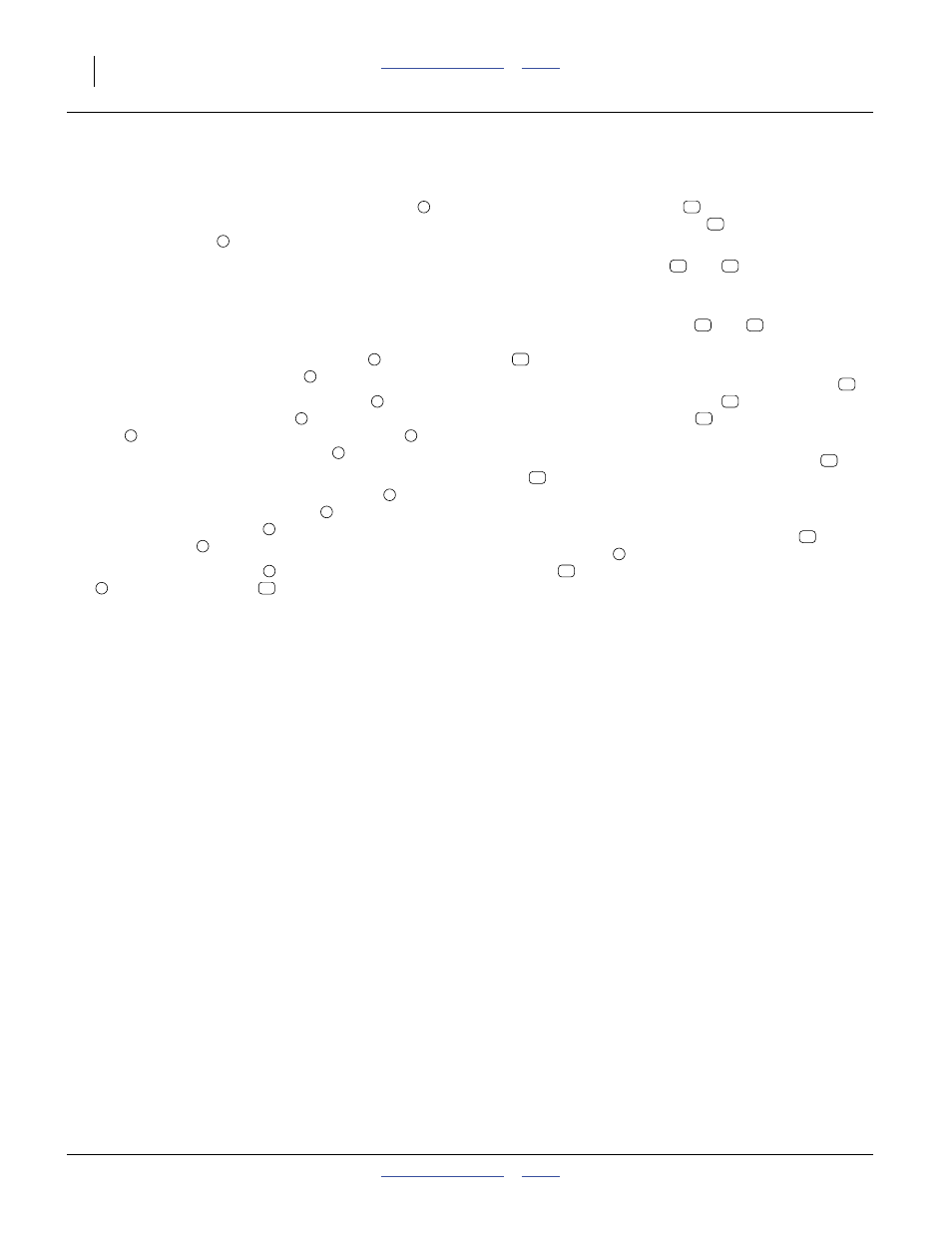

5317-5323 Wings

Refer to Figure 14

74. Carefully align holes in wing frame LH and RH

with holes on center frame hinges. Secure with 1 1/4

x 8 Gr. 8 hex bolt

and 1 1/4 top lock nut.

Note: Tighten bolts snug but do not over-tighten as

wings need to pivot freely. When wing frame is

attached to center frame, set stands (if available)

under outer part of wings to hold wings level for

rest of assembly.

75. Attach lower hole of cylinder bar mount

to ears of

wing frame with 1 x 4 hex bolt

, and 1 lock nut.

76. Attach upper hole of cylinder bar mount

to one

end of wheel arm turnbuckle

with 1 x 3 1/2 hex

bolt

, two 1.5 x 1.0 x.075 machine washers

(one

in each side of cylinder bar mount

), secure with 1

lock nut.

77. Attach other end of wheel arm turnbuckle

to wing

frame ear with 1 x 3 1/2 hex bolt

, two 1.5 x 1.0

x.075 machine washers

(one in each side of cylin-

der bar mount

), secure and 1 lock nut.

78. Attach wing cylinder lug

and wing cylinder mount

with 3/4 x 2 hex bolts

, 3/4 lock washers and 3/4

hex nuts.

79. Attach wing gang mount

to front wing frame

plates with 3/4 x 2 hex bolts

, 3/4 lock washers

and 3/4 hex nuts.

Note: Wing shank mounts

and

are only used on

some models, see machine and attachment layout

drawings in Appendix for proper placement.

80. Install wing shank mounts

and

(model 5323

only) to wing frame plate with 3/4 x 2 1/2 hex bolts

, 3/4 lock washers and 3/4 nuts.

81. Attach base end of the 4 x 36 x 2 fold cylinders

and 4 x 36 x 1.5 fold cylinders

to center fold

bracket with 1 x 3 3/8 pins

, 1.5 x 1.0 x.075

machine washer and 3/16 x 2 cotter pin.

Note: Do not attach rod end of the fold cylinders

and

to wing cylinder lug until fold cylinders have

been purged of air, See “Purging Hydraulic Sys-

tem” on page 24.

82. Attach the 4 x 10 x 1.38 wing lift cylinders

to cylin-

der bar mount

and ear on torque tube with 1 x 3 3/

8 pins

, 1.5 x 1.0 x.075 machine washer and 3/16

x 2 cotter pin.

83. Tighten all bolts to specs, See “Torque Values

1

2

3

7

3

4

5

6

3

4

5

6

3

8

9

10

11

10

12

14

12

14

13

15

16

17

15

16

18

3

17