Hydraulic setup, Hydraulic charge and bleed – Great Plains 3P1006NT Operator Manual User Manual

Page 90

86

3P1006NT

Great Plains Manufacturing, Inc.

151-144M

2011-12-20

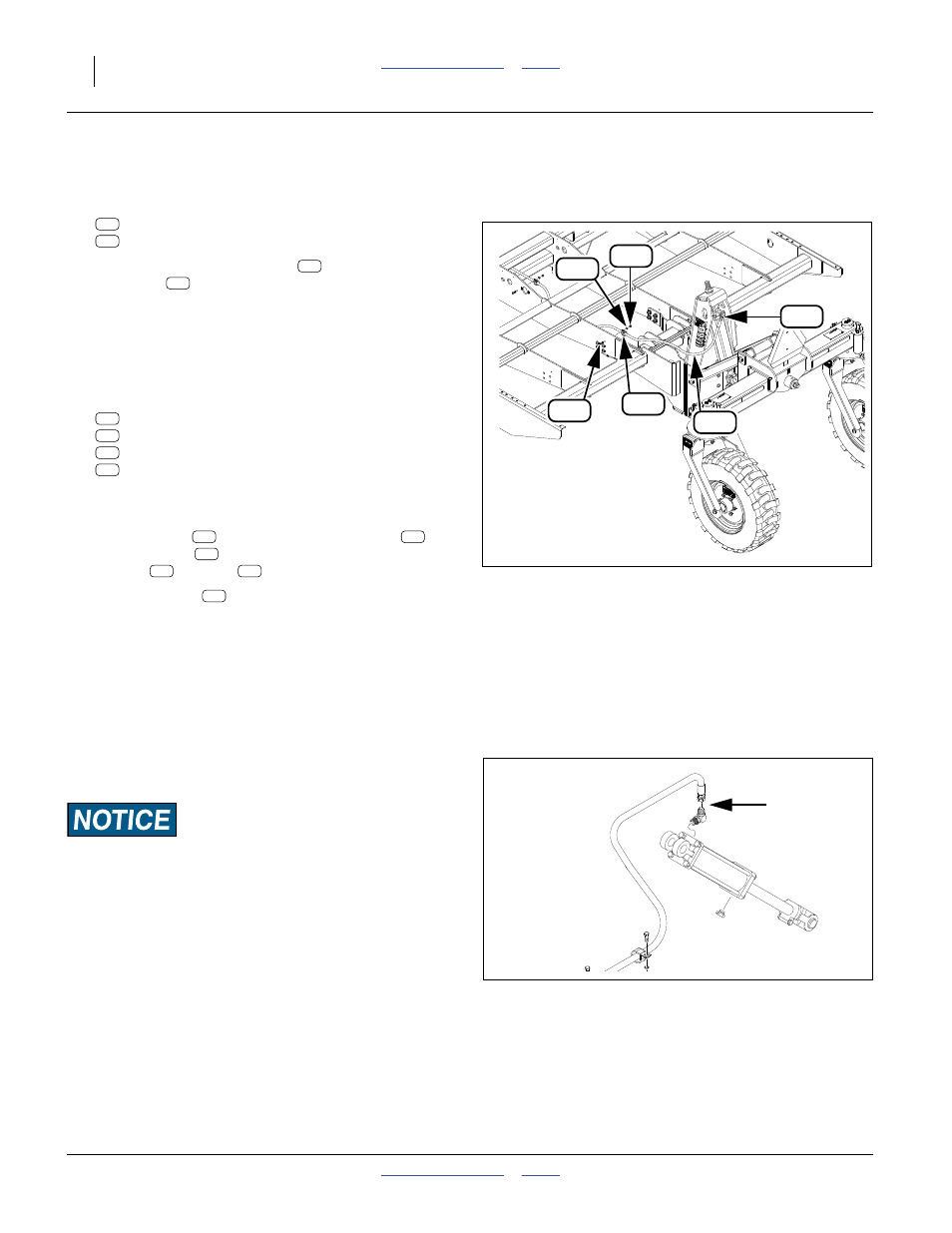

Hydraulic Setup

Refer to Figure 60

28. Select one each:

811-065C EL 9/16MJIC 9/16MORB

841-286C HH1/4R2 134 9/16FJIC 1/2MNPT

29. Secure the FJIC end of hose

to the end port of

the elbow

. Tighten to specification.

30. At the MORB fitting, fully back off the jam nut.

Loosely connect the MORB end of hose to the top

(base end) port of the cylinder. Orient the elbow so

that the hose route is down. Do not tighten ORB

fitting or its jam nut.

31. Select two sets:

800-239C 1.125 WIRING AND TUBE CLIP

802-017C HHCS 3/8-16X1 GR5

804-013C WASHER LOCK SPRING 3/8 PLT

803-014C NUT HEX 3/8-16 PLT

Note: The hose is secured to the frame brace plate at two

points.

32. Place the clip

around the feed-line hose

.

Insert the bolt

. Loosely secure with lock

washer

and nut

. Tighten the nut.

33. Feed-line hose

terminates in a

1

⁄

2

in. male NPT

fitting. Adapt this to the style and size of coupler

required to connect the drill to a hydraulic source for

the next step. The drill does not include a coupler for

this purpose. If fitting the coupler for the tractor to be

used with this drill in the field, apply liquid sealant to

the threads before making the connection. Do not

use plastic tape sealant.

Hydraulic Charge and Bleed

Refer to Figure 61

Bleed pressurized lines only at:

JIC (Joint Industry Conference, 37

° flare) or

NPT (National Pipe Thread, tapered thread) fittings.

Avoid bleeding at:

ORB (O-Ring Boss)

Never bleed pressurized lines at:

QD (Quick Disconnect) fittings.

See “Bleeding Hydraulics” on page 52.

Figure 60

Install Hydraulic Lines

32069

147

156

169

183

134

130

169

183

183

169

130

134

156

147

130

183

134

156

147

183

Figure 61

Lift-Assist Cylinder Bleed

32056