Eyebolt adjustment (s/n a1058w-) – Great Plains 3P1006NT Operator Manual User Manual

Page 55

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

51

2011-12-20

151-144M

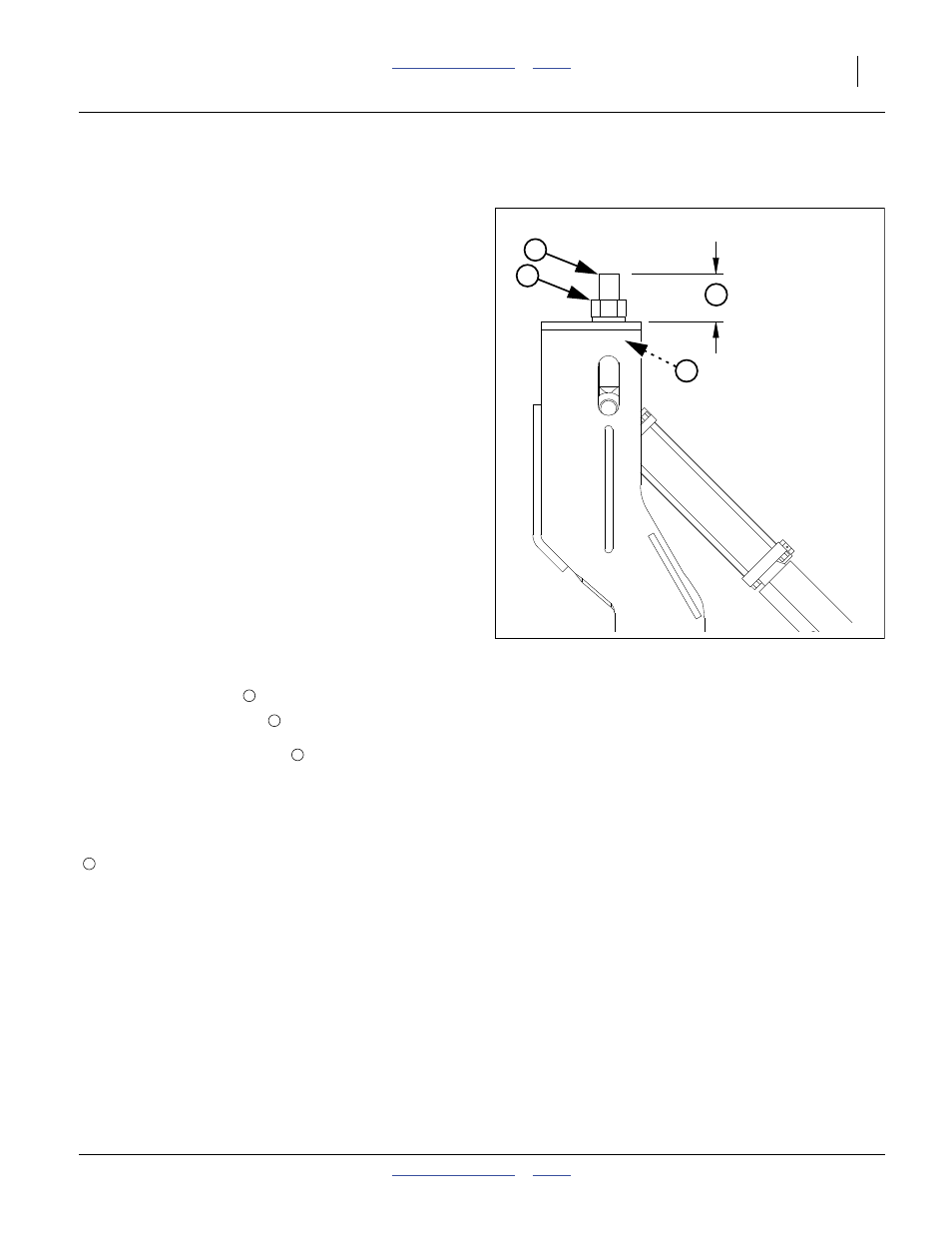

Eyebolt Adjustment (s/n A1058W-)

(applies to drills with serial numbers A1058W-

For serial number A1059W+, see page 50)

Refer to Figure 46

It may occasionally be necessary to make adjustments to

the eyebolts at the top of the lift-assist weldments, for

example:

• drill is out of level side-to-side, or;

• lowered position is too high even with no spacers on

the cylinder rod.

To check side-to-side level:

1.

Move the drill to a flat surface; a concrete pad is

ideal.

2.

Raise the drill. Install the lift-assist lock channel/s.

3.

Lower the lift assist circuit completely. Lower the

tractor 3-point lift arms just enough to keep the drill

reasonably level front-to-back (and keep the openers

off the ground).

4.

Measure from the ground to the rear corners of the

walkboard. If these measurement do not agree

within

1

⁄

8

to

1

⁄

4

inches (5 mm), adjust the eyebolts.

To make adjustments:

5.

Determine which side (or both) to adjust, and what

change in drill height is required.

6.

Hitch the drill to the tractor’s 3-point lift arms. Raise

the drill, and support the rear tool bar on jack stands.

7.

Loosen the jam nut

.

8.

Rotate the adjuster nut

(under weldment top, not

visible in figure) by the amount of height change

required. Move the eyebolt

lower increases height.

Moving the eyebolt higher decreases height.

9.

Tighten the jam nut.

10. Lower the drill and check the setting.

The factory setting for eyebolt reveal is:

3 in. (76 mm)

Figure 46

Lift-Assist Eyebolt (A1058W-)

28387

2

1

3

4

1

2

3

4