Troubleshooting – Great Plains 3P1006NT Operator Manual User Manual

Page 44

151-144M

2011-12-20

40

3P1006NT

Great Plains Manufacturing, Inc.

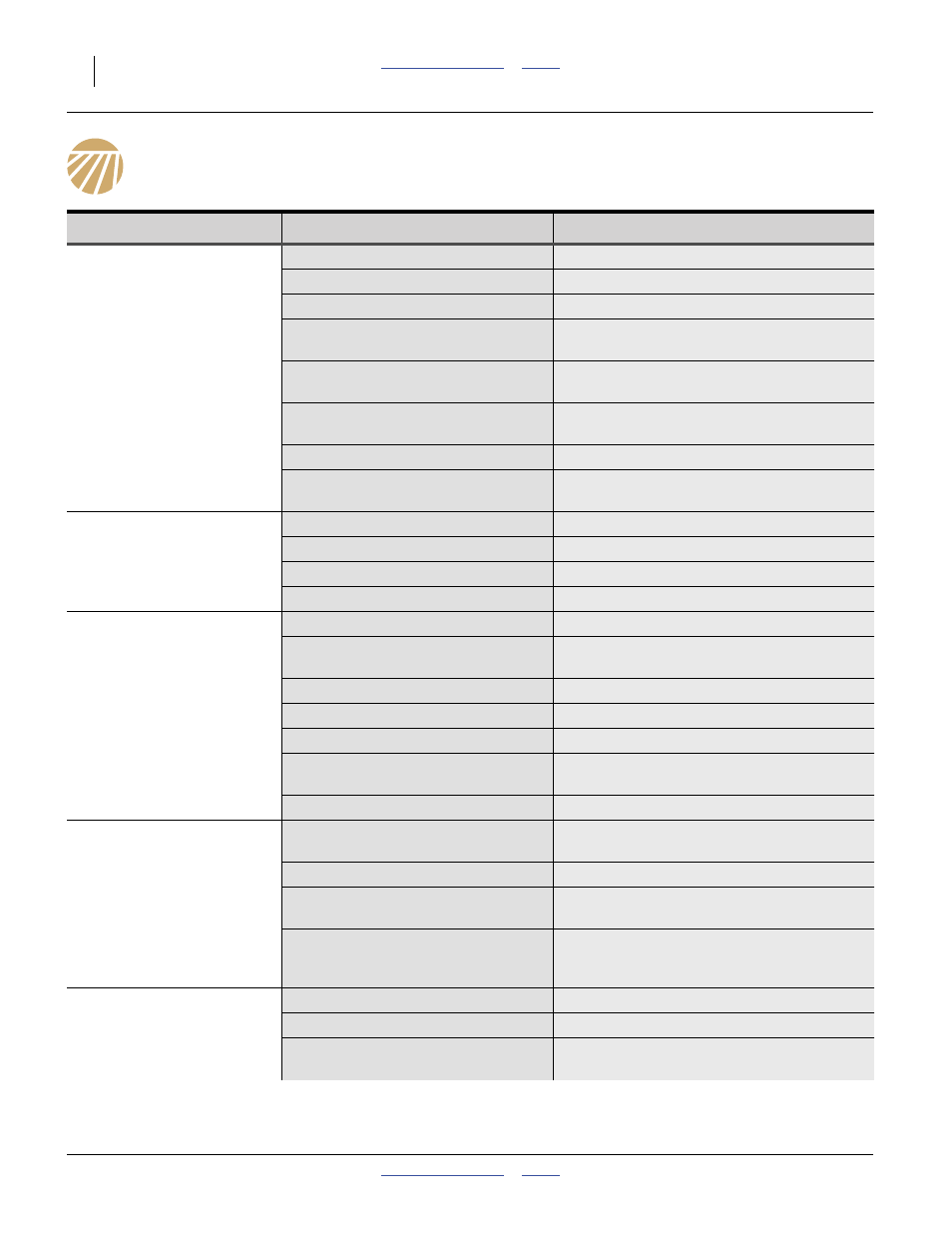

Troubleshooting

Problem

Cause

Solution

Uneven seed spacing or

uneven stand

Excessive field speed.

Reduce field speed.

Feed cups plugging.

Clean out feed cups.

Seed tubes plugging.

Clean out seed tubes.

Opener discs not turning freely.

See “Opener discs not turning freely” in this

Troubleshooting section.

Ground drive wheel slippage

Check tire pressure and frame height.

Solution may require drier conditions.

Seed cups too wide

Use faster Drive Type speed and close feed

cup flutes to a more narrow position.

Chain skipping.

Check chain slack and wear.

Mud build-up on Seed-Lok

®

wheel

Lock-up Seed-Lok

®

(page 38) or wait for

drier conditions.

Uneven seed depth

Excessive field speed.

Reduce field speed.

Planting conditions too wet.

Wait until drier weather.

Drill not level

Casters lifting drill

Set lift-assist circuit to Float.

Opener discs not turning

freely

Trash or mud build up on disc scraper. Adjust scraper (page 37).

Scraper adjusted too tight, restricting

movement.

Adjust scraper (page 37).

Failed disc bearings.

Replace disc bearings.

Bent or twisted opener frame.

Replace opener frame.

Planting conditions too wet.

Wait until drier weather.

Too much opener down pressure.

If opener discs turn freely by hand but not in

field, reduce down pressure (page 37).

Incorrect press wheel adjustment.

Readjust press wheel (page 39).

Actual material rate

different than desired

Incorrect frame height, axle setting,

tire size or tire inflation.

Check ground drive tires (page 65), frame

height (page 16) and axle setting (page 32).

Improper tire size or air pressure.

Check tire size and air pressure (page 65).

Build up of seed treatment in feed

cup.

Clean out seed treatment from feed cups.

Incorrect rate adjustment.

Check gearbox, sprocket, seed rate handle

and seed door settings. Perform calibration if

not already done.

Excessive seed cracking

Excessive field speed.

Reduce field speed.

Feed cup flutes not open enough.

Open feed cups to a wider position.

Feed cup door handle not open

enough.

Open feed cup door handle to a lower

position.