Caster brake adjustment (s/n a1058w-), Pressure plate adjustment – Great Plains 3P1006NT Operator Manual User Manual

Page 49

Great Plains Manufacturing, Inc.

Maintenance and Lubrication

45

2011-12-20

151-144M

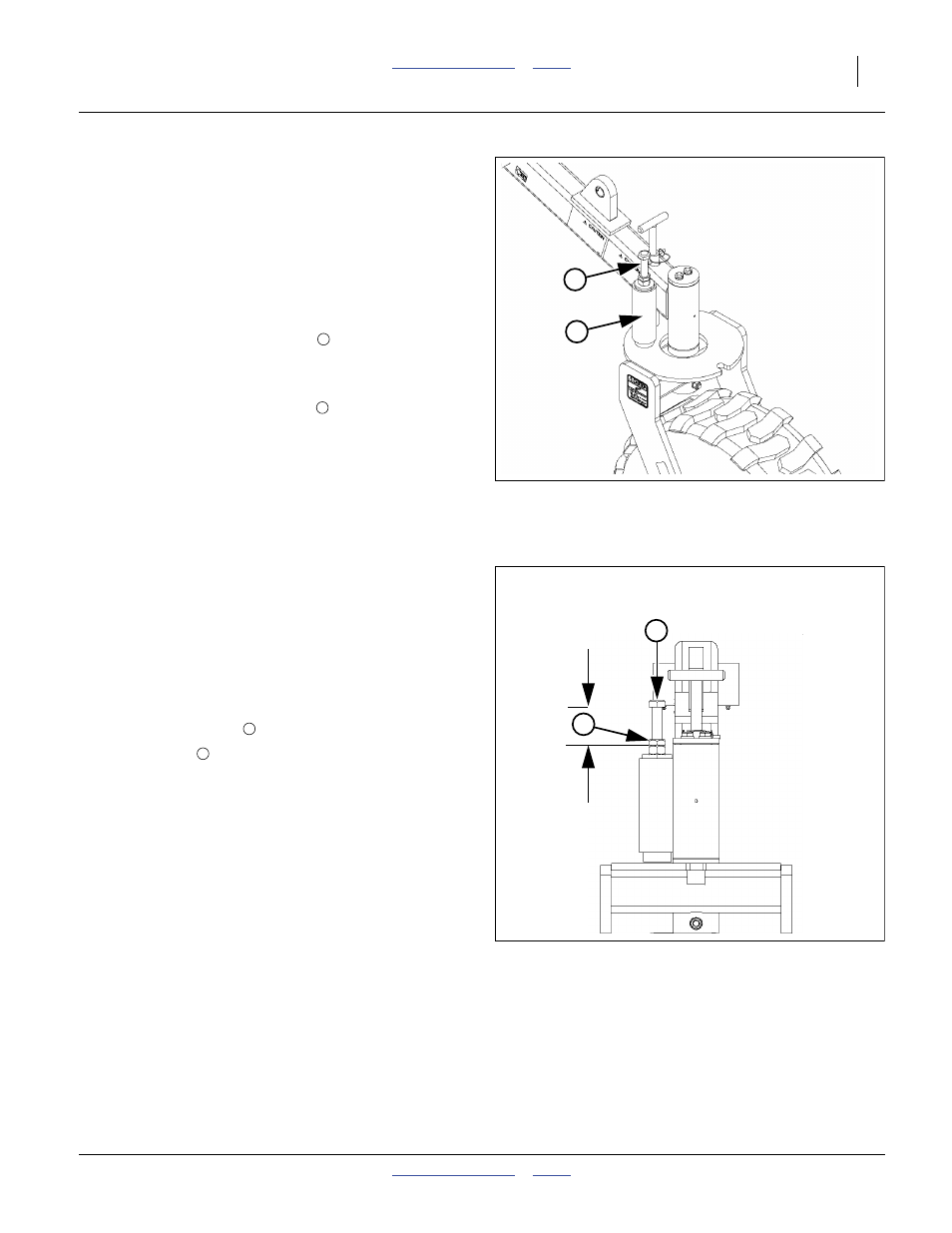

Caster Brake Adjustment (s/n A1058W-)

(applies to drills with serial numbers A1058W-

for serial number A1059W+, see page 44)

Refer to Figure 35

The rear lift-assist wheels each have independent

adjusters for the caster pivot. The adjustments will vary

depending on different field-to-field conditions as well as

road transport conditions.

If the caster is oscillating during transport turns or in field

use, adjust the pressure plate bolt

.

Refer to Figure 36

The factory setting for both adjustments is

1

3

⁄

4

in. (4.4 cm) from the face of the bolt head to the top

of the weldment, this measurement is a starting point

and will need to be fine tuned from field-to-field as

conditions vary. Depending on conditions, adjustment

may be needed to go from field to road transport. If

caster brake components are ever replaced, return the

bolts to the factory setting.

Pressure Plate Adjustment

1.

Loosen the jam nut

.

2.

Turn the bolt

clockwise until the spring is fully

compressed.

3.

Back the bolt out

1

⁄

4

in (6mm).

4.

Tighten the jam nut.

Caster Pressure Plate and Tube:

The tube acts as a pivot brake

, and helps prevent

caster oscillation during transport.

Figure 35

Rear Caster Adjustments

(left side shown)

31631

2

1

1

2

Figure 36

Rear Caster Adjustment Bolts

(right side shown)

31632

1

3

⁄

4

in.

4.4 cm

2

3

3

2