Truss tube tension, Tool bar height, Truss tube tension tool bar height – Great Plains 3S-4000HDF Operator Manual User Manual

Page 88

84

3S-4000HD/HDF

Great Plains Manufacturing, Inc.

195-067M

2013-06-13

Truss Tube Tension

The truss tubes help hold the center tool bar

perpendicular to the tongue and straight under load.

After some time, slack can develop in the truss tubes.

Refer to Figure 95

Check that truss tubes

are providing a small amount

of tension to help hold draft load from tool bars. If not,

adjust truss length at front clevis ends

.

Check truss tube tension if tool bar height is adjusted.

See “Tool Bar Height” on page 84

Also check wing box alignment when checking truss

tubes. See “Wing Box Alignment” on page 81.

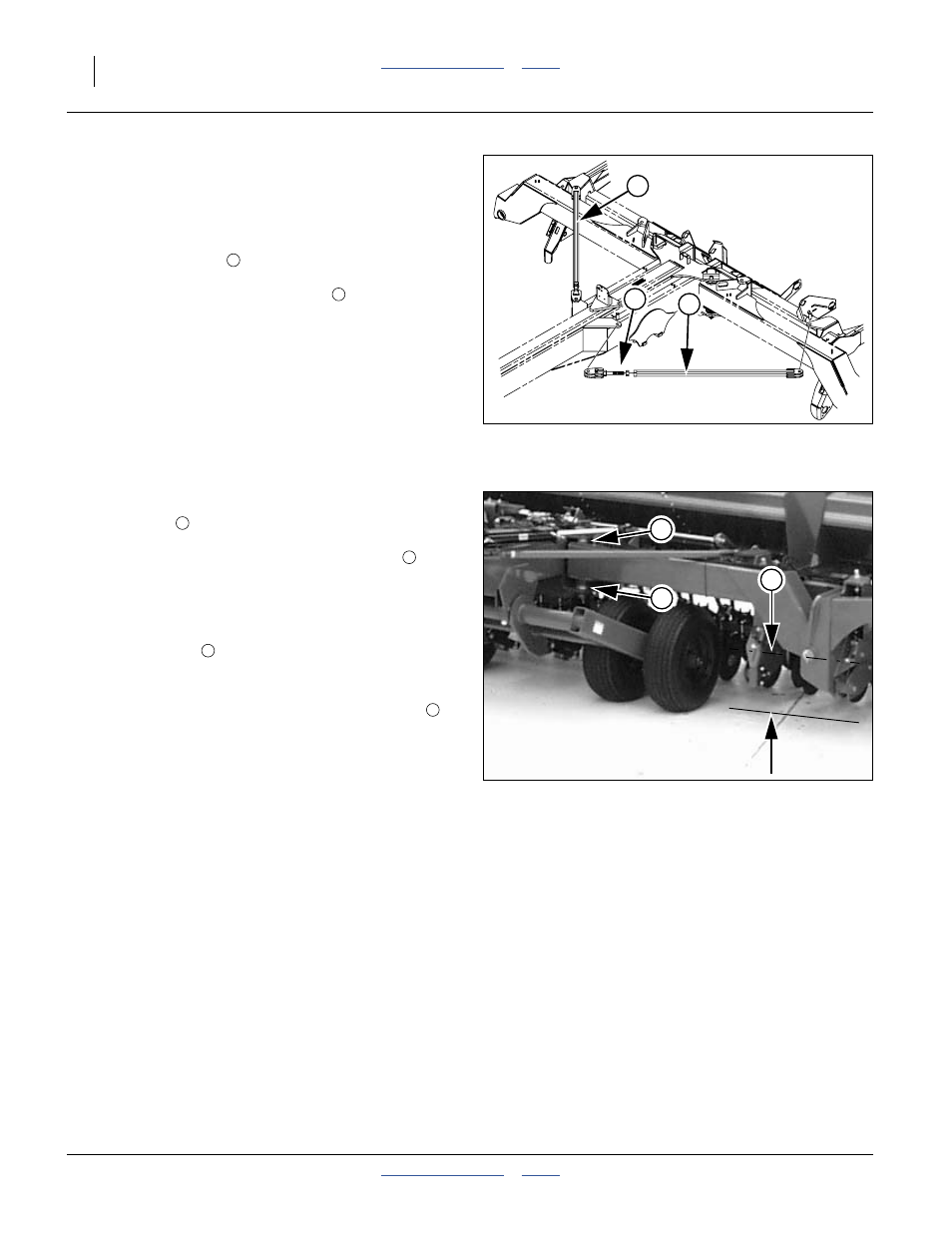

Tool Bar Height

Refer to Figure 96

Tool bar height

is factory set and normally does not

require adjustment. If you tear down the drill for repair, or

if the tool bar is visibly not level, spacer washers

on

vertical pivot pins allow for a small amount of tool

bar-height adjustment.

To check tool bar height, park drill on a level surface, and

check for correct tire inflation. Measure from ground to

horizontal pivot pin

. If dimension on either side of drill

varies more than

1

⁄

4

inch (6.4 mm), adjust tool bar

height.

To adjust tool bar height, reposition spacer washers

.

First lower openers and set enough opener down

pressure to help balance frame. Raise tool bar by

removing spacer washers from top of the vertical pivot

and placing them on bottom side of pivot. Lower tool bar

by removing spacer washers from bottom of vertical pivot

and placing them on top of pivot.

Figure 95

Truss Tubes

18811

1

1

2

1

2

Figure 96

Tool bar Height

18845

1

2

2

1

2

1

2