Replacing shear pins, Shaft alignment, Contact drive spring tension – Great Plains PD8070 Operator Manual User Manual

Page 37

1/24/2006

401-266M

35

Maintenance and Lubrication

Replacing Shear Pins

Refer to Figure 29

The cotter pins (1) that connect shafts to transmission

will shear when an excessive load is put on the shafts.

Infrequent or improper lubrication causes binding of

moving parts within the planter. This binding will cause

cotter pins to shear, thus preventing breakage of planter

parts.

Check for binding by turning drive shaft with all seed

hoppers installed and seed meters engaged. If drive

shaft is hard to turn, disengage one seed-meter clutch

at a time to find the problem clutch.

Improper shaft alignment can also cause pins to shear.

Refer to Shaft Alignment, page 35.

When drill shaft can be turned freely by hand, replace

the cotter pin.

IMPORTANT: Replace cotter pins with cotter pins of the

same size. Do not replace with other type pins.

Shaft Alignment

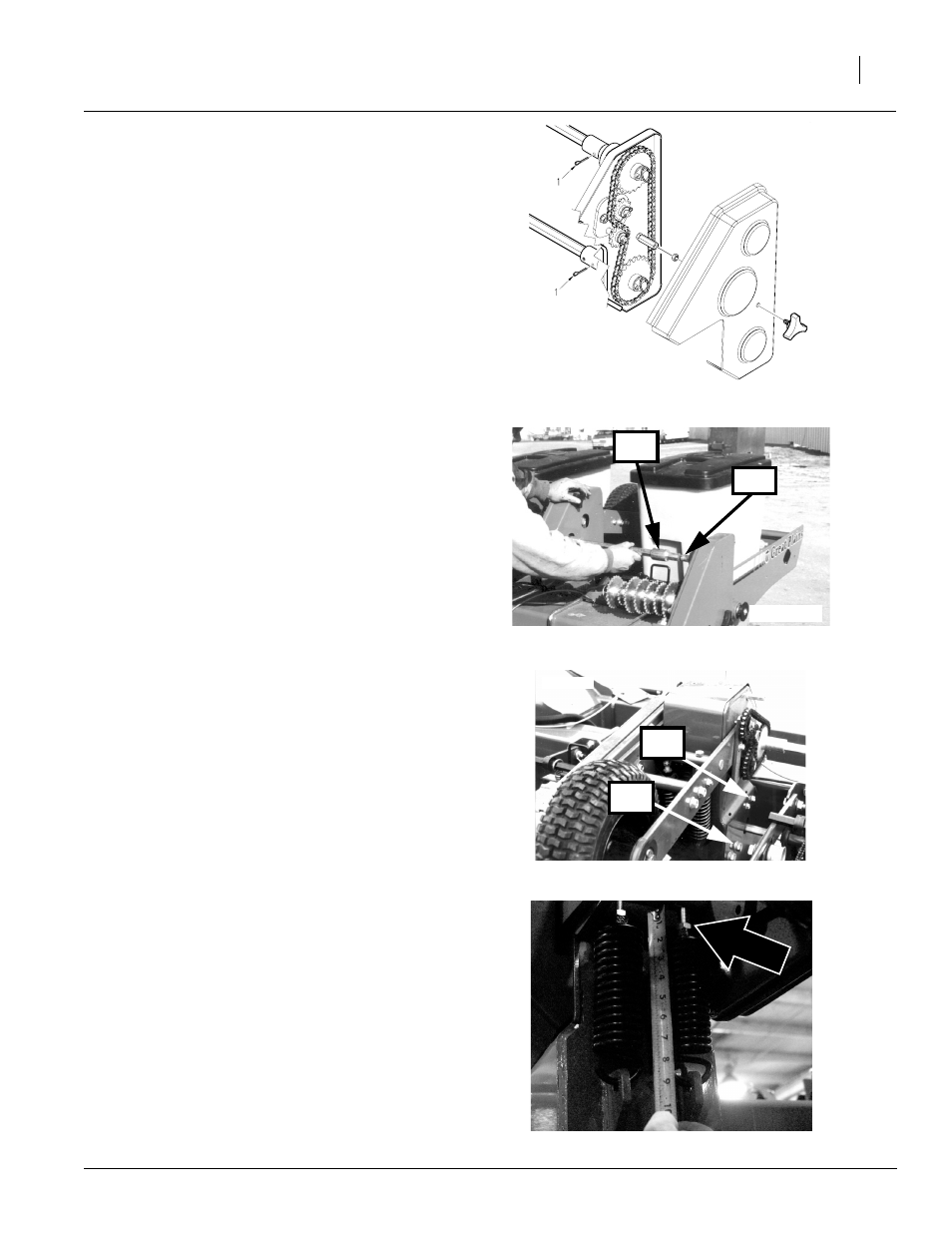

Refer to Figure 30

Improper shaft alignment can cause pins to shear. To

function properly, transmission shafts must be aligned

and level. If the planter is consistently shearing pins,

follow these steps to check and adjust the shafts.

1.

Check that transmission input shaft (1) and trans-

mission shaft (2) are aligned. Remove cotter pin

from coupler sleeve. Pull coupler sleeve back and

observe the shafts.

Refer to Figure 31

2.

If shafts are not aligned, adjust contact-drive tower.

Loosen mounting bolts (1) on both sides of tower.

Adjust tower position until shafts are aligned.

3.

Retighten tower mounting bolts. Slide coupler

sleeve over transmission input shaft and reinsert

cotter pin.

Contact Drive Spring Tension

Refer to Figure 32

The contact drive spring tension is preset between 1” to

1 1/4” at the factory. Occasionally, due to planting

height or planting conditions, it may be necessary to

adjust the spring tension to keep the contact drive tire

from slipping.

Adjust tension until contact drive tire has enough ten-

sion to stay in contact with gauge wheel. NOTE: DO

NOT increase tension so much that contact drive

tire resists turning.

16862

Figure 29

Transmission Cotter Pins & Shear Pins

16832

1

2

Figure 30

Transmission Input Shaft Alignment

16849

1

1

Figure 31

Contact Drive Housing Adjustment

Figure 32

Contact Drive Spring Tension (Factory Setting)