Great Plains PD8070 Operator Manual User Manual

Page 34

PD8070

401-266M

1/24/2006

32

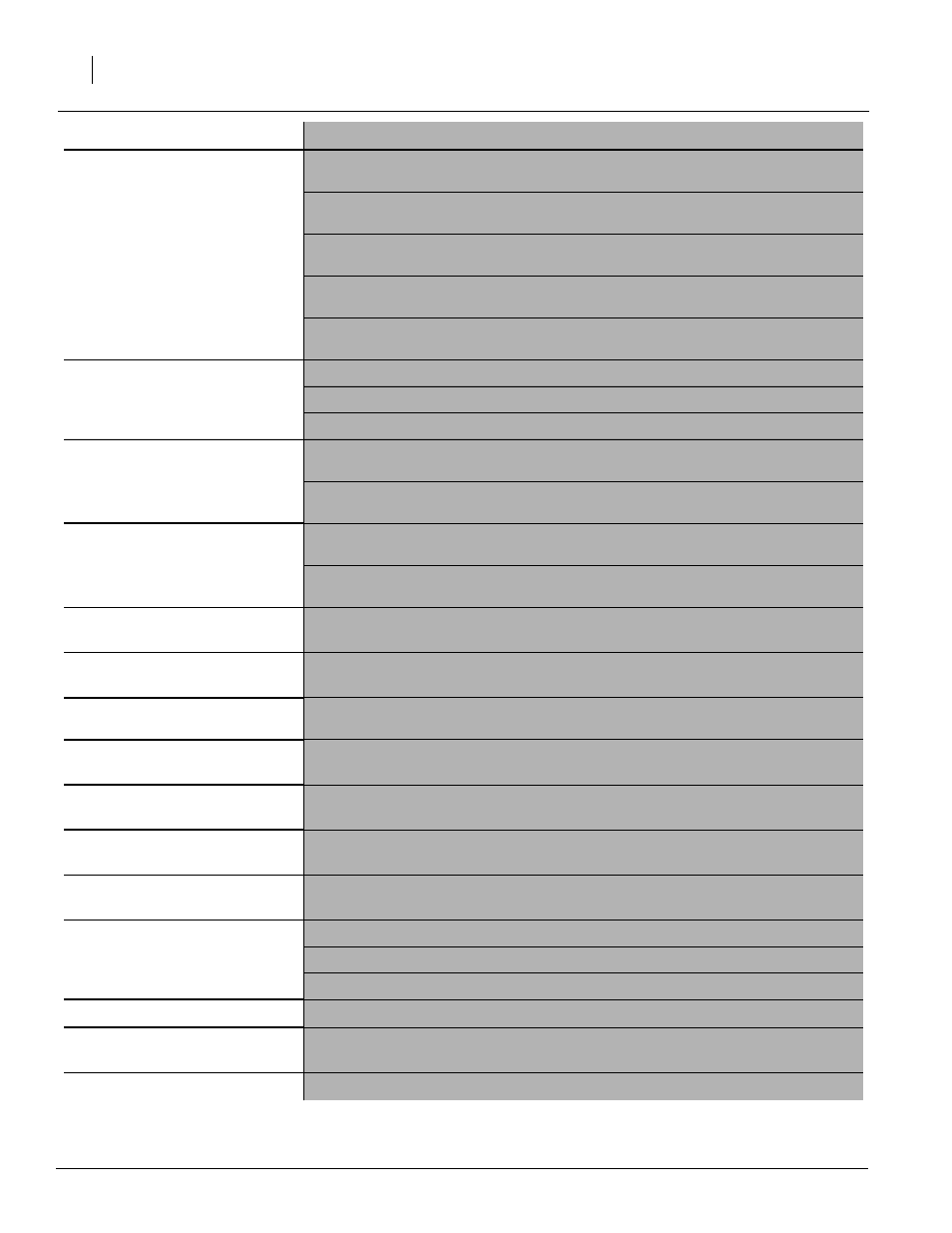

Seed spacing not as indicated in

charts.

Check that tires are inflated to proper pressure. Refer to Tire Inflation Chart,

“Appendix,” page 52.

Examine seed for inconsistent size. Do field check and adjust sprockets accord-

ingly.

Check that correct sprockets are installed on the transmission shafts. Refer to

Planting Rate Charts, “Adjustments,” beginning on page 20.

Excessive speed may be causing row unit bounce. Reduce ground speed when

planting.

Charts are approximate. Slight variations due to wear may produce seed spacing

variations.

Scattering of seeds.

Reduce planting speed.

Check seed tube for proper installation.

Examine seed tube for wear or damage. Replace seed tube if necessary.

Seed tubes and/or openers

plugging.

Do not allow planter to roll backward when lowering. Lower planter only when

tractor is moving forward.

On four-wheel-drive tractors, avoid turning tractor when planter is down and sta-

tionary.

Inconsistent seed depth.

Increase down pressure on row unit. Refer to Row Unit Adjustments, “Adjust-

ments,” page 20.

Inspect seed tube for plugging or improper installation. Check that seed tubes are

hooked properly in shank of row unit.

None of the row units are

planting.

Pin between counter-shaft and seed transmission sheared. Repair cause of pin

shearing and replace pin.

Opener disks and side gauge

wheels plugging.

Adjust gap between opener disks and side gauge wheels. Refer to Side Gauge

Wheels, “Adjustments,” page 20.

Fertilizer hopper not metering.

Pin between counter-shaft and fertilizer transmission sheared. Repair cause of pin

shearing and replace pin.

Closing wheels leave severe

imprint in soil.

Reduce down pressure on closing wheels. Refer to Row Unit Adjustments,

“Adjustments,” page 20.

Closing wheels not firming soil

around seed.

Increase down pressure on closing wheels. Refer to Row Unit Adjustments,

“Adjustments,” page 20.

Closing wheel running on top of

seed furrow.

Realign closing wheels. Refer to Row Unit Adjustments, “Adjustments,” page 20.

Repeated shearing of shaft cotter

pin.

Drill shaft not aligned properly. Loosen bearing and align shaft.

Drive wheel chain consistently

falls off.

Chain may be too long. Remove offset link.

If chain links are stiff, oil or replace chain.

Check if trash is dislodging chain; if so, install trash guards.

No seed being planted.

Check that seed hopper is full of seed.

Opener disks and side gauge

wheels plugging.

Adjust gap between opener disks and side gauge wheels. Refer to Side Gauge

Wheels, “Adjustments,” page 20.

Planter will not lower.

Check that pressure and return hoses are fully engaged in SCV outlets.

Problem

Possible Cause and Solution