Great Plains PD8070 Operator Manual User Manual

Page 35

1/24/2006

401-266M

33

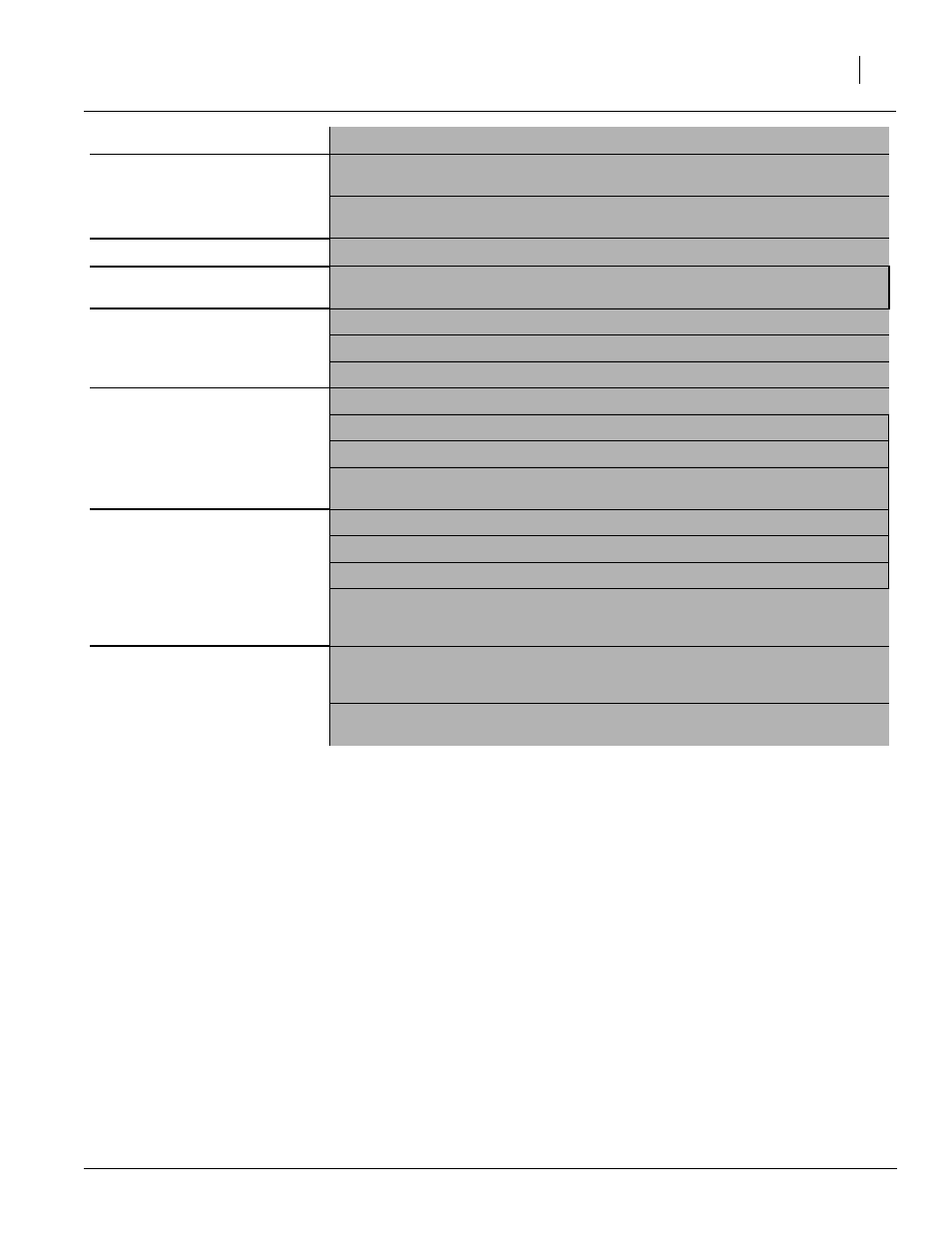

Troubleshooting

Planter frame raises or lowers

slowly.

Lower tractor hydraulic pressure. Tractor operating pressure must be a minimum

of 1500 psi.

Operate tractor with flow control lever in the unrestricted position. Refer to your

tractor operator’s manual.

Erratic or uneven lift.

Check for air in hydraulic system. Bleed system of air if necessary.

Planter will not raise.

Tractor hydraulic system bypassing oil. Readjust tractor’s hydraulic lever linkage.

Refer to your tractor operator’s manual.

Markers not alternating.

Marker hoses not connected to marker valve correctly.

Check for air in marker valve. Bleed marker hydraulic system.

Marker valve defective. Replace valve. See your Great Plains dealer.

Marker floats off ground.

Air in hydraulic system. Bleed marker lift cylinder.

Alternator valve defective. Replace valve. See your Great Plains dealer.

Check for leaks in tractor hydraulic remote.

Marker cylinder not dropping down into J-slot. (Hose loop too short.) Lengthen

marker hydraulic hose loops.

Hydraulic marker functioning

improperly.

Check all hose fittings and connections for air and oil leaks.

Check tractor hydraulic oil level.

Check all bolts and fasteners.

If markers do not alternate: check tractor flow controls and set to maximum oil

flow. If problem still exists, disassemble valve and check for contamination or

spool damage.

Blade does not mark.

The maximum marker down float is limited by the slot in the pivot link. If the blade

does not drop down to follow depressions in the field, make sure the marker cylin-

der is fully extended.

The blade may be reversed to pull dirt in or throw dirt out depending on soil condi-

tions.

Problem

Possible Cause and Solution