Coulter depth, Opener seeding depth, Side gauge wheels – Great Plains PD8070 Operator Manual User Manual

Page 27

1/24/2006

401-266M

25

Adjustments

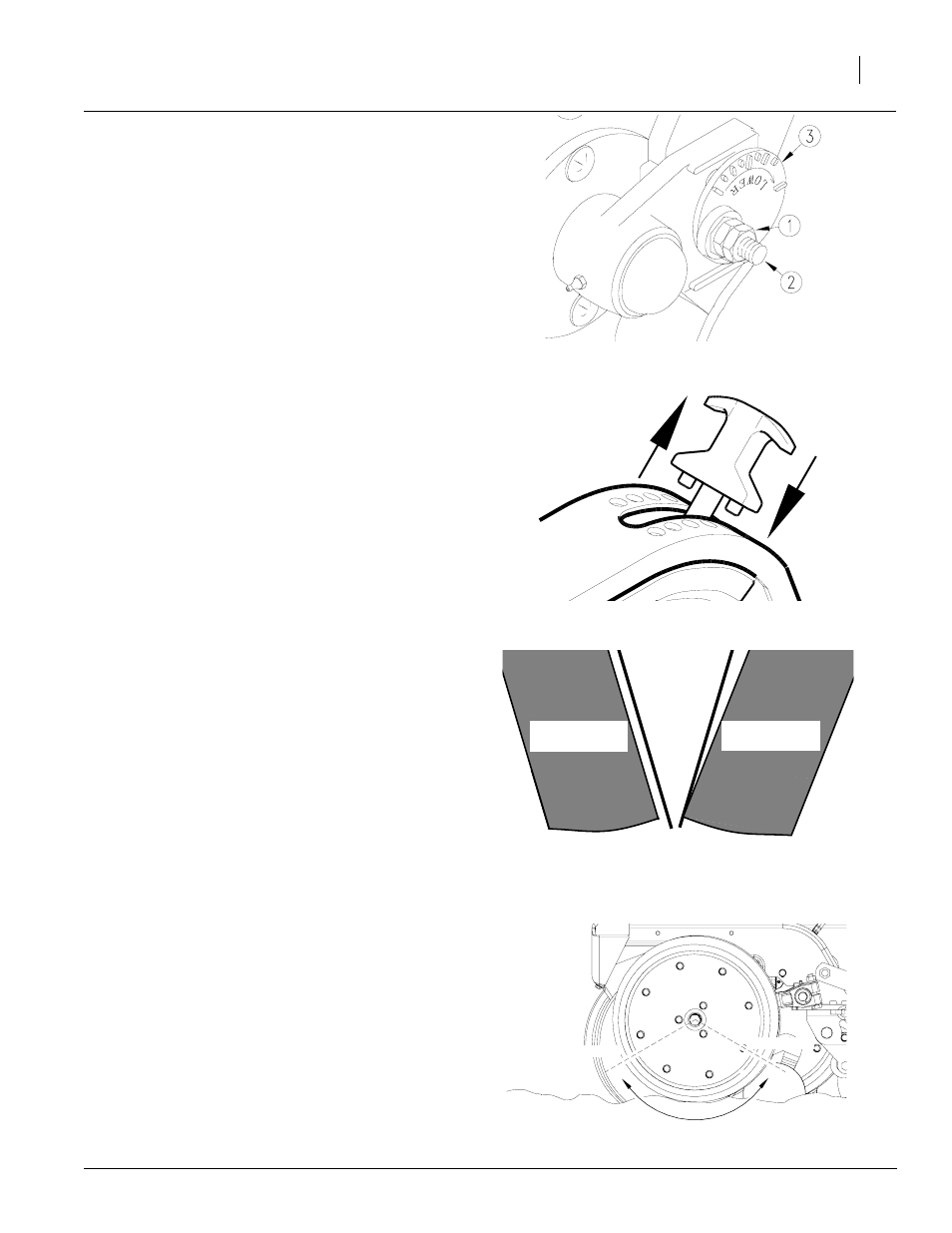

Coulter Depth

Optional coulters allow row unit to penetrate tough

ground conditions. Adjust coulters to run at the same

depth as the opener disks.

Refer to Figure 14

1.

To adjust coulter depth, loosen 3/4-inch jam nut (1)

and 3/4-by-3-inch hex bolt (2).

2.

By turning cam hex (3), rotate cam casting to the

desired height. Each notch represents about 1/4

inch of depth.

3.

Torque bolt and jam nut to values recommended on

Torque Values Chart, “Appendix,” page 52.

Opener Seeding Depth

Seeding depth is controlled by gauge wheels mounted

on the sides of the opener disks.

Refer to Figure 15

To adjust seeding depth:

1.

Raise planter to remove weight from side gauge

wheels.

2.

Raise and move T-handle.

• Move T-handle forward for deeper seeding depth.

• Move T-handle back for shallower seeding depth.

3.

Move T-handles on all row units to the same loca-

tion.

Side Gauge Wheels

Refer to Figure 18

The side gauge wheels have two, interrelated

adjustments:

• angle of side gauge wheel, and

• distance between side gauge wheel and opener

disk.

Refer to Figure 17

Adjust side gauge wheel angle so the wheels contact

the opener disks between 4 and 8 o’clock.

At the same time, keep the side gauge wheels close to

the opener disks so openers do not plug with soil or

trash but far enough out so the disks and wheels turn

freely.

To adjust side gauge wheels:

1.

Raise implement slightly to remove weight from

side gauge wheels.

15053

Figure 14

Row Unit Mounted Coulter

12345

Figure 15

Opener Depth Adjustment

Side Gauge

Wheel

Side Gauge

Wheel

Opener

Disks

Incorrect

Correct

Figure 16

Side Gauge Wheels

17812

8 o’clock

4 o’clock

Figure 16

Side Gauge Wheels