1 x 12 closing wheel option – Great Plains PD8070 Operator Manual User Manual

Page 28

PD8070

401-266M

1/24/2006

26

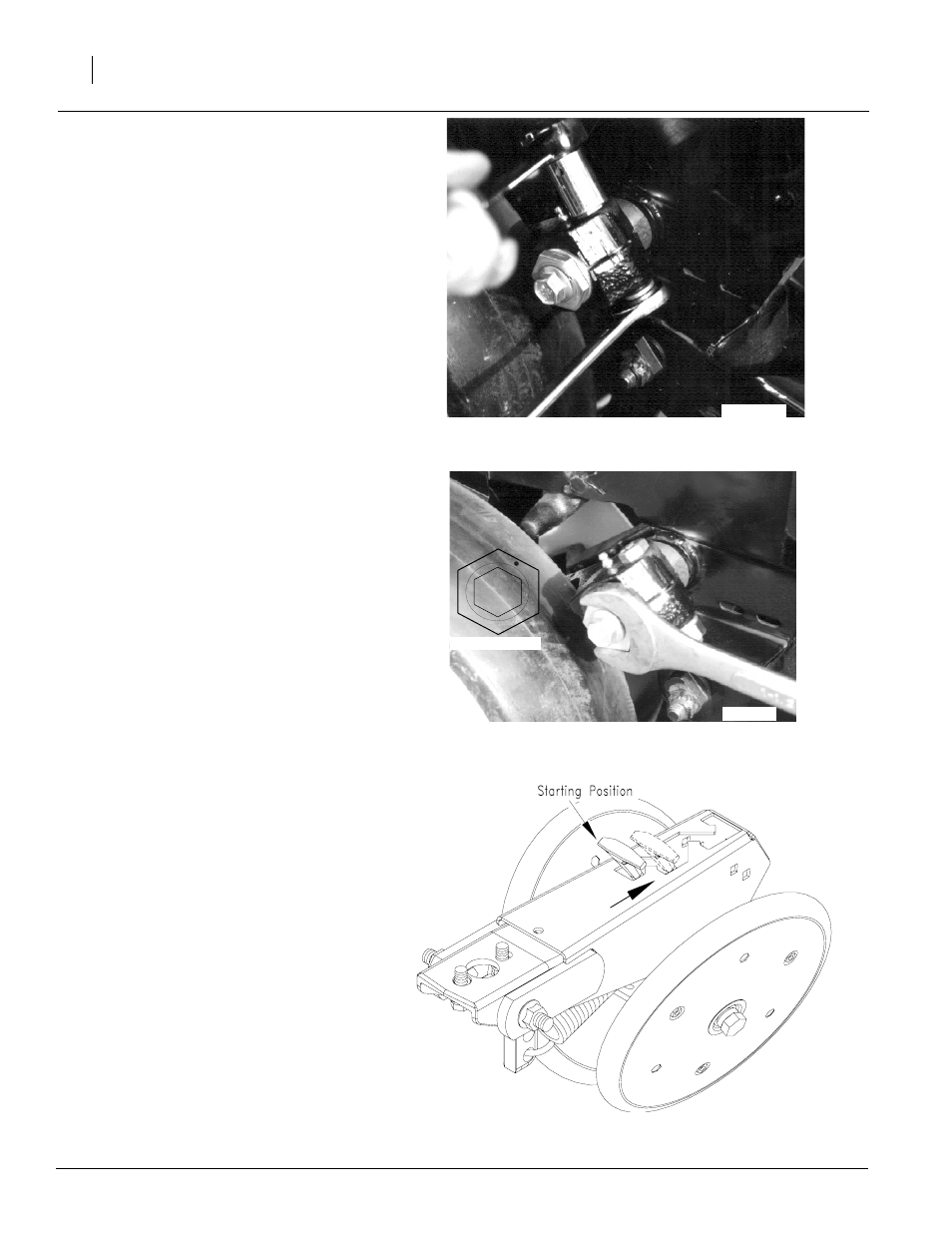

Refer to Figure 18

2.

Loosen hex-head bolt. Move wheel and

arm out on o-ring bushing.

Refer to Figure 19

3.

Loosen pivot bolt. Turn hex adjuster so

roll pin (1) is at 1 o’clock. Use this as the

starting point for adjustments.

4.

Move wheel arm in so side gauge wheel

contacts opener disk. Tighten hex-head

bolt to clamp arm around bushing and

shank.

5.

Check the wheel-to-disk contact. Lift

wheel and arm. When let go, the wheel

should fall freely.

• If wheel does not contact disk from 4

to 8 o’clock, move hex adjuster until

wheel is angled for proper contact with

disk.

• If wheel does not fall freely, loosen

hex-head bolt and slide wheel arm out

just until wheel and arm move freely. Re-

tighten hex-head bolt.

6.

Keep turning hex adjuster and moving

wheel arm until the wheel is adjusted

properly. When satisfied, tighten pivot

bolt to 110 foot-pounds.

1 x 12 Closing Wheel Option

The closing wheels can be adjusted for down

pressure, alignment and offset.

Refer to Figure 20

Down Pressure. Adjust the closing wheels

so they have enough down force to close

the seed trench without unnecessary

compaction.

Start with T-handle in first notch. If the seed

trench does not close, move handle to next

notch and try again. Keep moving handle

back just until the seed trench closes.

17916

Figure 18

Loosen Hex-Head Bolt

Starting Point

17914

Figure 19

Turn Hex Adjuster

17888

Figure 20

Closing Wheel Down Pressure