Spreader and scraper, Disk, Gauge wheels – Great Plains PT8030 V1012 Operator Manual User Manual

Page 49: Caution

47

Section 7 Maintenance and Lubrication

PT6030 and PT8030 Pull-Type Planter 401-032M

10/10/12

Great Plains Mfg., Inc.

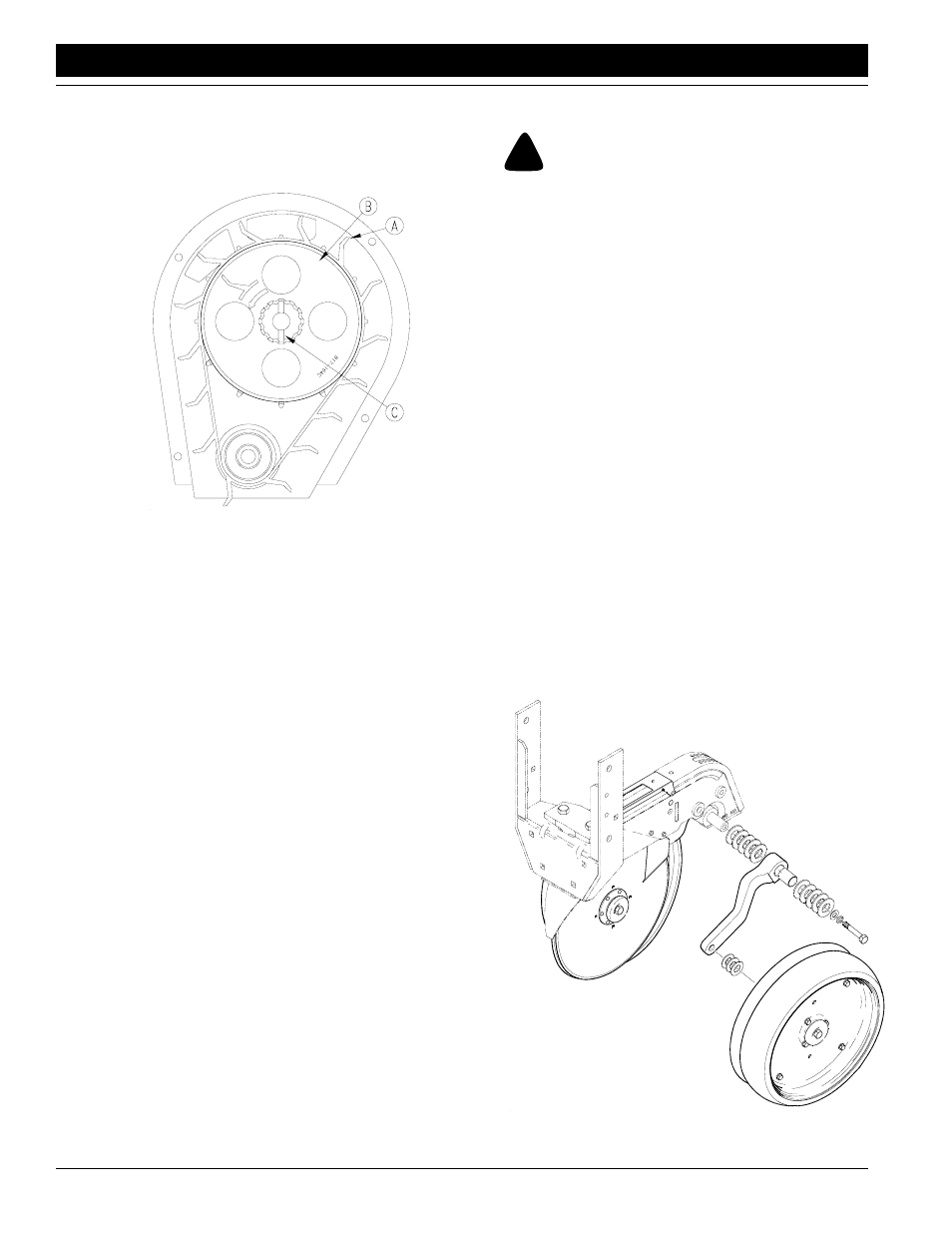

IMPORTANT: See Figure 7-6 if belt is replaced. Be certain

paddles (A) are oriented as shown. Belt drive wheel (B)

may be removed by removing spring pins (C).

Finger Meter Belt Orientation

Figure 7-6

15049

3.

Reassemble in the reverse order.

Spreader and Scraper

The spreader and scraper between the disks will periodi-

cally need replacing. These components scrape dirt off

the disks and protect the seed tube.

To inspect or replace the spreader or scraper do as fol-

lows:

1.

Remove the side gauge wheel and the arm from the

row unit.

2.

Remove the disk blade. Be careful, disks wear very

sharp!

3.

Remove both of the 1/4" bolts holding the scraper and

spreader.

4.

If the sides of the seed tube are worn, replace the

scraper and spreader.

5.

Install the scraper and spreader with 1/4" bolts.

Torque the bolts to the correct values as listed in the

Torque Values Chart in “Section 10 Appendix” on

page

62.

6.

Install the disk and torque the bolt to the correct value

as listed in Torque Values Chart in “Section 10 Ap-

pendix” on page

7.

Install the gauge wheel according to directions under

the Gauge Wheels heading below.

Disk

!

CAUTION!

Disk blades wear very sharp. Handle with care.

As the disks on the row unit wear, removal of shims may

be required to maintain contact point. To remove disk do

as follows:

1.

Remove side gauge wheels and arm from the row

unit.

2.

Remove 3/4" bolts retaining the disks.

3.

Measure disk diameter, if disk measures 14 1/2" or

less replace disk.

4.

If contact is to be increase, move shims from behind

disk to outside disks. This will increase the contact be-

tween the disks.

5.

Install disks and tighten 3/4" bolts to torque values in

Specification Section.

6.

Install gauge wheels and arms according to directions

in this section.

Gauge Wheels

Periodically check gauge tires to be sure there is contact

or a 1/16" gap between the tires and disks.

For installation or adjustments proceed as follows:

1.

Remove the 1/2" bolt holding arm on to the shank.

2.

If tire needs to be closer to disk, move an appropriate

amount of shims from inside of arm to outside, see

Figure 7-7. Each shim is 0.050 thick.

Gauge Arm, Spindle, and Shims

Figure 7-7

12354