Fasteners, Finger pickup meter – Great Plains PT8030 V1012 Operator Manual User Manual

Page 48

46

Section 7 Maintenance and Lubrication

10/10/12

PT6030 and PT8030 Pull-Type Planter 401-032M

Great Plains Mfg., Inc.

Fasteners

When working on the planter torque all bolts, screws, and

nuts to the correct values listed in the Torque Values Chart

in “Section 10 Appendix” on page

62. Check latches

and other fasteners on the planter to prevent failures in the

field.

Finger Pickup Meter

Inspect and repair the finger pickup meter by removing the

2 bolts holding the meter to the hopper. Remove the 3

bolts on the meter baffle to gain access to the finger mech-

anism.

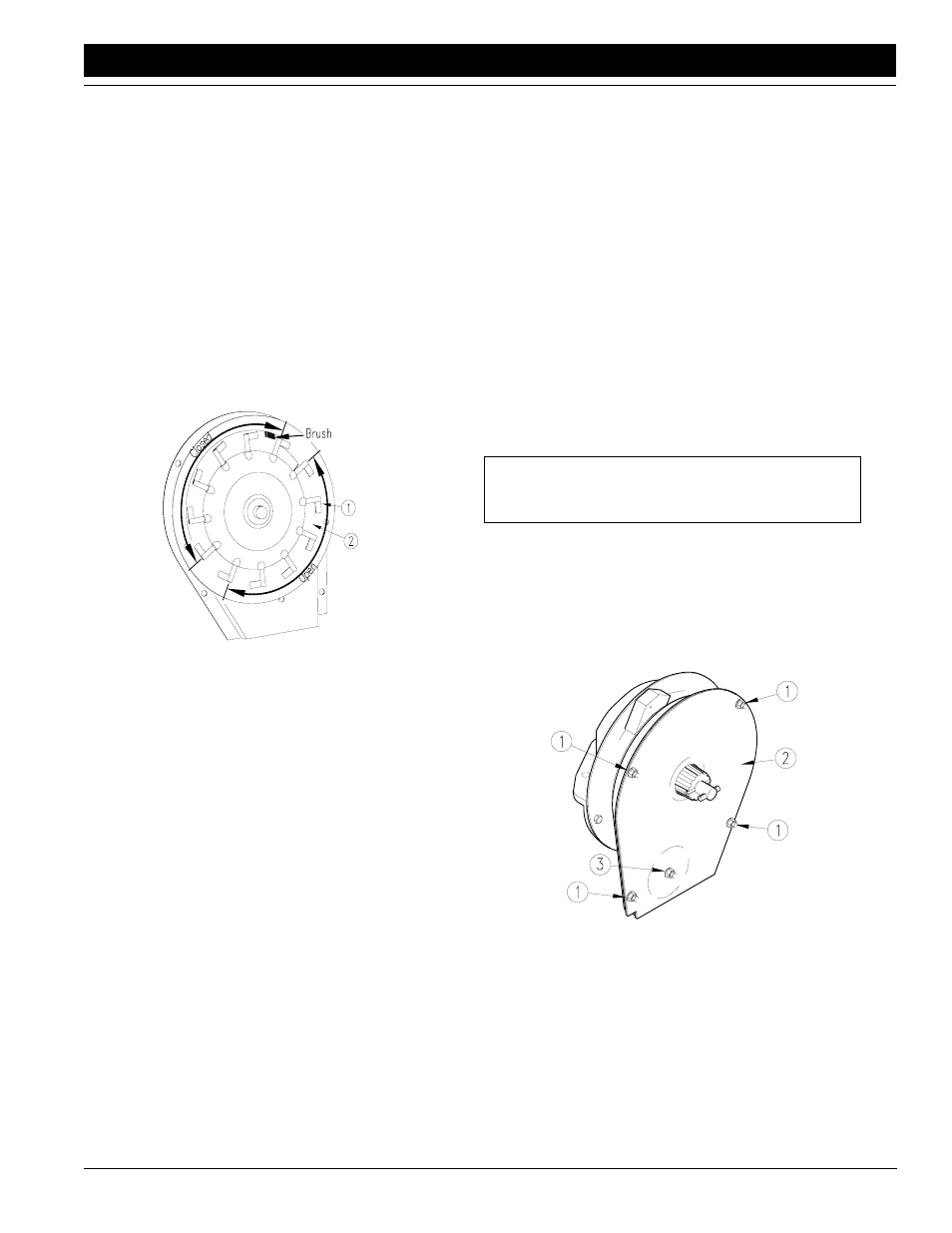

Rotate the meter input shaft by hand to check the fingers.

The fingers should be against the carrier plate in the area

shown closed and raised in the area shown open in Figure

7-4.

Finger Raised/Location of Brush

Figure 7-4

12353

Inspect the brush for wear. The brush should cover at least

1/2 of the finger pickup tab. Replace every 100 acres of

row operation, see Figure 7-4 for location.

Chaff and debris can build-up in the meter preventing

proper functioning of the fingers. Clean every 50 hours of

operation.

To clean the corn meter:

1.

Remove the cotter pin, lock nut, and adjusting nut

from the shaft.

2.

Lift the finger assembly off the shaft and clean.

3.

Replace worn fingers and springs by lifting the finger

out of the slot. Average life expectancy of these parts

should be 250-300 acres of row operation. When fin-

gers are replaced, the open end of the spring loop

should be toward the inside of the finger housing.

4.

Inspect the indentations in the carrier plate for wear.

Replace the carrier plate when wear to the plate be-

comes excessive or the seeding accuracy will be af-

fected.

5.

Reassemble the meter in reverse order. Be sure the

fingers are installed correctly so the finger housing is

flush with the carrier plate. If the finger housing is not

flush with the carrier plate, make sure that the projec-

tion on the cam is in the notch on the bearing housing.

The meter will not function properly if the projection is

not in the notch.

6.

With the finger assembly against the plate, tighten the

adjusting nut until it is snug. Then turn an additional 1/

3 turn. Turn the meter by hand making certain that the

meter is not over tightened. Proper meter resistance

would be 22-25 in/lbs of torque applied at the meter in-

put shaft.

7.

Install the cage nut and the cotter pin.

8.

Install the baffle and attach the meter to the hopper.

Note: Check tightness of the adjusting nut on the

meter after the first day and periodically thereafter.

Check the belt on the meter periodically.

Use these steps:

1.

Remove the 4 bolts (#1) located on the belt housing,

the bolt holding the belt roller and the belt housing

cover (#2). See Figure 7-5.

Finger Meter Belt Removal

Figure 7-5

14966

2.

Inspect or replace the seed belt.