2 to 1 drive reduction, Contact drive wheel spring adjustment, Tire scraper (optional) – Great Plains PT8030 V1012 Operator Manual User Manual

Page 18: Ridge planting

16

Section 2 Planter Operation

10/10/12

PT6030 and PT8030 Pull-Type Planter 401-032M

Great Plains Mfg., Inc.

2 to 1 Drive Reduction

2 to 1 Drive Reduction

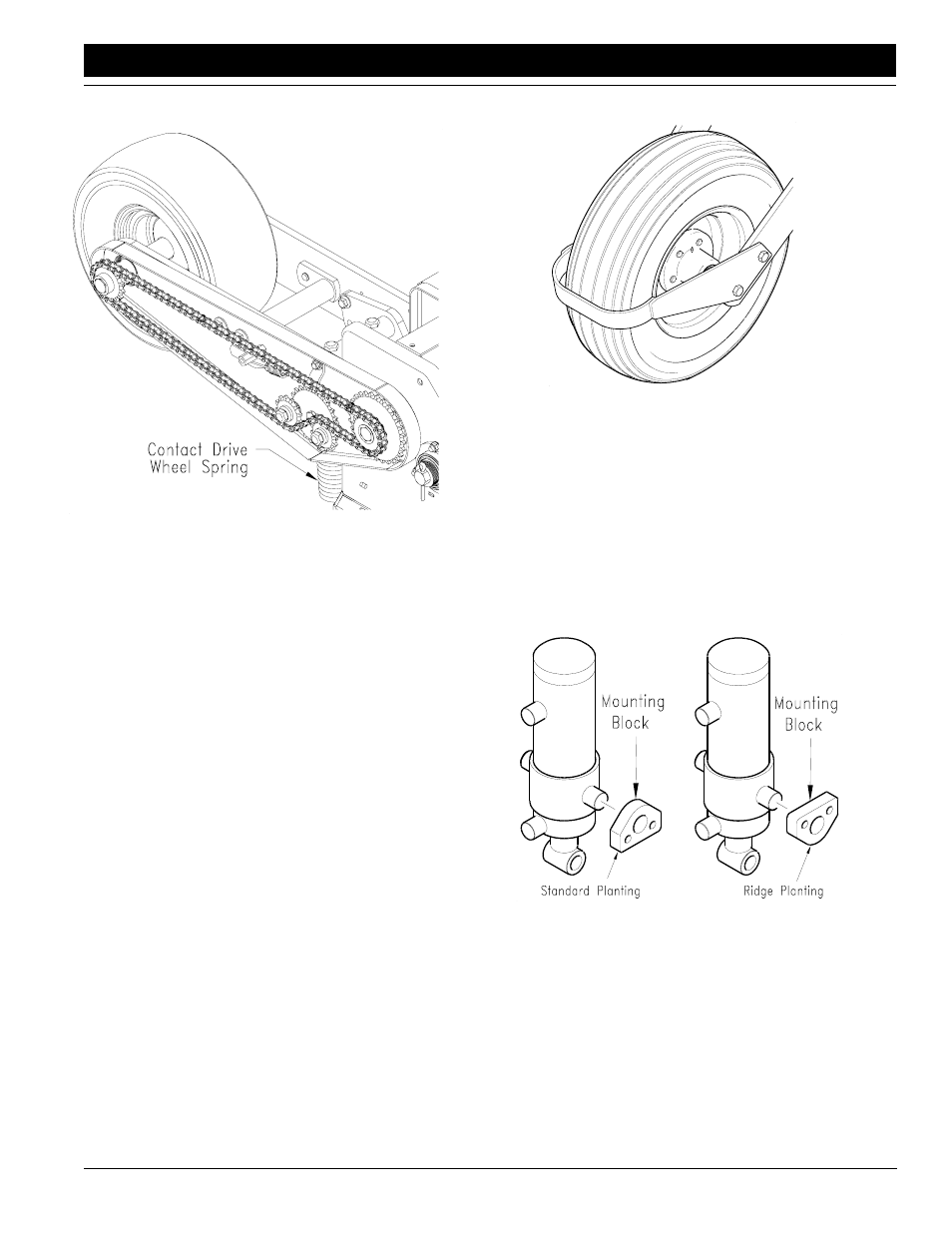

Figure 2-5

15058

The 15/28 tooth drive sprocket located on the inner side of

the contact drive wheel assembly will give you a 2 to 1

drive reduction, and will reduce the planter transmission

speed to reduce planting rates by approximately 1/2.

IMPORTANT: After each sprocket combination adjust-

ment, make a field check to be sure you are planting at the

desired rate.

Contact Drive Wheel Spring

Adjustment

There are two down pressure springs, see Figure 2-5, on

each contact drive wheel. The down pressure is factory

preset and should need no further adjustment.

Tire Scraper (Optional)

Some soil types may require the use of the optional tire

scraper. The scraper prevents an excess of mud from

building up on lift tire that may hamper the contact drive

tire. Adjust the scraper so it does not contact the tire. See

Figure 2-7.

Tire Scraper

Figure 2-7

15027

Ridge Planting

Refer to Figure 2-8:

Lowering the wheel for ridge planting is accomplished by

inverting the cylinder mounting blocks.

To invert, first block under the frame to remove weight from

tires, remove the four 5/8” cap screws. Invert mounting

blocks and install cap screws. Torque per specifications,

see “Section 10 Appendix” on page

62.

Ridge Planting Adjustment

Figure 2-8

14958