Marker hydraulics, General notes, Marker transporting – Great Plains PT8030 V1012 Operator Manual User Manual

Page 19: Liquid fertilizer attachment, Squeeze pump, Pump mounting and hose arrangement, Warning, Danger

17

Section 2 Planter Operation

PT6030 and PT8030 Pull-Type Planter 401-032M

10/10/12

Great Plains Mfg., Inc.

General Notes

•

If both markers are required down at the same time run

one marker down, momentarily start to raise it, reverse

the hydraulic lever and lower the opposite marker. Hold-

ing the lever down then will force both markers down.

If the markers are down they can both be raised simul-

taneously but they can only be lowered one at a time al-

ternating from one side to the other.

•

When oil is cold, hydraulics operate slowly. Make sure

all adjustments are made with warm oil.

•

On a tractor where the oil flow cannot be controlled, the

rate of flow of oil from the tractor may be greater than the

rate at which the marker cylinder can accept it. The trac-

tor hydraulic control lever will have to be held until the

cylinder reaches the end of its stroke. This occurs most

often on tractors with an open center hydraulic system.

On tractors with a closed center hydraulic system, the

tractor’ s hydraulic flow control can be set so the tractor’s

detent will function properly.

Marker Transporting

Always transport the marker with it folded in the flat fold

position.

Liquid Fertilizer Attachment

!

WARNING!

Agricultural chemicals can be dangerous if not selected and

handled with care. Always read and follow directions supplied

by the chemical manufacturer.

Squeeze Pump

Specifications:

Maximum output per hose @ 125 rpm

5/16 Diameter hose-.58 GPM

1/2 Diameter hose-1.4 GPM

Maximum speed - 125 RPM

Maximum pressure - 5 PSI

Horsepower required per hose

5/16 Diameter hose - 0.03 HP

1/2 Diameter hose - 0.05 HP

Pump Mounting and Hose Arrangement

The pump should always be mounted even with or lower

than the fertilizer tank and for accurate metering, the

speed should not exceed 125 RPM.

An important consideration for efficient operation of the

pump is the hose arrangement. If fewer than the standard

number of hoses are to be used, that is, using 4 or 5 hoses

on a 6 hose pump or 10 hoses on a 12 hose pump, the re-

duction in the number of hoses may be made by:

1.

Removing the hoses from near the center of the intake

manifold and capping the intake ports.

Marker Hydraulics

!

DANGER!

Never allow anyone near the planter when cycling the markers.

Excessive travel speed of the markers can be dangerous and/or

damage the marker assembly.The flow controls should be prop-

erly adjusted before the marker assembly is first put into use.

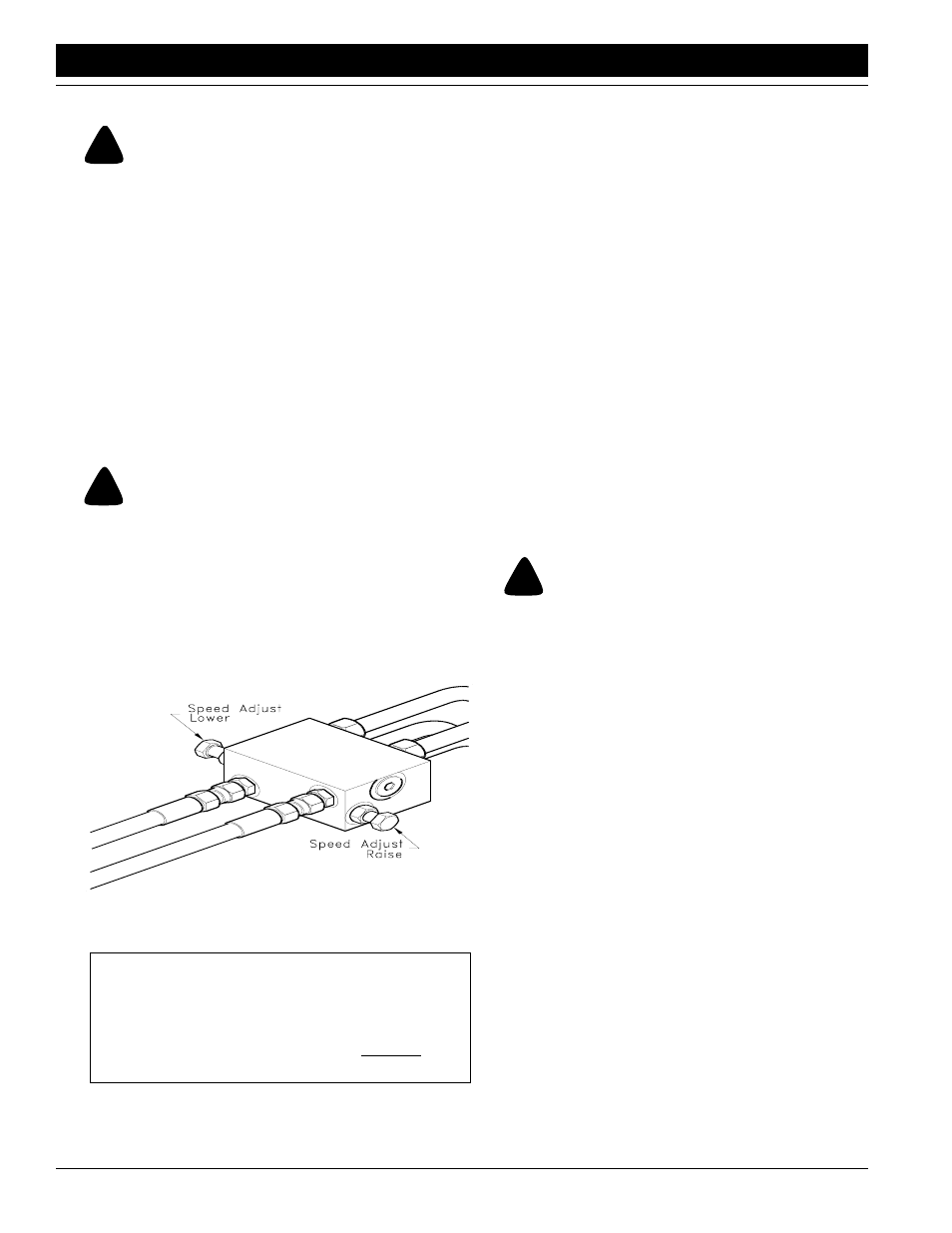

The marker hydraulic system is equipped with needle

valves to control how fast each marker operates. The nee-

dle valves are built into the sequence valve body. There

are two hex adjustment heads, one for controlling marker

speed up and one for controlling marker speed down. To

adjust the speed of each marker, loosen jam nut, screw

the needle valve clockwise to adjust the marker speed to a

low setting. Fold the marker up and down a few times and

recheck for pinching and kinking of hoses. With the tractor

engine at an operating rpm, adjust the needle valve to limit

the marker to a safe operating speed. Excessive folding

speeds can cause marker damage.

!

WARNING!

Escaping Fluid under pressure can have sufficient force to pen-

etrate the skin. Check all hydraulic lines and houses before ap-

plying pressure. Fluid escaping from a very small hole can be

almost invisible. Use paper or cardboard, not body parts, to

check for suspected leaks. If injured, seek medical assistance

form a doctor that is familiar with this type of injury. Foreign

fluids in the tissue must be surgically removed within a few

hours or gangrene will result.

Flow Control Raise/Lower

Figure 2-9

15029

NOTE: JIC fittings do not require high torque. JIC and

O-Ring fittings do not require sealant. Always use liq-

uid pipe sealant when adding or replacing pipe

thread fittings. To avoid possible danger of cracking

hydraulic fittings from over tightening, DO NOT use

plastic sealant tape.