Marker disk adjustments, Disk angle, Direction of cut – Great Plains PT8030 V1012 Operator Manual User Manual

Page 25: Meter drive adjustments, Check for vertical alignment, Section 4 adjustments

23

Section 4 Adjustments

PT6030 and PT8030 Pull-Type Planter 401-032M

10/10/12

Great Plains Mfg., Inc.

Section 4

Adjustments

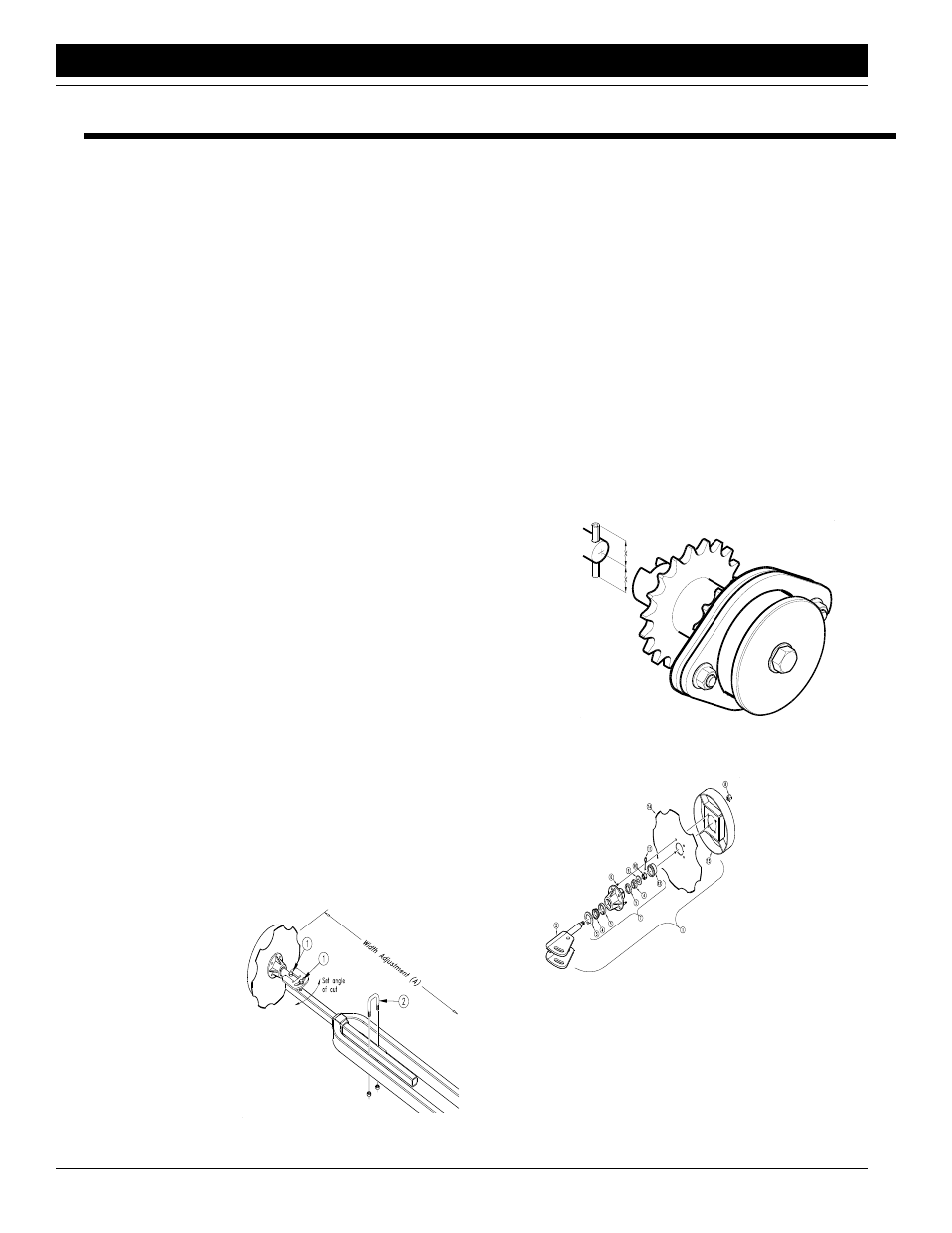

Marker Disk Adjustments

The aggressiveness and the mark left by the disk may be

changed by two methods:

1.

Disk Angle

To change the angle of cut, loosen the two bolts (1),

rotate the disk assembly and retighten.

2.

Direction of Cut

The disk may be mounted to throw dirt either in or out

which will give different marks in different soil condi-

tions. To change the direction of cut:

a.

Reverse the blade and depth band by remounting

the four lug bolts on the disk hub.

b.

Reverse the angle of the assemble by removing

the adjustment bolts (2) and turning the spindle

assembly one half turn. Reinstall and tighten all

bolts.

Marker width adjustments are made by loosening the

marker tube u-bolt #(2) and sliding it in or out to the de-

sired width and by tightening the u-bolt.

Dimension (A) is measured from the center line of the

planting unit to the marker disk.

This are approximate dimensions and should be checked

in the field.

For 6-row wide, 36 inch rows, A = 126 inches.

For 6-row wide, 38 inch rows, A = 133 inches.

For 8-row narrow, 30 inch rows, A = 135 inches.

After adjusting marker, tighten u-bolt.

Marker Disk Adjustments

Figure 4-1

14963

Meter Drive Adjustments

The alignment between the meter clutch and the input

shaft is important. If there is misalignment the meter will

not function properly. Excessive wear and damage can

also occur to the meter housings. When replacing the

meter the vertical and horizontal alignment should be

checked.

Check for Vertical Alignment

Refer to Figure 4-2:

1.

Latch the appropriate hopper into place on the sup-

port.

2.

The roll pin in the end of meter input shaft should be

centered (equal distances of the roll pin should pro-

trude from both sides of the shaft).

3.

Rotate the input shaft so that the roll pin is vertical.

4.

Rotate the drive coupler so that the slots are vertical.

5.

Release the clutch to engage the drive coupler with

the input shaft.

Vertical Alignment

Figure 4-2

12417

If the alignment is correct the coupler will engage with the

shaft freely and the roll pin will extend equally on each side

of the coupler. Disengage the clutch and check the hori-

zontal alignment.