Section 7 maintenance and lubrication, Install cylinder stops, Ratchet drive (8 row only) – Great Plains PT8030 V1012 Operator Manual User Manual

Page 47: Section 7 maintenance, Caution

45

Section 7 Maintenance and Lubrication

PT6030 and PT8030 Pull-Type Planter 401-032M

10/10/12

Great Plains Mfg., Inc.

Section 7

Maintenance and Lubrication

Install Cylinder Stops

!

CAUTION!

Always install cylinder stops when working around or near

planter.

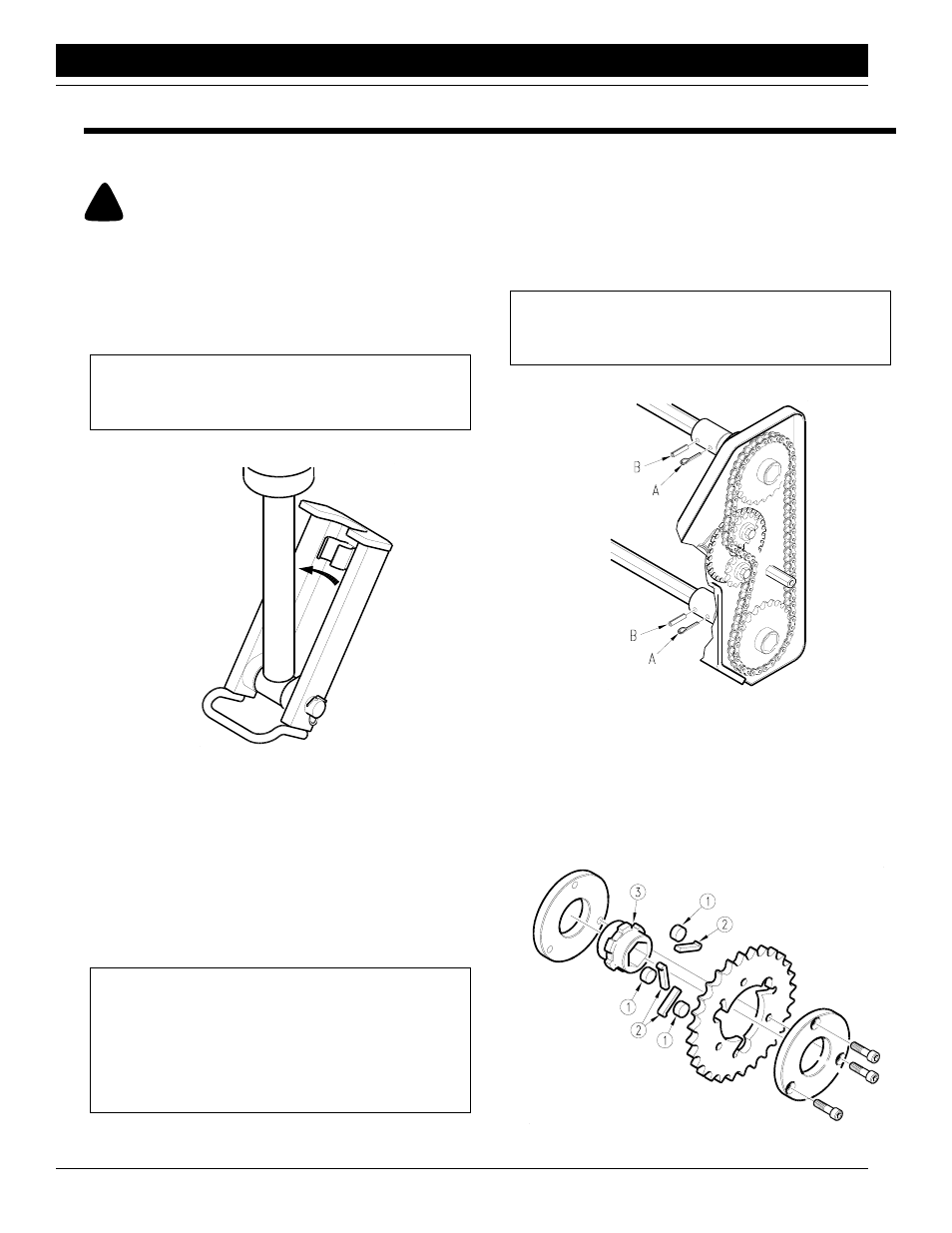

Refer to Figure 7-1:

Raise planter to transport position with tractor remote cyl-

inder operating lever. Pivot cylinder stop into position on

wheel module cylinder rods. Lower to stop.

NOTE: Cylinder stops are provided for added safety

when performing normal maintenance and adjust-

ments with the planter raised.

Cylinder Stop

Figure 7-1

15042

Replacing Drill Shaft Cotter Pins and

Countershaft Shear Pins

Refer to Figure 7-2:

The cotter shear pins (A), which connect the drill shaft to

the transmission and shear pins (B) which connect coun-

tershaft to transmission, will shear when an excessive

load is put on the drill shaft.

NOTE: If drill shaft binds due to misalignment, loosen

bolts on drill shaft bearings on planting units. Make

certain shaft turns freely and tighten bolts.

If countershaft binds due to misalignment, loosen

bolts on transmission bearings. Make certain shaft

turns freely, then tighten bolts.

Infrequent or improper lubrication causes “binding” of

moving parts within the planter. This “binding” will cause

the cotter shear pins to shear, thus preventing breakage of

planter parts.

If either cotter pin shears, turn the drill shaft by hand to lo-

cate where the binding is occurring. When the drill shaft

can be turned freely by hand, replace the cotter pin.

NOTE: Replace the cotter shear pins only with cotter

shear pins of the same size. Do not replace with oth-

er type pins.

Transmission Cotter Pins & Shear Pins

Figure 7-2

15046

Ratchet Drive (8 Row Only)

Refer to Figure 7-3:

The ratchet assembly must operate freely and the springs

(#1) must bring the dogs (#2) back against the ratchet.

Repack with grease annually.

15177

Ratchet Drive

Figure 7-3