Closing wheel alignment, Closing wheel offset, Closing disk adjustments – Great Plains PT8030 V1012 Operator Manual User Manual

Page 28: Closing disk tube shield

26

Section 4 Adjustments

10/10/12

PT6030 and PT8030 Pull-Type Planter 401-032M

Great Plains Mfg., Inc.

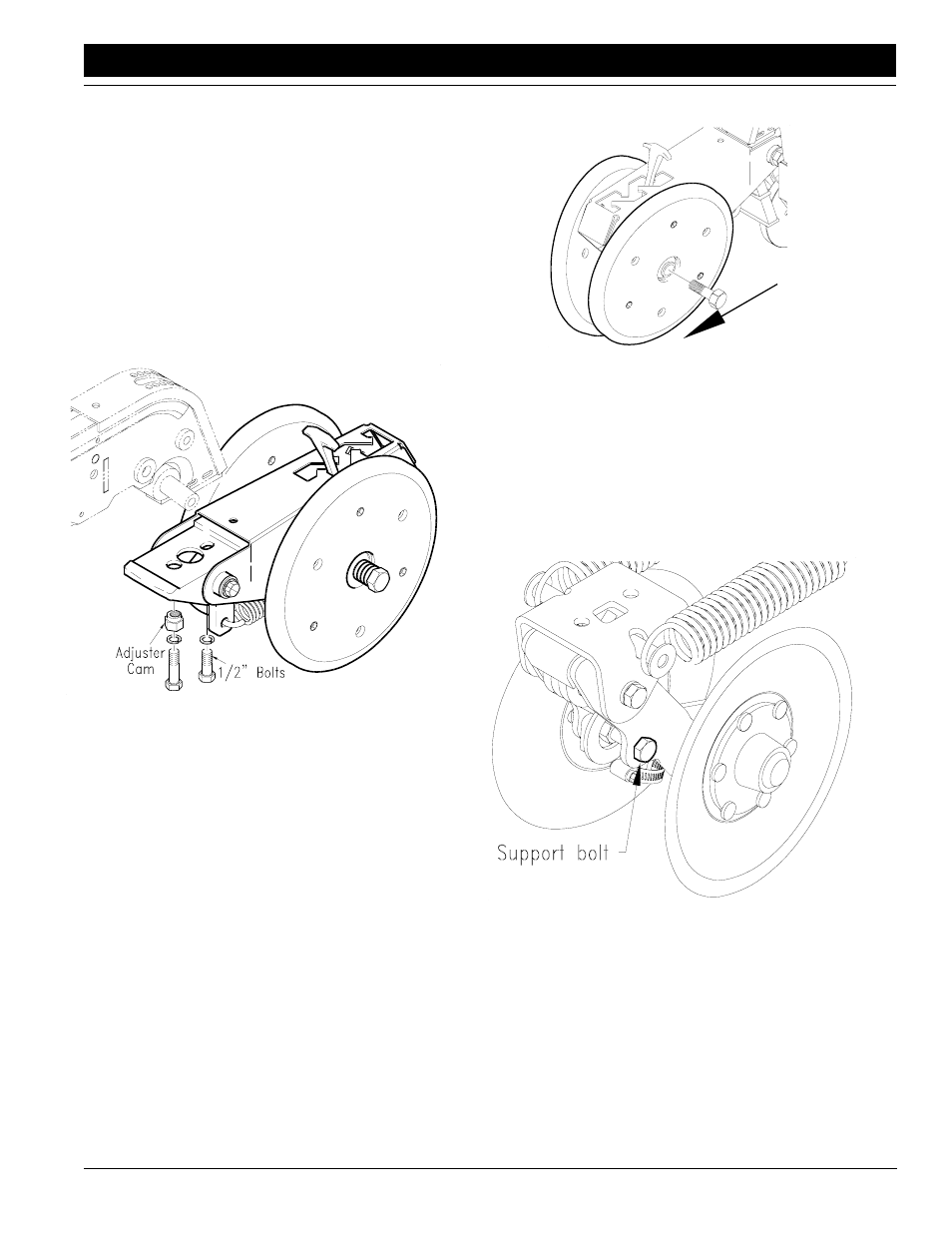

Closing Wheel Alignment

Refer to Figure 4-9:

If one closing wheel is running in the seed trench or the

wheels are not centered over the seed trench, adjust the

closing wheels as follows:

1.

Raise the planter slightly to remove weight from the

closing wheels.

2.

Loosen the two 1/2" bolts.

3.

Turn the press wheel adjuster left or right to center the

wheels over the seed trench.

Tighten the 1/2" bolts to the correct torque values in the

Torque Value Chart in “Section 10 Appendix” on

page

62.

Closing Wheel Alignment

Figure 4-9

12418

Closing Wheel Offset

The 1x12 wheels can be offset to help prevent trash from

plugging the closing wheels. If the closing wheels are not

offset, the wheels should be located in the front holes of

the press wheel arm.

To offset the wheels, do as follows:

1.

Raise planter slightly to remove weight on the closing

wheels.

2.

Remove the 3/4” bolt holding the wheel, see

Figure 4-10.

3.

Move the wheel to the rear hole and attach with the 3/

4" bolt. Tighten the bolt to the correct torque value list-

ed in the Torque Value Chart in “Section 10 Appen-

dix” on page

62.

Closing Wheel & Offset

Figure 4-10

12347

Closing Disk Adjustments

The closing disk options consists of two disks and a

6 1/2 x 12 press wheel. The disk down pressure can be ad-

justed to provide closing of the seed trench.

To adjust the down pressure, ratchet the spring cam to the

next cam height by turning the head of the support bolt

clockwise. Refer to Figure 4-11.

Closing Disk & Tube Holes

Figure 4-11

14913

Closing Disk Tube Shield

To prevent clogging in insecticide hoses:

1.

Clamp closing disk tube shield to closing disk.

2.

Insert insecticide hose (#1) inside the closing disk

tube shield (#2) as shown in Figure 4-12. When unit is

picked up the insecticide hose should be about 1/4”

above the bottom of the shield.