Bleeding hydraulics, Bleeding lift hydraulics – Great Plains CTA4000 Predelivery Manual User Manual

Page 20

16

CTA4000 & CTA4000HD

Great Plains Manufacturing, Inc.

160-037Q

2013-08-21

Bleeding Hydraulics

To function properly, the hydraulics must be free of air. If

hydraulics have not been bled, they will operate with

jerky, uneven motions and could cause wings to drop

rapidly during folding or unfolding. During initial

implement setup complete the following procedures.

Escaping fluid under pressure can penetrate skin, causing

serious injury. Avoid the hazard by relieving pressure before

disconnecting or “cracking” hydraulic lines. Use a piece of

paper or cardboard, NOT BODY PARTS, to check for leaks.

Wear protective gloves and safety glasses or goggles when

working with hydraulic systems. If an accident occurs, seek

immediate medical attention from a physician familiar with

this type of injury.

Bleed only at a JIC (Joint Industry Conference, 37

° flare) or

NPT (National Pipe Thread, tapered thread) fittings, and never

at ORB (O-Ring Boss) fittings.

Bleeding Lift Hydraulics

1.

Check hydraulic fluid level in tractor reservoir and fill

to proper level. Filling a completely empty lift cylinder

set requires about 2 gallons of oil.

Refer to Figure 14

2.

Set valve levers for Field operation.

Refer to Figure 15

3.

With implement still unfolded, and fold cylinder rod

ends

still disconnected, place a support

under

the cylinder end so extending rods will not contact

anything.

Note: Although the Fold cylinder valve handle is set to

Field, Fold cylinders may still be activated by the

Weight Transfer circuit.

4.

Jack up and support implement frame high enough

so opener cylinders can be fully extended. Use a

jack set rated for the weight of the implement (see

Appendix of Operator’s Manual).

5.

Fully extend opener-lift cylinders.

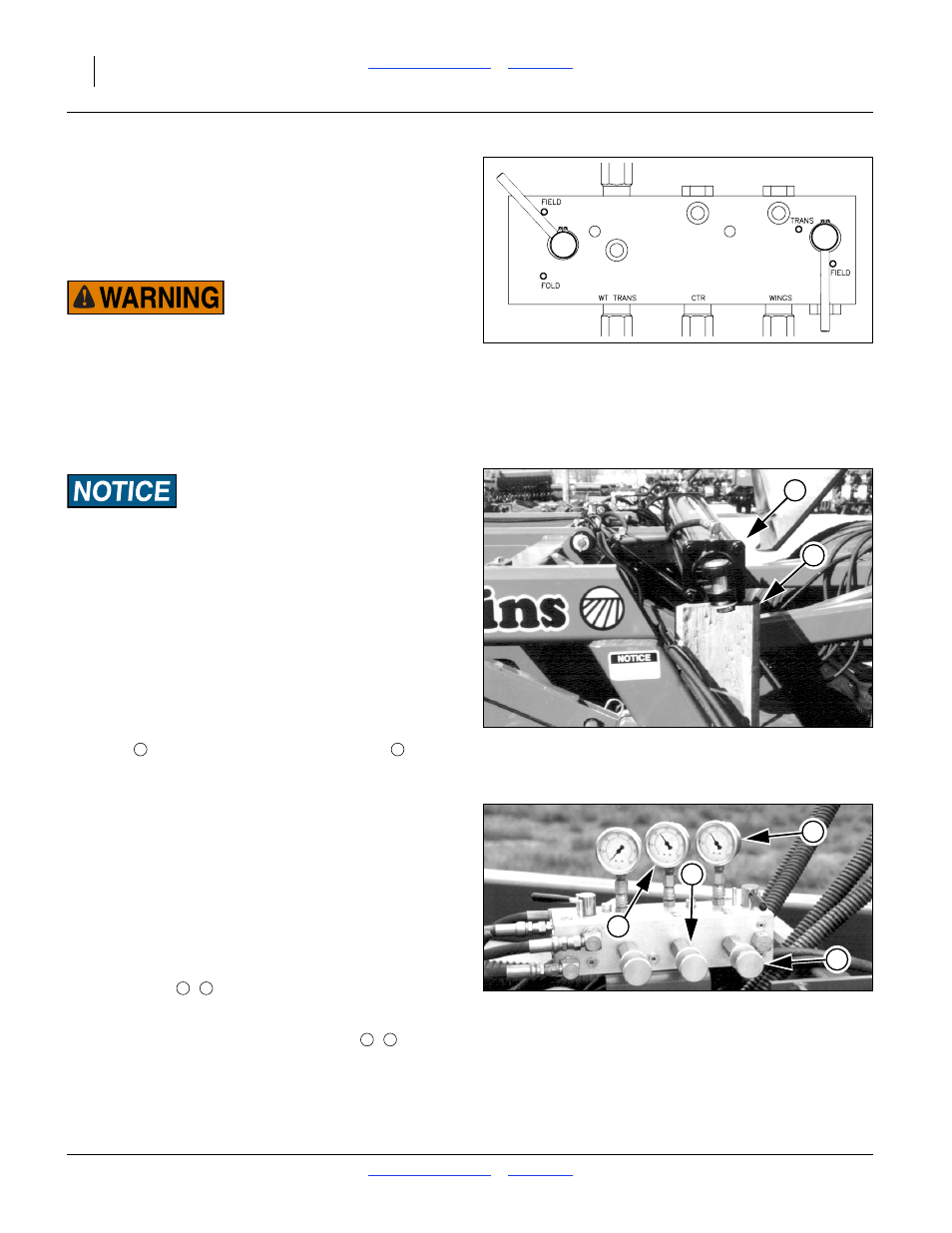

Refer to Figure 16

6.

Turn knobs

,

on pressure-control valves

completely counterclockwise, then turn them back

far enough (about three clockwise turns) to build up

at least 1000 psi pressure per gauges

,

.

Figure 14

Levers for Lift Bleed

26372

2

1

Figure 15

Fold Cylinder Supported

16432

1

2

4

5

6

3

Figure 16

Adjusting for Lift Bleed

26380

3

4

5

6