SARGENT NB-WD8600 Concealed Vertical Rod Exit Device for Wood Doors User Manual

Page 2

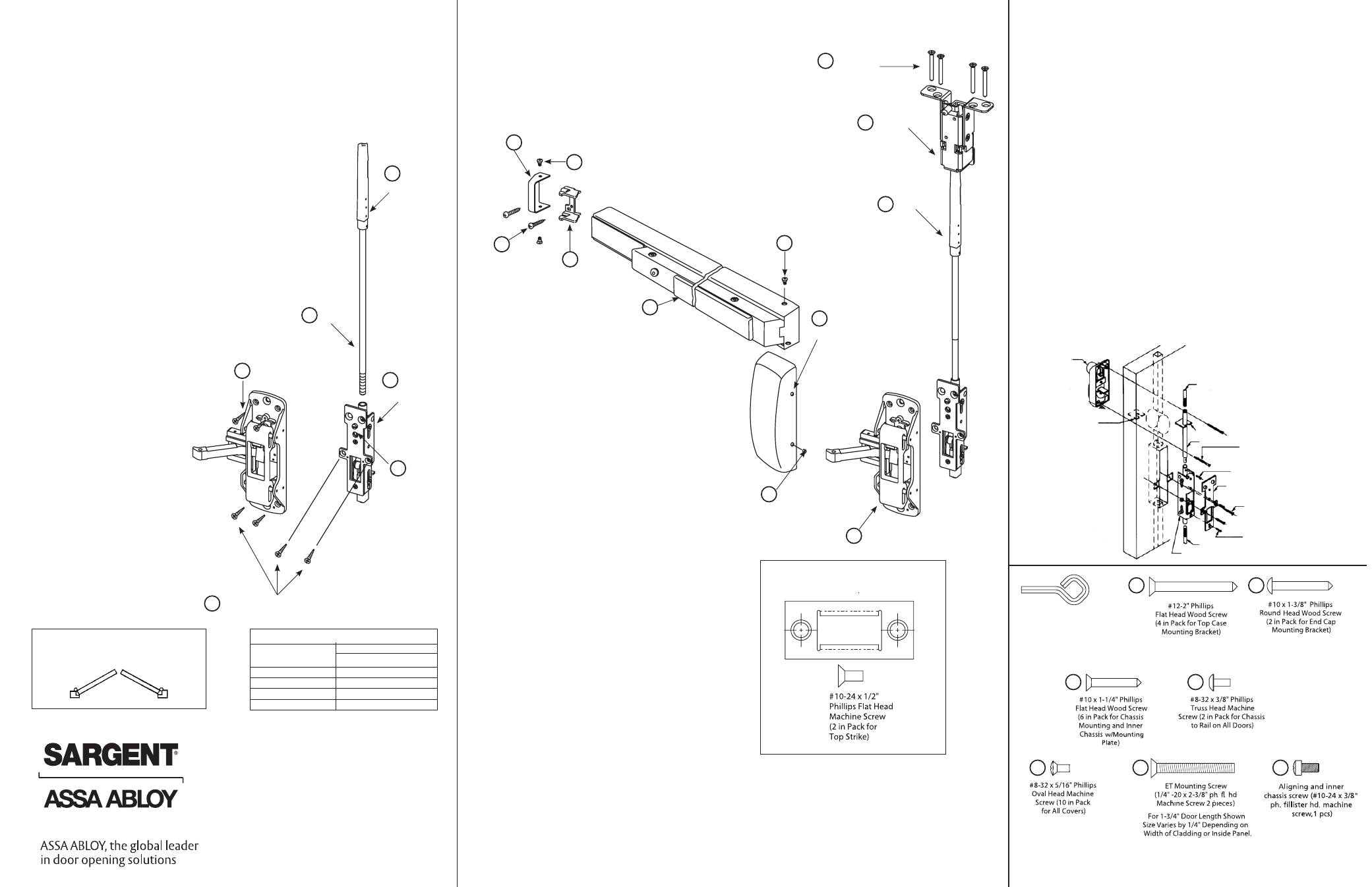

Note: For WD100 Series Auxiliary Control, the

following steps are required prior to Step #2 of this

instruction sheet

STEP 1

Through the cut out for the inner chassis, slide the extension into door

with reduced diameter down.

STEP 2

Insert inner chassis in the door cutout and insert reduced end of exten-

sion in top threaded bushing on inner chassis. Attach with #8-32 x 7/16”

Phillips oval head machine screw.

STEP 3

From the outside of door through the cutout, install plate onto extension.

STEP 4

Attach inner chassis mounting plate to inner chassis with (2) #6-32 x 1/2”

flat head screws.

STEP 5

Attach 100 Series Auxiliary Control to door with (2) #10-24 x 2-1/8” oval

head machine screws.

WD100

Series

Auxiliary

Control

Ref. install

plate thru hole

for auxiliary

control

Top rod

#10 x 11/4” Wood screw

(2 required)

#8-32 x 7/16” Machine screw

(1 required)

Inner chassis

Inside

of door

Plate

extension

Manual dogging key

(not used with 12-) To operate:

depress push rail, insert hex key

(or cylinder key when used) and

turn clockwise. Not furnished

with fire rated devices.

Instructions for SARGENT WD8600, 12-WD8600,

NB-WD8600 and NB-12-WB 8600

with 100 Series Auxiliary Controls

See other side for 700 Series ET Control

Bottom rod

#6-32 x 1/2” Machine screw

(2 required)

Inner chassis mounting plate

#10-24 x 2-1/8” Machine screw

(2 required)

Outside

of door

Instructions for Installing SARGENT NB-WD8600 &

12-NB-WD8600 Series Concealed Vertical Rod Exit Device

FOR ASSISTANCE, CALL SARGENT AT 1-800-727-5477.

Verify the correct exit device is being installed on the correct door.

Function, finish and size should all be verified.

Note: Before removing door from hinges, determine the gap between

top of door and frame.

This information is needed for step #5. Remove door from the frame.

1) Pilot drill as required during installation.

Note: If 100 Series Auxiliary Control is being used, it

must be installed at this point. See installation

instructions at the far right.

2) Install FILLISTER HEAD screw (HH), inner chassis,

as shown

3) Attach inner chassis w/mounting plate (A) to door with

(2) screws (CC)

4) From top of door, screw top rod (B) into inner

chassis (A).

Note: If 700 Series ET Control is being used, it must

be installed at this point. See installation instructions

on the other side.

5) Position chassis (D) over fillister

head screw (HH) and attach to door with

(4) screws (CC). Do not tighten yet.

Use chassis (D) to retract top rod (B)

to adjust bolt projection.

6) Adjusting top bolt (F) projection

1) 1/8” gap or less between door

top and frame. Rotate bolt to

make even with top of door.

2) 1/8” gap or greater. Bolt to

extend above door equal to gap

minus 1/8”.

Chassis

#10 x 1-1/4”

Wood screws

For additional

information, contact

SARGENT

at 1-800-727-5477

D

CC

Inner

chassis

w/mounting

plate

A

Top rod

B

F

Chassis

D

Top

bolt

F

Top

chassis

E

#12-2”

Flat head

wood screws

AA

7) Slide top chassis (E) over top bolt (F). Secure to top of door

with (6) screws (AA).

8) Install door into frame using the hinges.

9) Slide rail assembly (J) onto chassis (D).

10) Align holes for screw (EE).

11) Level rail.

12) Locate and mark holes for mounting plate (K).

13) Attach mounting plate (K) to secure rail

assembly (J) to door with (2) screws (BB).

14) Tighten screws (CC) to verify that chassis (D)

is secured to door.

15) Check the following for proper operation:

a) Push rail in to retract bolt.

b) Bolt stays retracted (hold back).

c) Bolt releases when door closes. Button inside.

d) Bolt engagement with strike 1/4”- 5/16”.

16) Position cover (L) onto chassis (D) and attach with

(4) screws (FF).

17) Secure end cap (M) to mounting plate (K)

with (2) screws (FF).

18) Secure rail assembly (J) to chassis (D) with

(2) screws (EE).

19) For NB-WD8600 & 12-NB-WD8600, 650 top

strike is attached to frame with two

#10-24 x 1/2” machine screws (supplied).

Inside

LEFT HAND

REVERSE

BEVEL

RIGHT HAND

REVERSE

BEVEL

THIS EXIT DEVICE IS HANDED

CHECK HAND OF DEVICE AGAINST APPLICATION

Outside

Fillister head

screw

Truss head screw

#8-32 x 3/8”

Oval head screw

#8-32 x 5/16”

End cap

Round head

screw

#10-32 x 3/4”

Mounting

plate

Rail assembly

Cover

M

EE

L

FF

BB

K

J

Oval head

screw

#8-32 x 5/16”

FF

Information for Cutting Rails

Rail Sizes

Door Widths

Max Min

E

32” 24”

F

36” 33”

J

42” 37”

G

48” 43”

Top bolt

AA

BB

CC

EE

FF

GG

650 TOP STRIKE PACK

Note: Bolt & rod must be

retracted while adjusting bolt

projection. Use chassis (D) to

retract top bolt (F) and

top rod (B)

Note: To be fire rated, 12-NB-WD8600 Series Exit

Devices require installation of thermal pin.

HH

HH

© SARGENT Manufacturing Company

A3937H 3/12

© SARGENT Manufacturing Company

A3937H 3/12

© SARGENT Manufacturing Company

A3937H 3/12