Pump assembly, Danger, Caution – Viking Pump TSM635.3: Q-QS Universal Mag Drive User Manual

Page 8

SECTION TSM

635.3

ISSUE

C

PAGE 8 OF 13

DANGER !

Follow these directions exactly to avoid injury

to self or damage to the pumping unit. Be

careful to keep the inner and outer magnets at

least (1) foot apart until step 17. Do not engage

the magnets in any other fashion.

CAUTIoN !

Do not place fingers onto the front of pump

mounting flange. Align the canister into bore

of the bracket and gently slide it in. When the

magnets start to engage, the unit will finish

engagement on its own very rapidly unless the

5/8” x 6” capscrew is properly used. Make sure

fingers are not on the front of the pump. See

Sequence in Figure 18.

DANGER!

Be certain that the driving means (motor, tur-

bine, engine, etc.) has been “locked out” or

made non-operational so that it cannot be

started while work is being done on pump.

PUMP ASSEMBLY

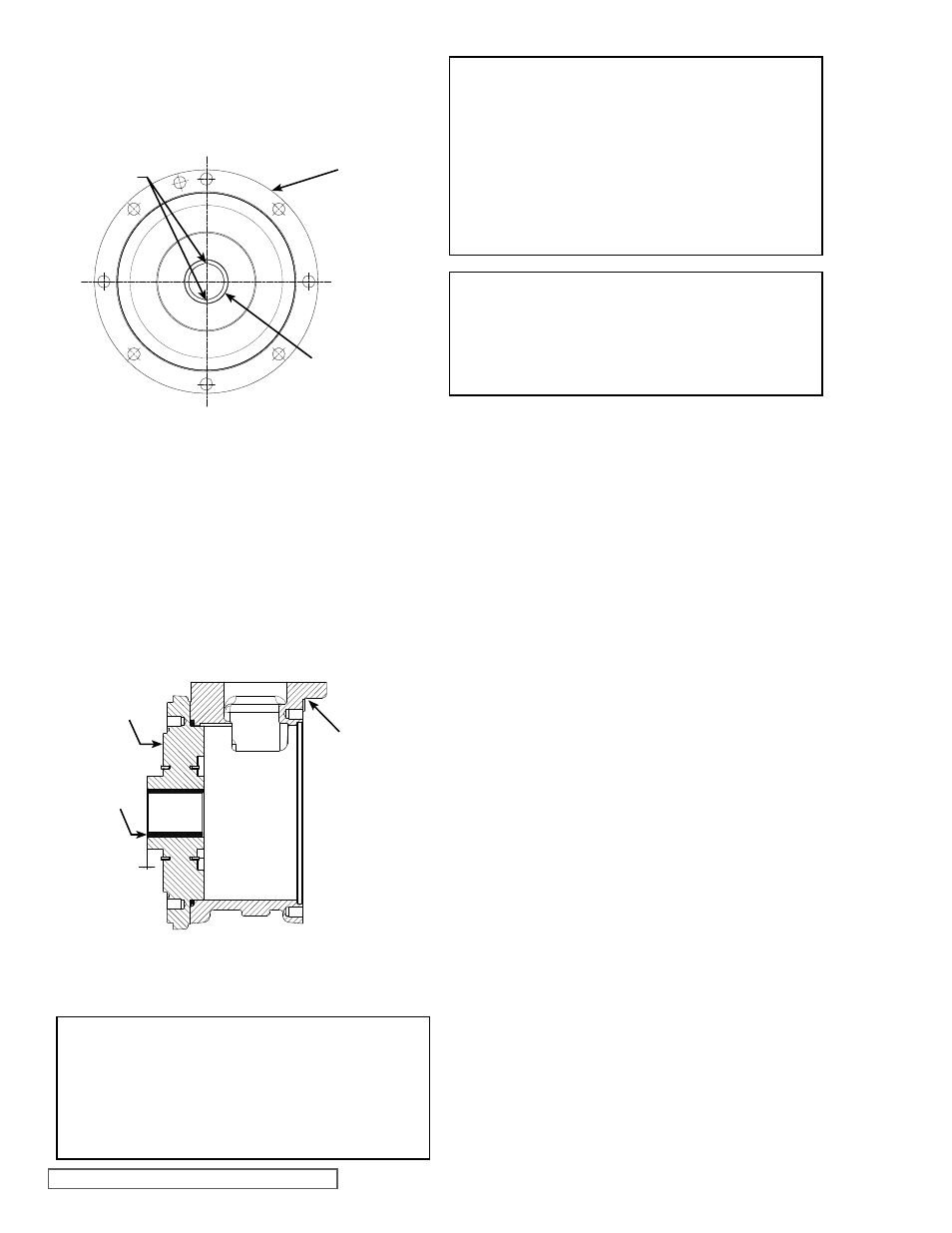

FIGURE 14

ADAPToR PLATE BUSHING PoSITIoN

ADAPToR

PLATE

BUSHING

CASING

INCH MM

.000 0.000

-.005 -0.127

NoTE: Some steps require a second person for ease

of assembly.

Use a suitable lubricant compatible with the fluid being

handled when reassembling the pump.

Inspect all parts, especially drilled holes in the casing (for

draining) to make sure they are not plugged. Replace any

worn parts, remove any burrs and clean all parts before

assembling the pump. Use a non-magnetic surface to

assemble the pump.

1. If the adaptor plate O-ring on the casing side needs to

be replaced, apply a lubricant to the O-ring and place it

onto the casing side of the adaptor plate. If the O-ring

is PTFE (derivative) encapsulated, follow these special

instructions.

Do not attempt to reuse this type of O-ring if it has been

removed. Immerse a new O-ring in boiling water for

a few minutes. Remove it from the water and stretch

out the O-ring. This ensures it will fit into the plate or

groove without forcing the O-ring over a sharp edge.

Run hot water over the O-ring until it shrinks down tight.

Hot water makes the PTFE pliable and allows the inner

elastomer to pull the PTFE back to the original size. Dry

it with compressed air.

2. Position the adaptor plate so the adaptor plate groove

aligns to groove in the casing bore at suction port, see

Figure 15. Carefully slide the adaptor plate into the

bracket side of the casing. Use care to prevent cutting

the O-ring with the edge of the adaptor plate or casing.

Secure into position by tightening the eight capscrews.

3. Apply lubricant to the ID of the adaptor plate bushing.

Clean the rotor and shaft so it is free of dirt, grit and

other debris. Remove burrs around the keyway and

shoulder of the shaft.

4. Apply a light oil to the first set of thrust washers on

the side of the thrust washer that will touch the rotor

or adaptor plate. Place the thrust washer that does not

have a groove onto the shaft so that the blind holes in

the thrust washer will line up with the drive pins on the

back of the rotor. Place the thrust washer with a groove

onto the adaptor plate so that the groove in the thrust

washer will line up with the grooves in the adaptor

plate, see

Figure 15.

LUBE

GRooVES

BUSHING

CANISTER

FIGURE 13

CANISTER:

Figure 13 shows the proper orientation of the canister

bushing after installation. Bushing should be flush with or

up to 0.010” below bushing hub face. Be certain canister is

properly supported.

BUSHINGS:

Installing bushings may require a special fixture to ensure

proper positioning. Improper location may result in a pump

with excessive slip, pre-mature wear or requiring a large

number of shims.

The additional precautions listed below must be followed for

installation:

1. An arbor press must be used for the installation.

2. Be certain the bushing is started straight.

3. Do not stop the pressing operation until the bushing is in

the proper position; starting and stopping will result in a

cracked bushing.

4. After installation, check the bushing for cracks.