Pump disassembly, Warning – Viking Pump TSM635.3: Q-QS Universal Mag Drive User Manual

Page 5

54

59

65

66

57

46

47

45

44

43

40

63

35

38

39

37

36

60A

60

31

52

51

33

67

25

60A

60

13

62

6

4

1

2

5

3

14

7A

7

8

28

28A

12

27

6

5

58

SECTION TSM

635.3

ISSUE

C

PAGE 5 OF 13

ITEM

NAME oF PART

ITEM

NAME oF PART

ITEM

NAME oF PART

13

Capscrews for Adaptor Plate (8-Req’d)

40

Head and Idler Pin Assembly

57

Inner Magnet Assembly

25

Adaptor Plate Bushing

43

Studs for Head (8-Req’d)

59

Canister

31

Casing

44

Nuts for Head (8-Req’d)

60

Thrust Washer - Rotating (2-Req’d)

33

Adaptor Plate O-Ring

45

Relief Valve Gaskets (2-Req’d)

60A

Thrust Washer - Stationary (2-Req’d)

35

Head O-Ring

46

Capscrews for Relief Valve (8-Req’d)

62

Key for Rotor Shaft

36

Rotor and Shaft Assembly

47

Relief Valve

63

Shims for Head

37

Idler and Bushing Assembly

51

Studs for Flanges (16-Req’d)

65

Canister O-Ring

38

Idler Bushing

52

Nuts for Flanges (16-Req’d)

66

Split Locknut

39

Idler Pin

54

Capscrews for Canister (8-Req’d)

67

Adaptor Plate

ITEM

NAME oF PART

ITEM

NAME oF PART

ITEM

NAME oF PART

1

Locknut

6

Tapered Roller Bearing (2-Req’d)

14

Capscrews for Disassembly (3-Req’d)

2

Lockwasher

7

Bearing Housing

27

Bracket

3

End Cap

7A

Capscrews for Bearing Housing (6-Req’d)

28

Capscrews for Mounting Bracket (2-Req’d)

4

Outer Bearing Spacer

8

Inner Bearing Spacer

28A

Capscrews for Bracket (2-Req’d)

5

Lipseal (2-Req’d)

12

Grease Fitting

58

Outer Magnet Assembly

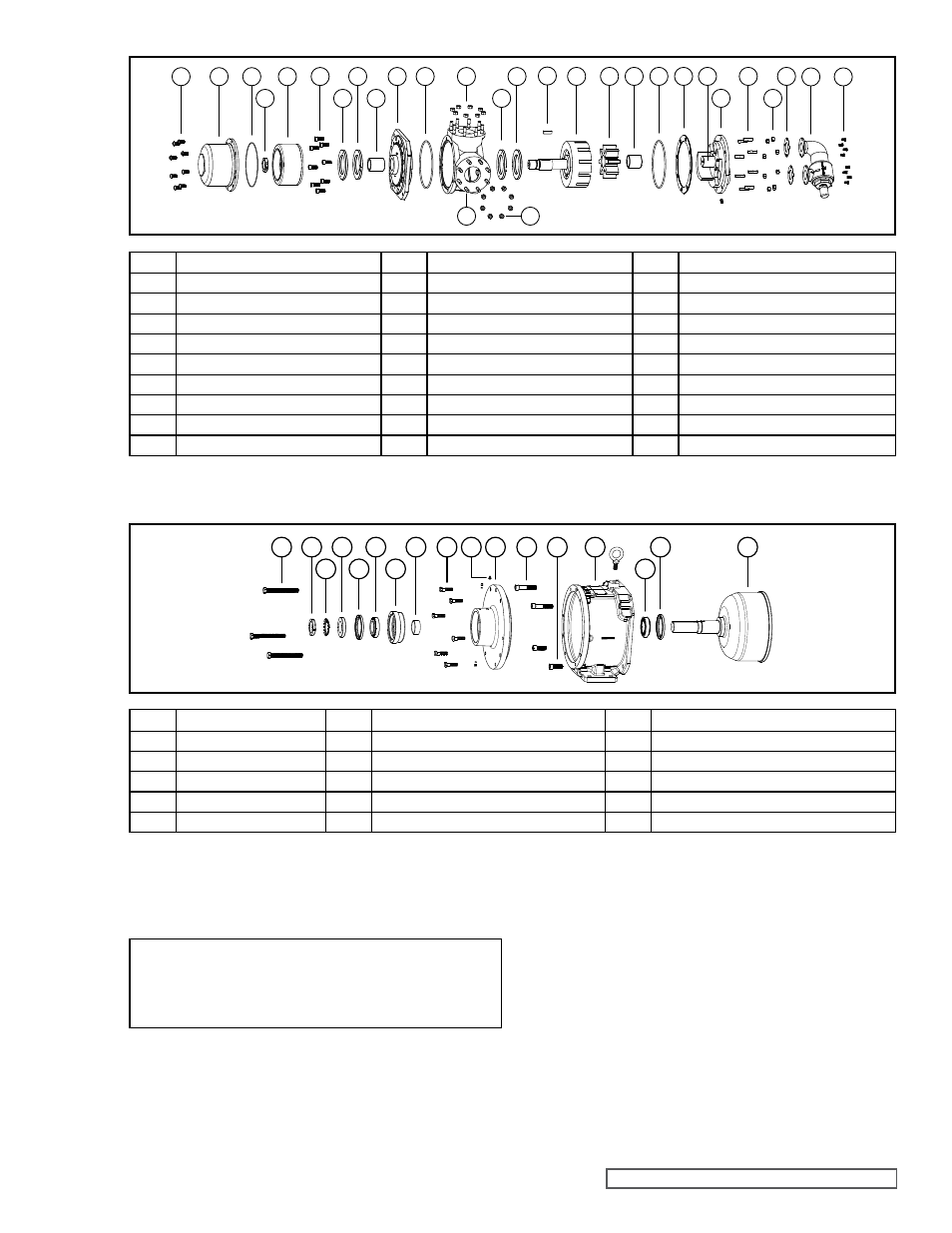

FIGURE 6

ExPLoDED VIEW – UNIVERSAL MAG DRIVE PUMP CANISTER THRoUGH RELIEF VALVE

FIGURE 7

ExPLoDED VIEW – UNIVERSAL MAG DRIVE PUMP BRACKET AND oUTER MAGNET ASSEMBLY

PUMP DISASSEMBLY

WARNING!

Refer to DANGER & CAUTIoN listed on page 2

before proceeding.

NoTE: Some steps require a second person for ease

of disassembly.

1. Drain the liquid being pumped by removing the two

drain plugs (if present). Both are located in the bottom

of the casing. Once the liquid has drained, replace the

plugs.

2. Refer to Figures 6 and 7 for the names of parts.

3. Use a non-magnetic surface to disassemble the pump.

4. Mark the head (40) and casing (31) before disassembly

to insure proper reassembly.

5. To inspect the head and pin assembly (39 and 40) and

idler and bushing assembly (37 and 38), remove the

head nuts (44).

6. Remove the head from the pump. Tilt the top of the

pump head back during removal to prevent the idler

from falling off the idler pin. If the casing was not

drained in Step 1, be careful of the liquid draining out

between the head and casing. Avoid damaging the

head shim set (63) since all shims are required to

maintain end clearance. Inspect the O-ring (35). Do

not remove the O-ring from the plate adaptor / casing