Disassembly / assembly of bearing housing, Installation of bushings, Disassembly – Viking Pump TSM635.3: Q-QS Universal Mag Drive User Manual

Page 7: Assembly, Carbon graphite

SECTION TSM

635.3

ISSUE

C

PAGE 7 OF 13

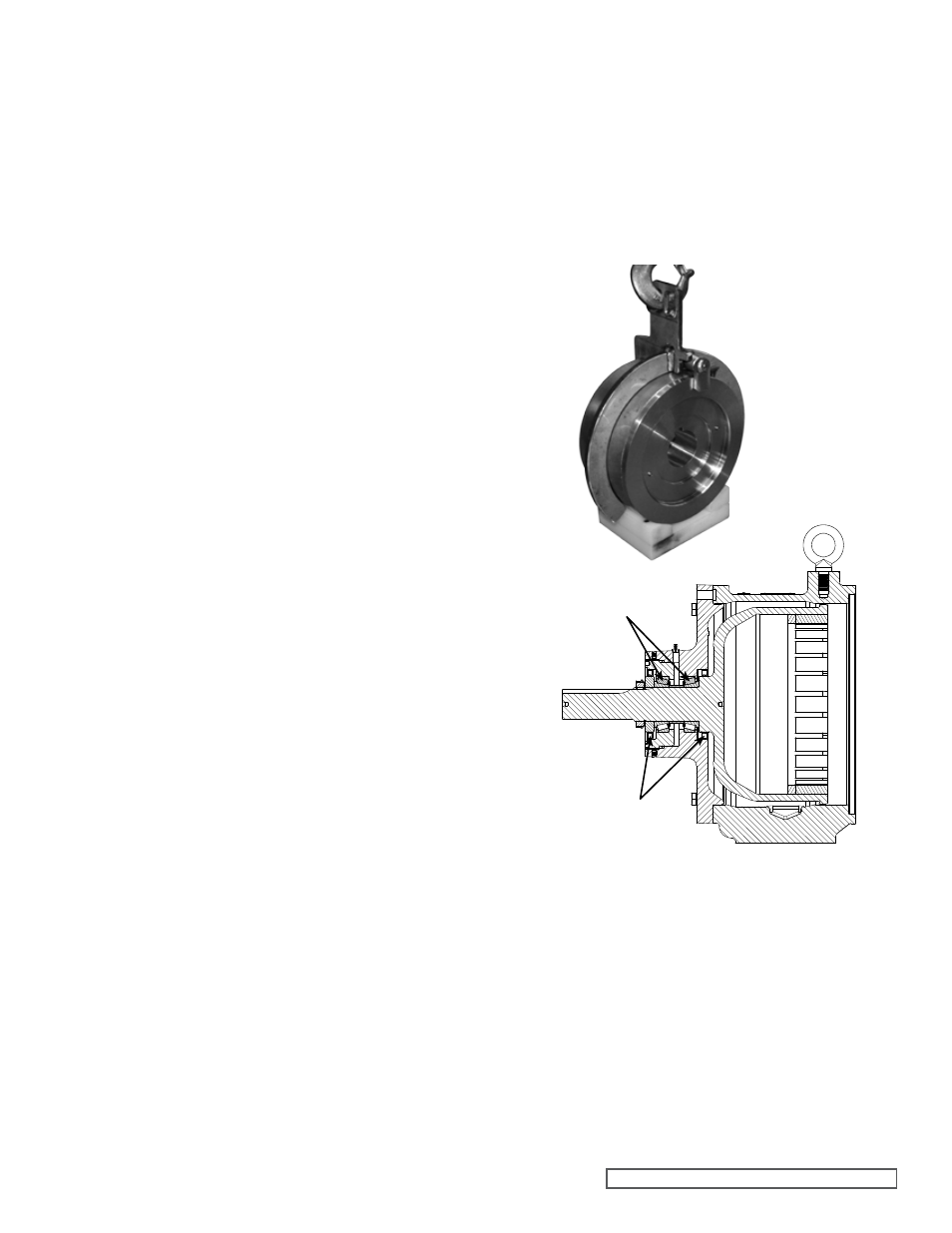

FIGURE 11

DISASSEMBLY / ASSEMBLY oF

BEARING HoUSING

DISASSEMBLY

The bearing carrier assembly features two tapered roller

bearings, two lipseals, and one spacer. If further disassembly

of this unit is required, proceed as follows:

1. Remove locknut (1) and washer (2).

2. Loosen the setscrews holding the end cap (3) in the

bracket. Screw the end cap out of the bracket.

3. Inspect the bearings (6) for wear; replace as needed.

4. Inspect the lipseals (5) for wear; replace as needed. The

lipseals will need to be replaced if removed.

5. If the bearings are worn it is recommended to replace

the entire bearing. Remove the inner bearing spacer

collar (8). Press the inner bearing cup out of the bearing

housing and the outer bearing cup out of the end cap.

The bearings will need to be replaced if the cups are

removed.

ASSEMBLY

1. If the bearing cups were removed, press the cup of the

outer bearing into the end cap. Press the cup of the inner

bearing into the bearing housing.

2. Press the inner lipseal into the bearing housing and

the outer lipseal into the end cap and then lubricate the

lipseals, see

Figure 12 for lipseal and bearing orientation.

3. Screw the end cap into the bearing housing (clockwise)

until it contacts. Do not over-tighten the end cap.

4. Inspect the outer magnet to make sure it has not picked

up any foreign particles, which could damage the pump.

Slide the inner roller bearing onto the shaft, followed by

the inner bearing spacer.

5. Slide the outer magnet assembly into the bearing

housing. Slide the outer roller bearing onto the shaft.

Slide the outer bearing spacer collar onto the shaft and

into the outer lipseal, followed by the lockwasher and locknut.

6. Tighten the locknut to 170-190 ft-lbs of torque and then

bend over the appropriate lockwasher tab.

7. Unscrew the end cap (counterclockwise) by hand until

there is considerable drag on the bearings. Mark the end

cap and bracket in the same spot. Then screw in the end

cap (clockwise) 5/16”, radially from the mark. Tighten the

end cap setscrews.

8. Grease the bracket using the bracket fitting with NLGI #2

grease. Make sure the shaft freely rotates by hand.

FIGURE 12

BRACKET BEARING AND LIPSEAL oRIENTATIoN

TAPERED RoLLER

BEARINGS

LIPSEALS

care that the thrust washer on the rotor does not come

off. Remove the thrust washer from behind the rotor if

worn, cracked or the rotor and shaft is being replaced.

Remove and check the casing side adaptor plate thrust

washer for cracks or wear; replace if necessary.

16. Inspect the adaptor plate bushing (25). If the bushing

needs to be replaced, see

“Installation of Bushings”

on page 7. If the pump is leaking between adaptor plate

and casing (31), remove the socket head capscrews

(13) from the adaptor plate. Slide the adaptor plate out

of the casing.

17. Inspect the O-ring (33). Do not remove the O-ring

from the plate adaptor / casing unless it is damaged,

especially if it is PTFE encapsulated. If a new O-ring is

required, See

“Pump Assembly” on page 8.

18. Inspect the casing for wear, particularly in the area

between the ports. Clean all other parts thoroughly and

examine for wear or damage.

When making major repairs, such as replacing a rotor and

shaft, it is advisable to also install a new head and idler

pin, idler and bushing, and adaptor plate bushing. See

“Installation of Bushings” on page 7.

INSTALLATIoN oF BUSHINGS

CARBoN GRAPHITE

If attempting to install the carbon graphite idler, canister

or adaptor plate bushings, extreme care must be taken

to prevent breaking. Carbon graphite is a brittle material

and easily cracked. If cracked, the bushing will quickly

disintegrate. Using a lubricant on the bushing and mating

part will help facilitate installation.

ADAPTOR PLATE:

The groove in the ID of the bushing should line up with the

groove in the adaptor plate.

Figure 14 on page 8 shows the

proper position of the adaptor plate bushing after installation.