Pump rotation, Adjusting end clearance – Viking Pump TSM635.3: Q-QS Universal Mag Drive User Manual

Page 10

SECTION TSM

635.3

ISSUE

C

PAGE 10 OF 13

PUMP RoTATIoN

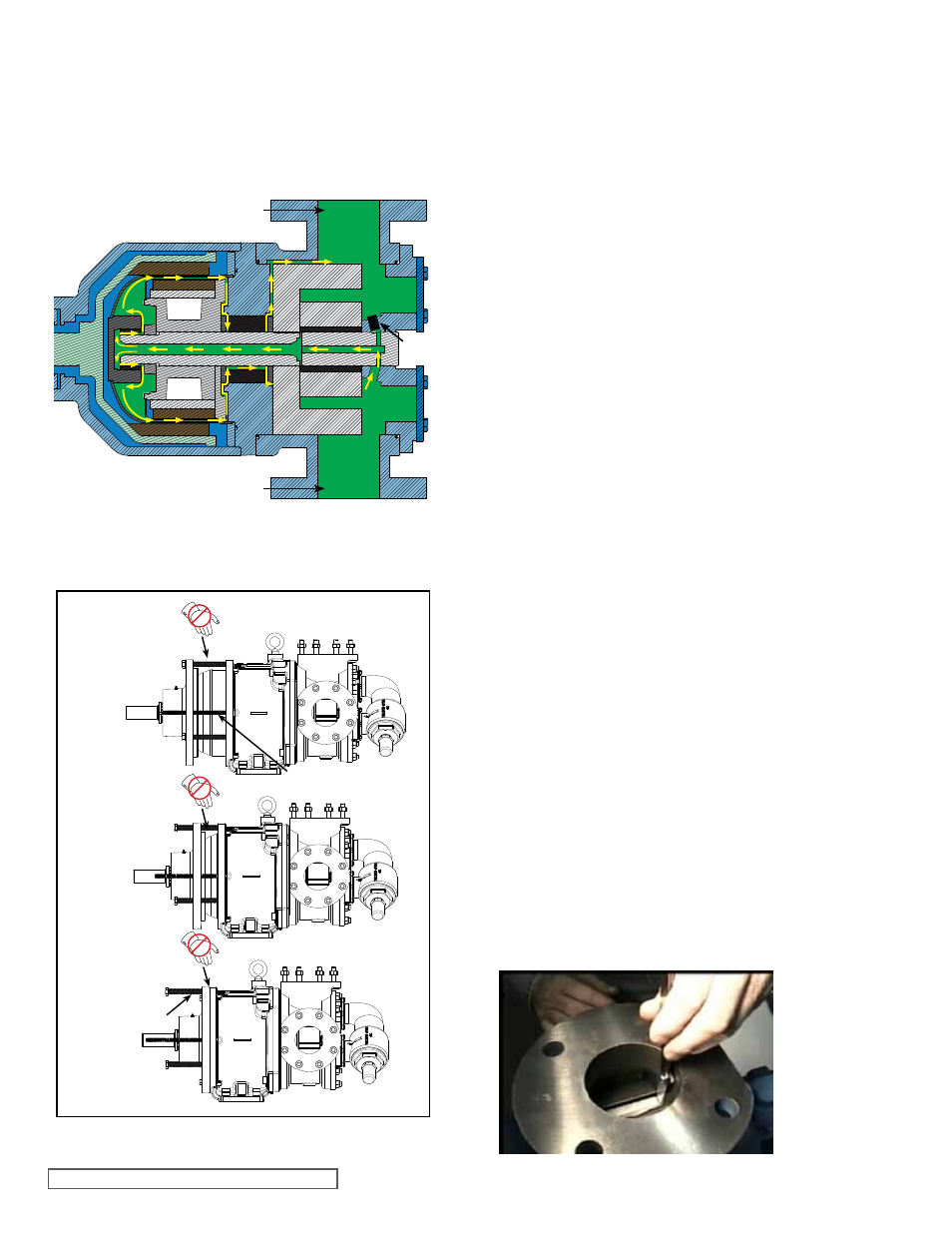

Process fluid is generally fed to the hollow shaft and idler

pin from the discharge side of the pump. Fluid is pushed into

the canister bushing and around the inside of the canister.

Then the fluid flows through the thrust washers and adaptor

plate bushing interface back to the suction side of the pump.

When the pump is operated in the opposite direction, the

fluid flow is reversed, see

Figure 17.

ADJUSTING END CLEARANCE

Standard end clearance of 0.010” is used on sizes Q and

QS. End Clearances are adequate for viscosities up to

2500 SSU / 540 cSt (SAE 40 lube oil at room temperature).

Higher viscosities require additional clearances. As a

general rule, the end clearance is doubled for higher

viscosities. For specific recommendations on end clearance

for high viscosity or for operating temperatures above

225°F (107°C), check with your Viking representative or

consult the factory. Use either of the following procedures

to properly adjust the end clearance when replacing

shims or reassembling the pump.

PROCEDURE A:

After the rotor has been installed and the locknut has been

positioned and retained, insert a feeler gage of the proper

end clearance into the port and between two rotor teeth, see

Figure 19. With the idler on the idler pin, place the head

into the pump casing. With the capscrews tight, the feeler

gage should fit snugly; otherwise shims should be added or

reduced in thickness until the proper clearance is attained.

FIGURE 19 PRoCEDURE A

FIGURE 18

PUMP ASSEMBLY SEQUENCE

Do NoT PLACE

FINGERS HERE

CAPSCREW

Do NoT PLACE

FINGERS HERE

ALL-THREAD RoD

Do NoT PLACE

FINGERS HERE

any foreign particles, which could damage the pump.

Place the canister sleeve onto the canister. Support the

pump with an overhead hoist and fixture while guiding

the canister into the bracket opening. Secure the pump

to the bracket using four socket head capscrews.

16. Inspect the bearing housing bearings and lipseals;

replace if needed. Refer to

“Disassembly / Assembly

of Bearing Housing”, page 7. Inspect the outer

magnet for any steel objects, which may be attached.

Remove any foreign material.

17. Insert three fully threaded 5/8” X 6” hex head capscrews

into the bearing housing until they are fully extended in

front of the bearing housing to control assembling the

pump, see

Figure 18. To keep the bearing housing and

bracket assemblies properly aligned and for additional

safety, it is recommended to use 2 lengths of all-thread

rod (12”) threaded into opposite capscrew locations in

the bracket and slide through the corresponding holes

in the bearing housing.

18. Back the capscrews off, being careful that the end of

the capscrew is positioned in the counterbore hole of

the bracket. Secure the bearing housing to the bracket

with six capscrews.

Make certain that the power supply to the pump is

“Locked-out”. Check that the pump rotates freely by

spinning the motor fan blades or pump shaft.

This figure is for illustrative purposes only.

Actual pump construction and location of ports varies.

SUCTIoN PoRT

DISCHARGE PoRT

PLUG

FIGURE 17

CIRCULATIoN oF LIQUID THRoUGH

UNIVERSAL MAG DRIVE PUMP