Maintenance, Caution – Viking Pump TSM635.3: Q-QS Universal Mag Drive User Manual

Page 3

SECTION TSM

635.3

ISSUE

C

PAGE 3 OF 13

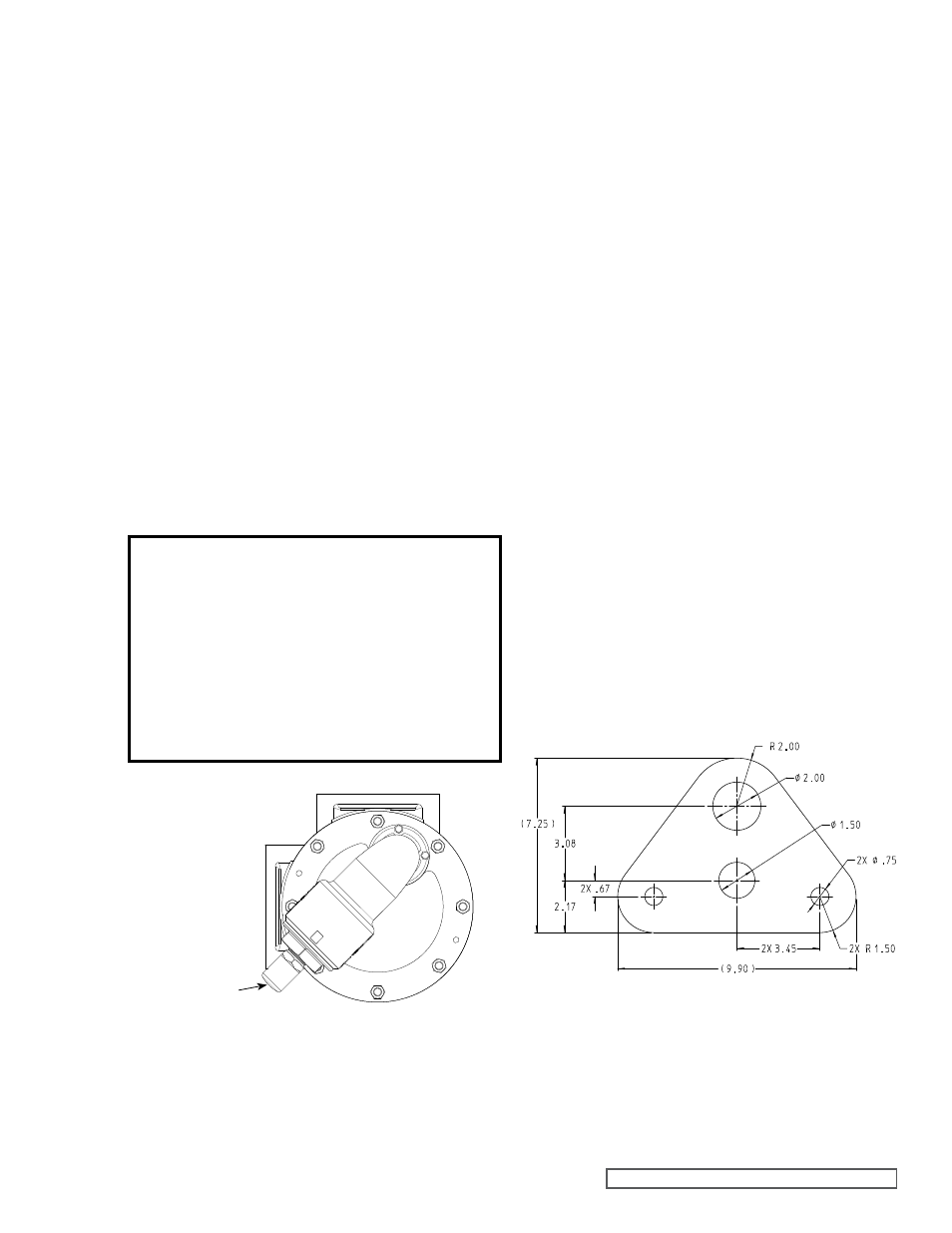

FIGURE 2

RELIEF VALVE PoSITIoN

ROTATION: Viking Mag Drive® pumps are designed to run

in either direction. See

“Pump Rotation”, page 10.

PRESSURE RELIEF VALVES:

1. Viking pumps are positive displacement pumps and

must be provided with some sort of pressure protection.

This may be a relief valve mounted directly on the pump,

an inline pressure relief valve, a torque limiting device

or a rupture disk. Do not rely on decoupling of magnets

for protection from over pressure; this may result in

damage to the magnets, pump, or other equipment.

2. Relief valves are mounted as standard on the casing of

all pumps.

3. If the pump rotation is to be reversed during operation,

pressure protection must be provided on both sides of

the pump.

4. The relief valve adjusting screw cap must always point

towards the suction side of the pump, see

Figure 2.

If the pump rotation is reversed, remove the pressure

relief valve and turn end for end (see

“Pump Rotation”,

page 10).

5. Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure.

For additional information on pressure relief valves, refer to

Technical Service Manual TSM000 and Engineering Service

Bulletin ESB-31.

CAUTIoN !

Rare earth magnets used in couplings have

extremely strong magnetic fields capable of

changing performance or damaging items

such as the following:

Pacemakers

Metal Implants

Watches

Computers & disks

Credit Cards

RELIEF VALVE

ADJUSTING

SCREW CAP

SUCTIoN

DISCHARGE

MAINTENANCE

Series 8124A, 8123A and 8127A pumps are designed

for long, trouble-free service life under a wide variety of

application conditions with a minimum of maintenance. The

points listed below will help provide long service life.

CLEANING PUMP:

Keep the pump as clean as possible. This will facilitate

inspection, adjustment and repair work.

LUBRICATION:

Bracket bearings require external lubrication. This must be

applied slowly with a handgun to lubrication fittings every

500 hours of operation with multi-purpose grease, NLGI # 2.

Do not over-grease. Applications involving very high or low

temperatures will require other types of lubrication. Refer to

ESB-515. Consult factory with specific lubrication questions.

STORAGE:

If the pump is to be stored, drain and pour non-detergent

SAE 30-weight oil (or compatible alternative) into the pump

port. Apply grease to the pump shaft, if accessible. Viking

suggests rotating the pump shaft every 30 days to circulate

the oil in the pump. The pump should be stored in a dry area.

SUGGESTED REPAIR TOOLS:

The following tools are required to properly repair series

8124A, 8123A and 8127A pumps. These tools are in addition

to standard mechanics’ tools such as open-end wrenches,

pliers, screwdrivers, etc. Most of the items can be obtained

from an industrial supply house.

1. Soft face hammer

2. Allen wrench set (SAE)

3. Torque wrench with a locknut socket

4. Two feeler gauge sets

5. Arbor press

6. Brass bar

7. Hook style spanner wrench

8. Canister Sleeve (3-810-025-999-00)

9. Inner Magnet Lift (3-810-026-999-00)

10. Bearing Housing Lift (Figures 3 and 9)

FIGURE 3

BEARING HoUSING LIFT

NoTES:

1. Material must conform to ASTM A36

2. Dimensions are in inches

3. Tolerances are ± .02

4. Thickness is .25