Viking Pump TSM635.3: Q-QS Universal Mag Drive User Manual

Page 6

SECTION TSM

635.3

ISSUE

C

PAGE 6 OF 13

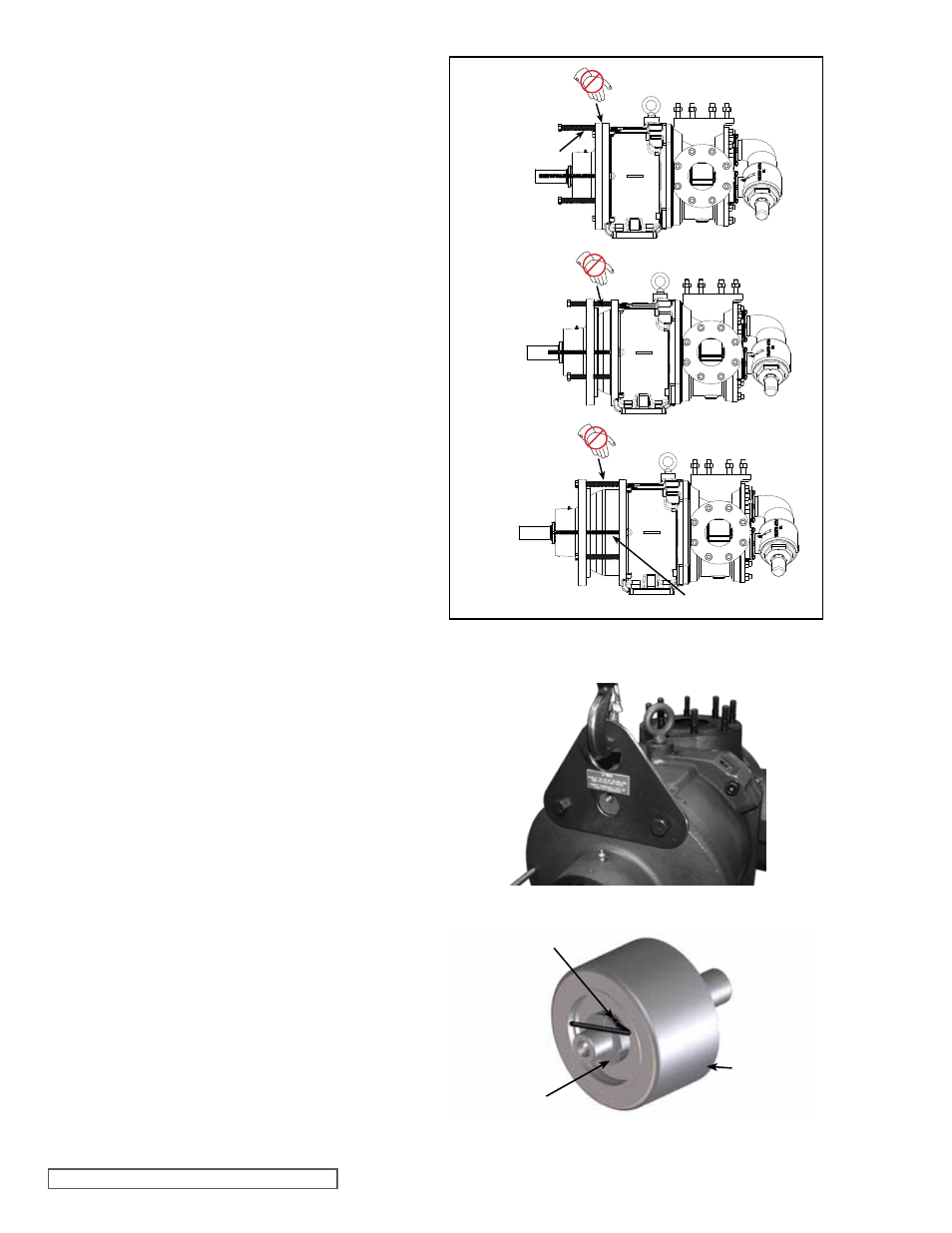

FIGURE 10

INNER MAGNET AND LoCKNUT ASSEMBLY

FIGURE 9

SETSCREW

LoCKNUT

INNER

MAGNET

ASSEMBLY

unless it is damaged, especially if it is PTFE (derivative)

encapsulated. If a new O-ring is required, See

“Pump

Assembly” on page 8.

7. Remove the idler and bushing assembly. Inspect the

idler bushing for wear. If the idler bushing needs to be

replaced, see

“Installation of Bushings” on page 7.

If further disassembly is required, proceed to the next

step.

8. If further disassembly is required, separate the pump

from the motor. Remove the six hex head capscrews

(7A) securing the bearing housing to the bracket.

Support the bearing housing with an overhead hoist

using a tool. See

Figure 9 dimensions for tool on page

3. Do not use tool to lift pump, use eyebolt on bracket.

9. Use the jackscrews (14) in the bearing housing to

separate the inner magnet (57) from the outer magnet

(58), see sequence in

Figure 8. To keep the bearing

housing and bracket assemblies properly aligned

and for additional safety, it is recommended to use 2

lengths of all-thread rod (12”) threaded into opposite

capscrew locations in the bracket and slide through the

corresponding holes in the bearing housing.

10. Slide the outer magnet assembly out of the bracket (27).

Visually inspect the outer magnets. Inspect the magnet

assembly for damage or wear; replace if needed. If

further disassembly of the bearing housing is required,

see

“Disassembly / Assembly of Bearing Housing”,

page 7.

11. Place the canister sleeve (3-810-025-999-00) into the

bracket over the canister (59). Remove the socket

head capscrews (28 & 28A) securing the bracket to the

pump. Support the pump with an overhead hoist and

fixture that is in-line with the center of gravity of the

pump. Slide the pump out of the bracket.

12. Remove the canister sleeve. Remove the socket head

capscrews (54) from the canister. If the canister was

not drained in Step 1, it will contain liquid. Use care

when removing the canister from the pump by pulling

it straight off. Inspect the canister bushing (64) for

wear. If the canister bushing needs to be replaced, see

“Installation of Bushings” on page 7.

13. Inspect the O-ring (65). Do not remove the O-ring from

the plate adaptor (67) / canister unless it is damaged,

especially if it is PTFE encapsulated. If a new O-ring is

required, See

“Pump Assembly” on page 8.

14. Insert a brass bar into the rotor (36) through a port

between two rotor teeth and remove the split locknut

(66), see

Figure 10. Support the inner magnet using

inner magnet lift (3-810-026-999-00).

Do not forget

this is a very strong magnet. Slide the inner magnet

assembly off of the shaft. Make sure the thrust washer

(60) does not fall off the inner magnet assembly. Place

inner magnet on non-magnetic cradle similar to

Figure

11. Inspect the magnet assembly for damage or wear;

replace if needed. If further disassembly is required,

proceed to the next step.

15. Remove the shaft key from the rotor shaft. Remove the

thrust washer (60A) from the adaptor plate if worn or

cracked. The rotor and shaft may now be removed by

tapping on the end of the shaft with a soft face hammer

(If a soft face hammer is not available, a regular

hammer may be used with a piece of hardwood). Take

FIGURE 8

PUMP SEPARATIoN SEQUENCE

Do NoT PLACE

FINGERS HERE

CAPSCREW

Do NoT PLACE

FINGERS HERE

Do NoT PLACE

FINGERS HERE

ALL-THREAD RoD