Disassembly – Viking Pump TSM630.3: N-RS Universal Seal User Manual

Page 5

A

SECTION TSM 630.3

ISSUE

H

PAGE 5 OF 13

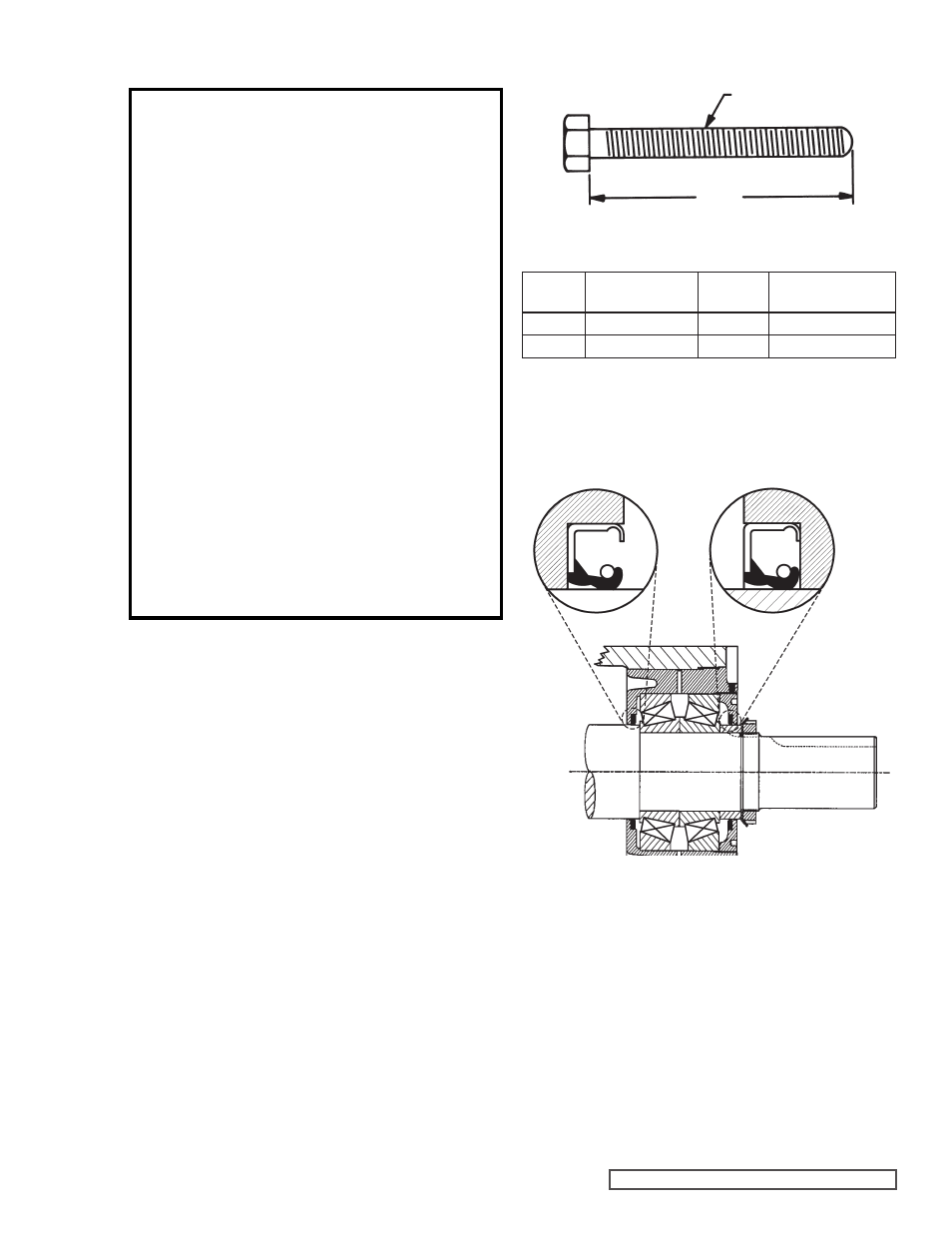

FIGURE 4

FIGURE 5

N-R BEARING HOUSING ASSEMBLY

DISASSEMBLY

DANGER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

1. Mark head and casing before disassembly to insure proper

reassembly. The idler pin, which is offset in pump head,

must be positioned toward and equal distance between

port connections to allow for proper flow of liquid through

the pump.

Remove nuts from head. Jackscrews should be used to

back head away from casing. Proper size and length of

jackscrews for pump size are shown in

Figure 4. The

use of a hoist to support head will facilitate its removal.

Avoid damaging head gasket. Back head slightly away

from casing. Do not allow idler to fall from idler pin.

To prevent this, tilt top of head back when removing.

Remove head from pump. A lifting hook will provide

adequate connection for hoisting head. If a hoist is not

available, cribbing or blocking can be used to support

head. This will eliminate having to lift head into position

when reassembling pump.

If pump is furnished with pressure relief valve, it need

not be removed from head or disassembled at this point;

however, removing relief valve will lessen total weight of

part. Do not use chain or cable around relief valve body

to support head during removal.

Refer to Pressure

Relief Valve Instructions, page 11.

PUMP

SIZE

NO. SCREWS

USED

A

THREAD SIZE

(INCH)

N

2

4.00

0.50” - 13 NC

R & RS

2

4.50

0.63” - 11 NC

THREAD SIZE

MINIMUM LENGTH OF JACK SCREWS