Viking Pump TSM630.3: N-RS Universal Seal User Manual

Page 10

SECTION TSM 630.3

ISSUE

H

PAGE 10 OF 13

When installing carbon graphite bushings, extreme care must

be taken to prevent breaking. Carbon graphite is a brittle

material and easily cracked. If cracked, the bushing will

quickly disintegrate. Using a lubricant and adding a chamfer

on the bushing and the bushing bore will help in installation.

The additional precautions listed below must be followed for

proper installation.

1. A press must be used for installation.

2. Be certain bushing is started straight.

3. Do not stop pressing operation until bushing is in proper

position. Starting and stopping will result in a cracked

bushing.

4. Check bushing for cracks after installation.

THRUST BEARING ADJUSTMENT

INSTALLATION OF CARBON

GRAPHITE BUSHINGS

PUMP

SIZE MODEL

STANDARD

END

CLEARANCE

(Inch)

TURN BRG.

HOUSING

C.C.W.

LENGTH

ON O.D.

(Inch)

ADDITIONAL

LENGTH ON BRG.

HOUSING O.D. FOR

EACH .001” OF END

CLEAR.

(Inch)

N

324A

4324A

324AH

4324AH

324E

324EH

323A

323E

4323A

327A

4327A

.015

6.09

.41

R

RS

324A

4324A

323A

4323A

327A

4327A

.020

9.09

.45

8. Install thrust bearing assembly and adjust end clearance.

Refer to Thrust Bearing Adjustment.

9. Draw seal plate up to seal box face by evenly tightening

gland nuts until seal plate is securely fastened.

10. Connect circulation line or vent stuffing box for seals

without circulation line until liquid is present on start up.

NOTE: For maximum seal life, circulation line should

be used.

11. Refer to Assembly on page 6 to complete assembly.

1. Make sure the pump is not running and all power to

drive the pump is “locked out”.

2. Loosen the two set screws in the outer face of the bearing

housing and rotate the bearing housing in a clockwise

direction until it cannot be turned any more. This ensures

the rotor is all the way forward and is touching the head.

It will not be possible to turn the rotor by hand in this

location.

3. Make a mark on the outside diameter of the bearing

housing and a corresponding mark on the bearing

bracket

.

4. Rotate the bearing housing in a counter clockwise

direction until the mark on the outside diameter of the

bearing housing is past the mark on the bearing bracket

by 6.09 in. (155 mm) or 9.09 in. (231 mm) See chart

above. This will provide the standard end clearance for

the pump. Operating the pump at higher temperatures or

viscosities may require additional end clearance. Contact

your local Viking representative for those clearances.

Note that 0.41 in. (10.4 mm) or 0.45 in. (11.5mm) rotation

on the outside diameter of the bearing housing equals

0.001 in. (0.03mm) additional end clearance.

5. Tighten the setscrews.

6.

Rotate the rotor shaft by hand to make sure it turns

freely.

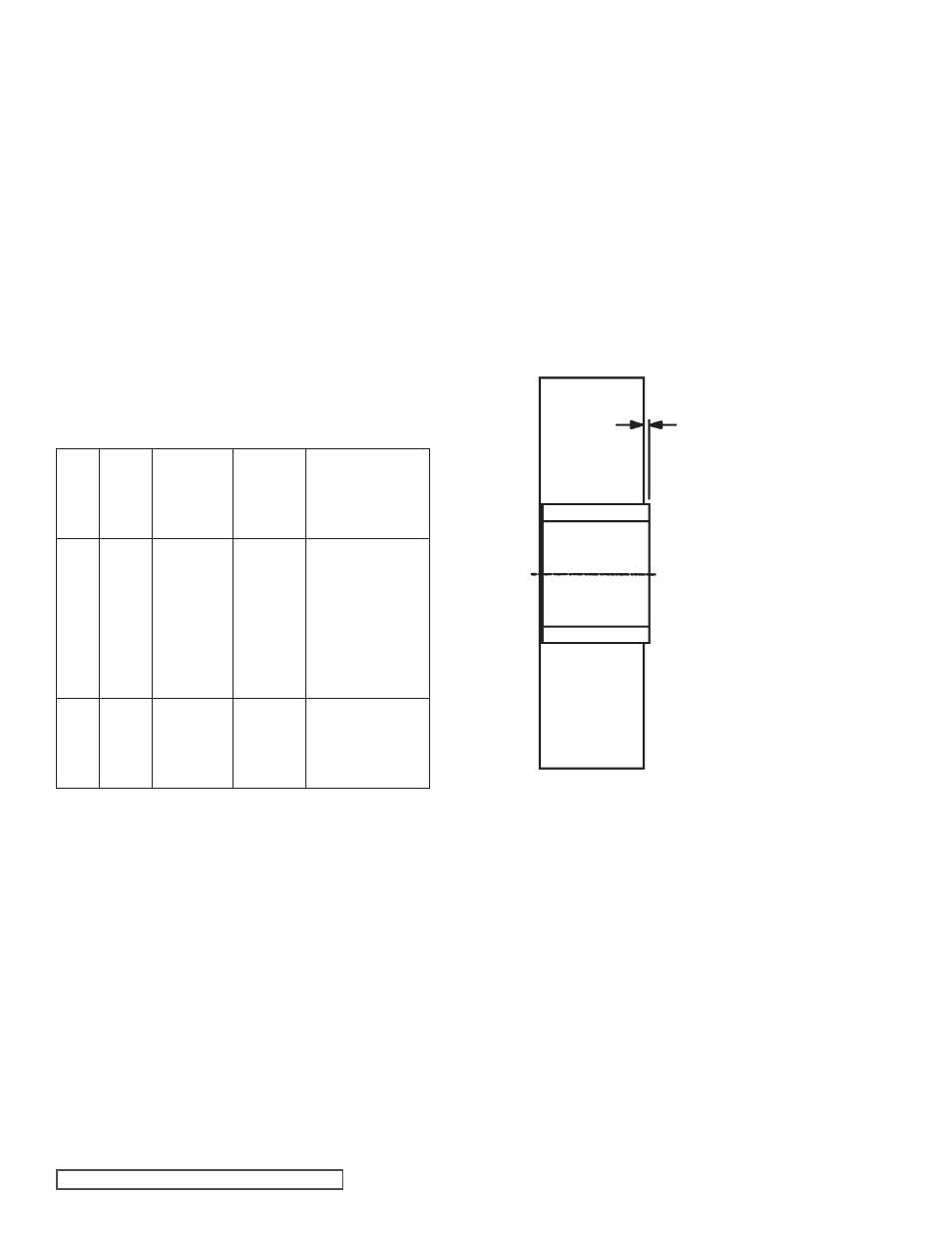

FIGURE 11

IDLER AND BUSHING ASSEMBLY

NOTE:

The R327A and R4327A (stainless steel) pumps have a

special idler-bushing arrangement.

See Figure 11.

The Carbon Graphite idler bushing extends beyond the idler

face on one side of the idler. This side of the idler is placed

toward the head, which allows the Carbon Graphite bushing

to contact the head and provide clearance between the

stainless steel idler face and the head. The Carbon Graphite

bushing extension is 0.008 – 0.012”

(See Figure 11).

The idler bushing has a high interference fit and must be

installed by heat shrinking. The idler must be heated to 600º

F for 1.5 hours before installing the idler bushing. The idler

bushing is to extend beyond the idler face 0.008 – 0.012”.

Install the idler & bushing over the idler pin placing the side of

the idler with the bushing extension against the head. Adjust

end clearance as stated in

Thrust Bearing Adjustment.

HEAD

THIS

SIDE

ROTOR

THIS

SIDE

BUSHING EXTENSION

BEYOND IDLER FACE

0.012

0.008