Pressure adjustment important, Pressure relief valve instructions, Disassembly assembly – Viking Pump TSM630.3: N-RS Universal Seal User Manual

Page 11: Heat cartridges, Warning

SECTION TSM 630.3

ISSUE

H

PAGE 11 OF 13

If a new spring is installed or if pressure setting of pressure

relief valve is to be changed from that which the factory has

set, the following instructions must be carefully followed.

1. Carefully remove valve cap, which covers adjusting

screw.

In ordering parts for pressure relief valve, always give

model number and serial number of pump as it appears on

nameplate and name of part wanted. When ordering springs,

be sure to give pressure setting desired.

PRESSURE ADJUSTMENT

IMPORTANT

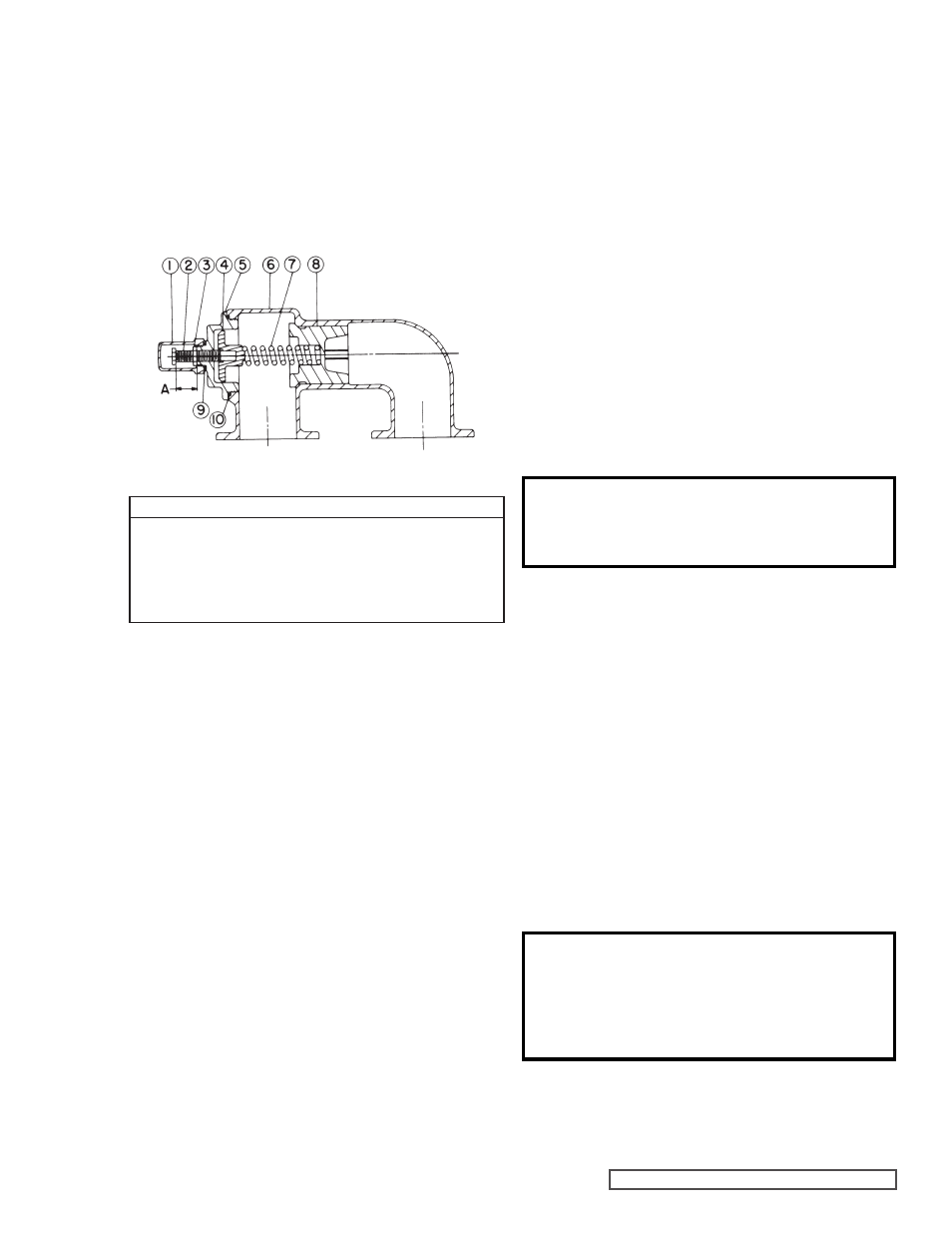

FIGURE 12

PRESSURE RELIEF VALVE

INSTRUCTIONS

VALVE - LIST OF PARTS

1. Valve Cap

6. Valve Body

2. Adjusting Screw

7. Valve Spring

3. Lock Nut

8. Poppet

4. Spring Guide

9. Cap Gasket

5. Bonnet

10. Bonnet Gasket

Mark valve and head before disassembly to insure proper

reassembly.

1. Remove valve cap.

2. Measure and record length of extension of adjusting

screw.

Refer to “A” on Figure 12.

3. Loosen locknut and back out adjusting screw until spring

pressure is released.

4. Remove bonnet, spring guide, spring and poppet from

valve body. Clean and inspect all parts for wear or

damage and replace if necessary.

Reverse procedures outlined under Disassembly. If valve

is removed for repairs be sure to replace in same position.

Relief valve adjusting screw cap must always point towards

suction side of pump. If pump rotation is reversed, remove

relief valve and turn end for end.

DISASSEMBLY

ASSEMBLY

NOTE:

The “RS” size pumps

use a two idler and bushing

arrangement.

For RS327A and RS4327A pumps using non-galling stainless

steel alloy (770) material idlers, the bushings are installed

flush with the idler face.

INSTALLATION INSTRUCTIONS:

WARNING !

The pump needs to be properly grounded

before the heat cartridges are installed.

1. Spacers should be installed between the foot of the

pump and the base. This will create an air gap between

the pump and base to limit heat transfer to the base.

2. Coat the threads of the heat cartridge with an anti-seize

compound prior to installation. Install heat cartridges into

the tapped ports on the head and bracket in the locations

shown in

Figure 13 below. Figure 13 also shows the

location for the thermocouple. The number of heaters

used and the total wattage for each pump size is given in

Table 1 below. ¾” heat cartridges should be tightened to

20 ft-lbs.

3. Viking recommends installing a closed loop temperature

controller with a control algorithm that will minimize or

prevent overshooting the set point temperature. The set

point temperature needs to be slightly higher than the

melting point and significantly lower than the flash point

or boiling point of the liquid being pumped. Viking does

offer a controller for use with our heat cartridges. Ask

your local Viking distributor for details.

2. Loosen locknut (which locks adjusting screw so pressure

setting will not change during operation of pump).

3. Install a pressure gauge in discharge line for actual

adjusting operation.

4. Turn adjusting screw in to increase pressure and out to

decrease pressure.

5. With discharge line closed at point beyond pressure

gauge and pump running, gauge will show maximum

pressure that the valve will allow (full bypass).

WARNING !

Setting the set point temperature higher

than necessary will not make the pump

heat any faster and will shorten the life

of the heat cartridges.

4. Properly insulate the pump to minimize heat loss.

The pump will not heat properly if it is not insulated.

This section applies to 324E Series only.

HEAT CARTRIDGES