Helical & bevel reducer lubrication types – Viking Pump NORD TSM For Helical Inline Reducers User Manual

Page 14

DRIVESYSTEMS

HELICAL & BEVEL REDUCER

LUBRICATION TYPES

RETAIN FOR FUTURE USE

U11000 - 1 of 2

Oil Formulation Codes

MIN-EP -

Mineral Oil with EP Additive

PAO-EP - Synthetic

Polyalphaolefi n Oil with EP Additive

PAO -

Synthetic

Polyalphaolefi n Oil

PG

-

Synthetic Polyglycol Oil

FG -

Food-Grade

Oil

FG-PAO -

Food-Grade, Synthetic Poyalphaolefi n Oil

FG-PG

-

Food-Grade, Synthetic Polyglycol Oil

Lubrication Notes

• Avoid using (EP) gear oils in worm gears that contain

sulfur-phosphorous chemistries, as these additives can

react adversely with bronze worm gears and accelerate

wear.

• Food grade lubricants must be in compliance with FDA 212

CFR 178.3570 and qualify as a NSF-H1 lubricant. Please

consult with lubrication manufacturer for more information.

• When making a lubrication change, check with the

lubrication supplier to assure compatibility and to obtain

recommended cleaning or fl ushing procedures.

• Do not to mix different oils with different additive pack-

ages or different base oil formulation types. Polyglycol (PG)

oils are not miscible with other oil types and should never

be mixed with mineral oil or polyalphaolefi n (PAO)

synthetic

oil.

www.nord.com/docs

06.01.11

NORD Gear Corporation

Toll Free in the United States: 888.314.6673

NORD Gear Limited

Toll Free in Canada: 800.668.4378

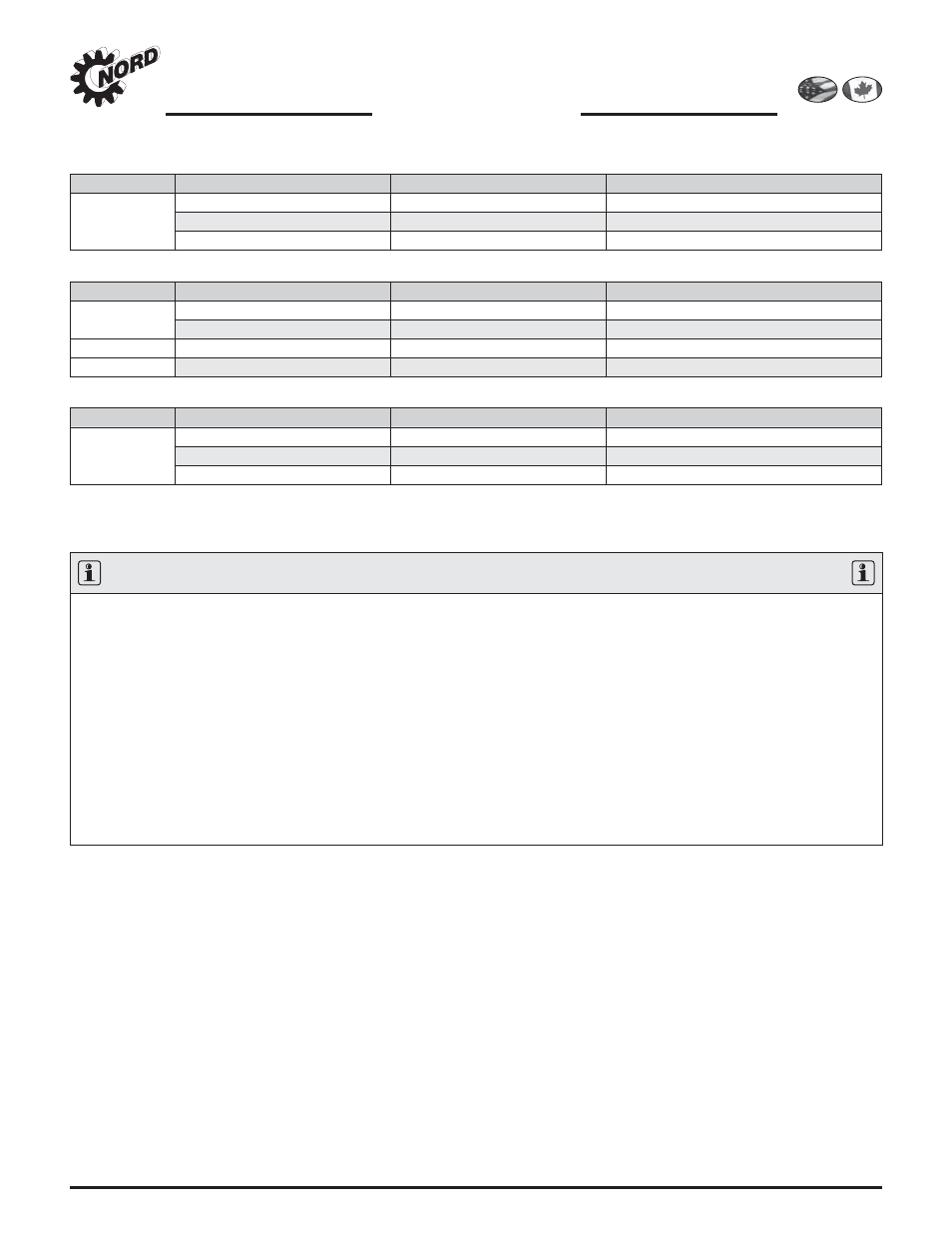

Lubrication Tables – Helical and Bevel Gear Units

Standard Oil Lubricants

ISO Viscosity

Oil Type

Ambient Temperature Range

Manufacturer Brand / Type

VG220

MIN-EP

0 to 40 ºC (32 to 104 ºF)

Mobil / Spartan EP220

PAO

-35 to 60 ºC (-31 to 140 ºF)

Mobil / SHC630

FG

-5 to 40 ºC (23 to 104 ºF)

Fuchs / FM220

Optional Oil Lubricants

ISO Viscosity

Oil Type

Ambient Temperature Range

Manufacturer Brand / Type

VG460

PAO

-35 to 80 ºC (-31 to 176 ºF)

Mobil / SHC634

FG-PAO

-35 to 80 ºC (-31 to 176 ºF)

Mobil / Cibus SHC460

VG220

FG-PAO

-34 to 60 ºC (-29 to 140 ºF)

Mobil / Cibus SHC220

VG150

PAO

-35 to 25 ºC (-30 to 77 ºF)

Mobil / SHC629

Grease Options (applied to greased bearings and seal cavities)

NLGI Grade

Grease Type / Thickener

Ambient Temperature Range

Manufacturer Brand / Type

NLGI 2

Standard / Li-Complex

-30 to 60 ºC (-22 to 140 ºF)

Mobil Grease XHP222

High-Temperature / Polyurea

-25 to 80 ºC (-13 to 176 ºF)

Mobil Polyrex EP 2

Food-Grade / Al-Complex

-25 to 40 ºC (-13 to 104 ºF)

Mobil Grease FM222

Stocked Lubricants

Standard product on serviceable gear units

Standard product on maintenance free gear units

IMPORTANT NOTES

• The “Ambient Temperature” is intended to be an operation guideline based upon the typical properties of all the

lubricant. The viscosity and other properties of the lubricant change based upon load, speed, ambient conditions, and

reducer operating temperatures. The user should consult with their lubrication supplier & NORD gear before considering

changes in oil type or viscosity.

• To prevent reducer overheating, observe the maximum operating oil temperature limits:

Mineral Oil: 80-85 ºC (176 – 180 ºF).

Synthetic Oil: 105 ºC (225 ºF).

• In the following instances, please consult NORD for specifi c recommendations:

√ Gear units will operate in high ambient temperature conditions exceeding 40 ºC (104 ºF).

√ Gear units will operate in cold ambient temperature conditions approaching 0 ºC (32 ºF) or lower.

√ Lower than an ISO VG100 viscosity oil is being considered for a cold-temperature service.

√ Fluid grease is required for lubricating the gear unit.

• Observe the general lubrication guidelines outlined in user manual U10750.