Assembly, Abearing housing, Danger – Viking Pump TSM230: Hygienic Series User Manual

Page 7

SECTION TSM

230

ISSUE

B

PAGE 7 OF 15

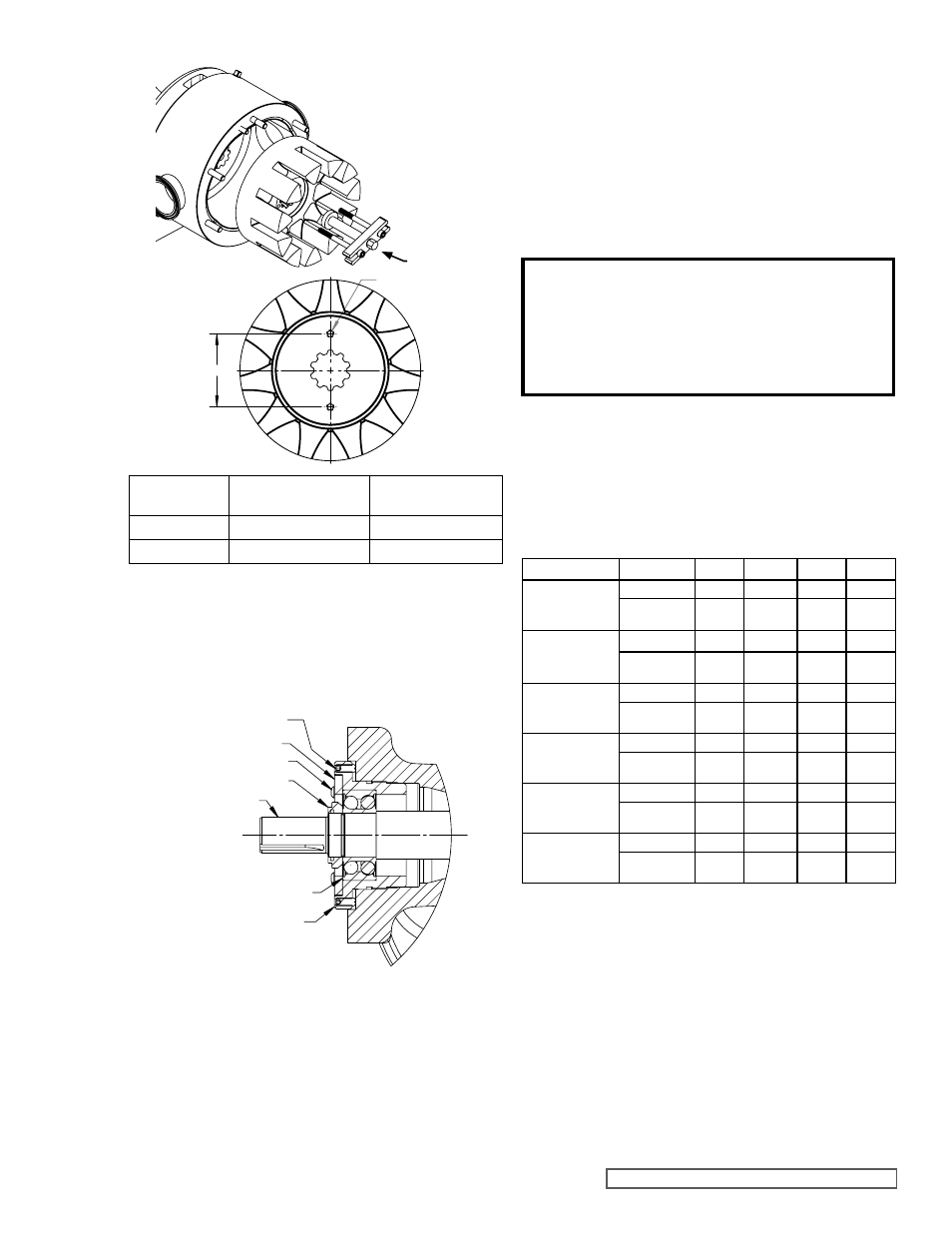

FIGURE 6

ROTOR REMOVAL

A

2X H

GEAR PULLER

Pump Size

Hole Spacing ‘A’

(inch)

Thread Size ‘H’

(inch)

H, HL

1 - 3/4

1/4 - 20

KS-LS

2 - 1/2

1/4 - 20

17. Loosen the two setscrews in the face of the bearing

housing and turn the thrust bearing assembly counter-

clockwise with a pin type spanner wrench and remove

from bracket.

See Figure 7.

ASSEMBLY

DANGER !

BEFORE STARTING PUMP, BE SURE ALL

DRIVE EQUIPMENT GUARDS ARE IN PLACE.

FAILURE TO PROPERLY MOUNT GUARDS

MAY RESULT IN SERIOUS INJURY OR DEATH.

It is recommended that new O-rings be used for reassembly

of the pump.

All O-rings should be lightly lubricated with an appropriate

lubricant that is suitable for the application before installing.

The fastener torque values are listed in

Table 1. Use food

grade anti-seize when installing all fasteners except for the

locknut.

FIGURE 7

THRUST BEARING ASSEMBLY

A

A

BEARING HOUSING

SHAFT

LOCKNUT

OUTER BALL BEARING

BEARING HOUSING

SET SCREW

CAPSCREW

END CAP

18. Disassemble the thrust bearing assembly by removing

the outer ball bearing.

See Figure 7.

19. Clean all parts thoroughly and examine for wear and

damage. Check ball bearings, idler bushing, and idler pin

and replace if necessary. The casing should be examined

for wear, particularly in the area between the ports.

Check all other parts for nicks, burrs, excessive wear and

replace if necessary. All O-rings should be replaced.

Make sure bearings are clean, and then check for

roughness. Roughness can be determined by turning

outer race by hand. Replace bearings if necessary.

Be sure the shaft is free from nicks, burrs and foreign

particles that might damage the mechanical seal.

Scratches on the shaft in the seal area will provide

leakage paths under the mechanical seal. Use a fine

emery cloth to remove scratches or sharp edges.

TABLE 1

FASTENER TORQUE VALUES

Description

H-HL KS-KK LQ-LL LS

End Cap

Capscrews

(Button Head)

Thread Size #10-24

#10-24

#10-24

1/4”

Anti-Seize

Torque (ft-lbs)

1-2

1-2

1-2

4-5

Anti-Rotation

Washer Capscrew

(Button Head)

Thread Size

M6

M8

3/8”

3/8”

Anti-Seize

Torque (ft-lbs)

2-3

5-6

13-14

13-14

Rotor Retainer

Thread Size

3/8”

1/2”

1/2”

1/2”

Anti-Seize

Torque (ft-lbs)

30-35

30-35

30-35

30-35

Idler Pin Capscrew

(Button Head)

Thread Size

1/4”

1/4”

3/8”

3/8”

Anti-Seize

Torque (ft-lbs)

4-5

4-5

13-14

13-14

Head Nuts

Thread Size

1/4”

5/16”

3/8”

3/8”

Anti-Seize

Torque (ft-lbs)

4-5

7-8

13-14

13-14

Locknut

Size

N-05

N-07

N-07

N-08

Dry Torque

(ft-lbs)

50-70

100-130 100-130 120-150

ASSEMBLY FOR MECHANICALLY SEALED PUMPS

1. On jacketed pumps, install jacket tubing onto the bracket

by squeezing the tubing between the slots of the bracket

flange. Make sure that the tubing does not extend past the

flange surface and interfere with installation of the casing.

2. Use an arbor press to install the inner single row ball

bearing onto the shaft.

Refer to Disassembly and

Installation of Inner Ball Bearing, page 14. The inner

bearing in this pump is a “Sealed for Life” bearing that has

seals on both sides. This bearing can be installed either

side first and does not need to be packed with grease.