Required clearance for disassembly – Viking Pump TSM230: Hygienic Series User Manual

Page 5

SECTION TSM

230

ISSUE

B

PAGE 5 OF 15

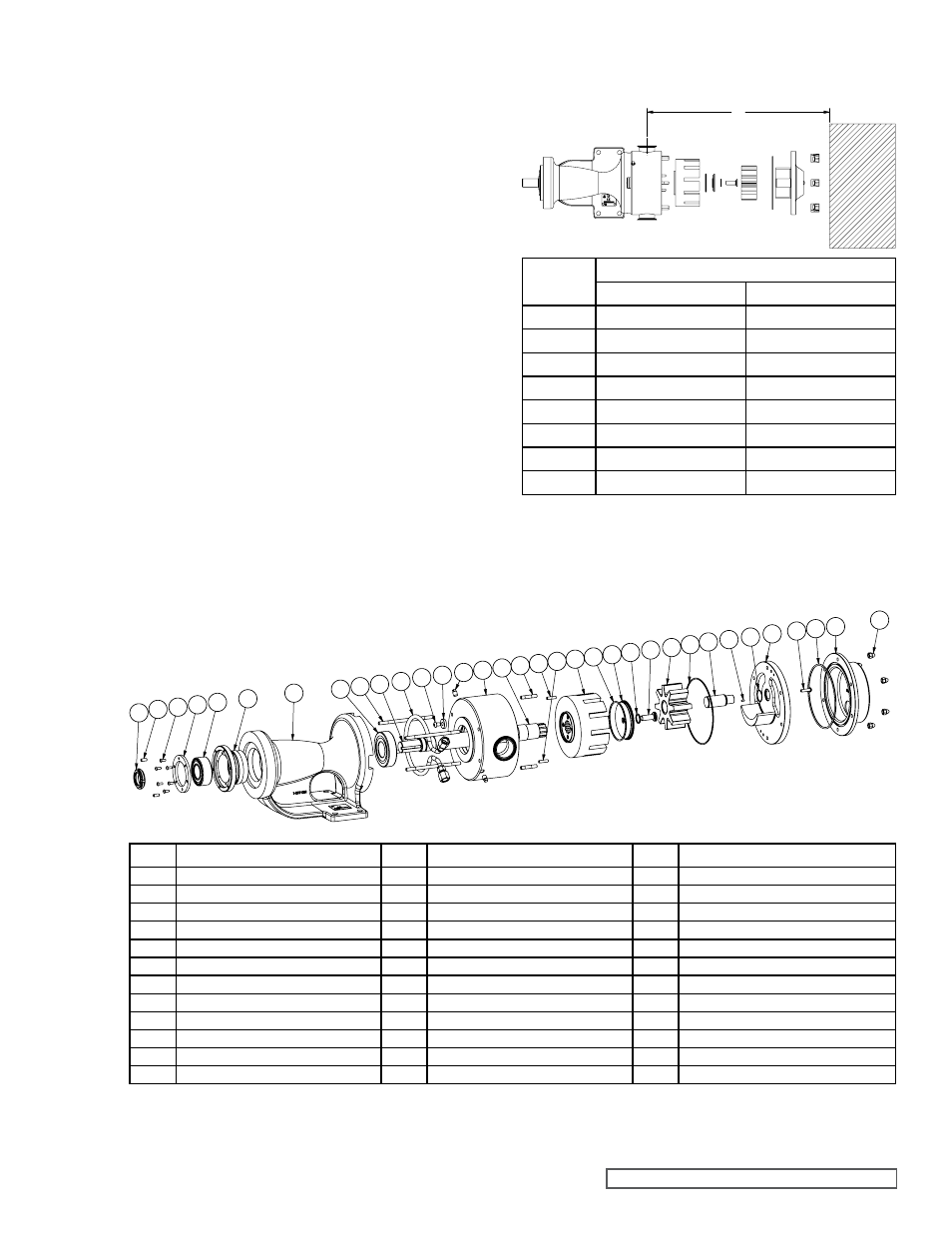

ITEM

NAME OF PART

ITEM

NAME OF PART

ITEM

NAME OF PART

1

Locknut

36A

Rotor

53

Head Alignment Dowel Pin

3

End Cap

36B

Shaft

53A

Large Head Alignment Dowel Pin

3B

Capscrew for End Cap

37

Idler and Bushing Assembly

64

Stud for Casing

6

Ball Bearing (Outer)

39

Idler Pin

71

Rotor Retainer Cap O-ring

7

Bearing Housing

39A

Idler Pin Dowel Pin

72

Rotor Retainer Cap

7A

Set Screw

39B

Idler Pin O-ring

73

Rotor Retainer O-ring

19

Seal (Not Shown)

39C

Capscrew for Idler Pin

74

Rotor Retainer

20

Ball Bearing (Inner)

40

Head

75

Capscrew for Anti-Rotation Washer

27

Bracket

41

O-ring for Jacket Head Plate

76

Anti-Rotation Washer

30

Pipe Plug

42

Jacket Head Plate

80

Jacket Tubing for Bracket

31

Casing

43

Stud for Head

35

Head O-ring

44

Nut for Head

FIGURE 4

EXPLODED VIEW FOR HYGIENIC SERIES MODELS

1 7A

3B

6

7

27

20

36B

64

75 76

31

30

43 53

36A 71 72

73 74 37

35 39

3

39B

36B

53A

39A

40

44

39C 41 42

80

Pump

Size

Required to Remove Pump Internals (AA)

Inch

mm

H

14-1/4

362

HL

15-1/2

394

KS

19-1/4

489

K

19-3/4

502

KK

20-3/4

527

LQ

23

584

LL

24

610

LS

24-3/4

629

REQUIRED CLEARANCE FOR

DISASSEMBLY

FIGURE 3

CLEARANCE FOR DISASSEMBLY

AA

5. Ensure that the cleaning solution is compatible with all of

the pump materials.

SOILED ROTOR RETAINER CLEANING PROCEDURES:

1. Use steps 1, 4 and 6-8 from the disassembly procedures

to remove the rotor retainer components.

2. If rotor retainer blind tapped hole is soiled, submerge

and soak rotor retainer for 5 minutes in Clean Out of

Place tank with suitable cleaning solution.

3. Scrub both external and internal threads with appropriate

bristle brush and suitable cleaning solution.

4. Rinse with clean water and dry blind tapped hole with

clean air.

5. Use new O-rings when reassembling the pump. For

mechanically sealed pumps, follow steps 27 and 29-31

from the assembly procedures to reassemble the pump.

For O-ring sealed pumps, follow steps 13 and 15-17

from the assembly procedures to reassemble the pump.

As long as the thrust bearing was not adjusted, the end

clearance should still be set correctly. Verify the end

clearance and adjust if necessary before putting pump

back into service. If the locknut needs to be retightened

or the end clearance needs to be adjusted, follow the

complete assembly procedures. Do not tighten the

locknut or make major (> 0.005”) adjustments to the end

clearance of mechanically sealed pumps while the seal

is installed in order to avoid damaging the seal faces.

Note: Install new rotor retainer if debris remains after

cleaning. It is recommended that the rotor retainer O-rings be

replaced every 12 months to maintain a tight seal.