Tweco SL100 RPT User Manual

Page 5

June 6, 2003

5

Manual 0-2937

2. Main Arc Extinguishes

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Cutting current too high

d. Work cable disconnected

e. Worn torch parts

f. Non - Genuine Thermal Dynamics Parts

3. Excessive Dross Formation

a. Cutting speed too slow

b. Torch standoff too high from workpiece

c. Worn torch parts

d. Improper cutting current

e. Non - Genuine Thermal Dynamics Parts

4. Short Torch Parts Life

a. Oil or moisture in air source

b. Exceeding system capability (material too thick)

c. Excessive pilot arc time

d. Gas pressure too low

e. Improperly assembled torch

f. Non - Genuine Thermal Dynamics Parts

5. Difficult Starting

a. Worn torch consumables

b. Non - Genuine Thermal Dynamics Parts

6. Torch will not pilot

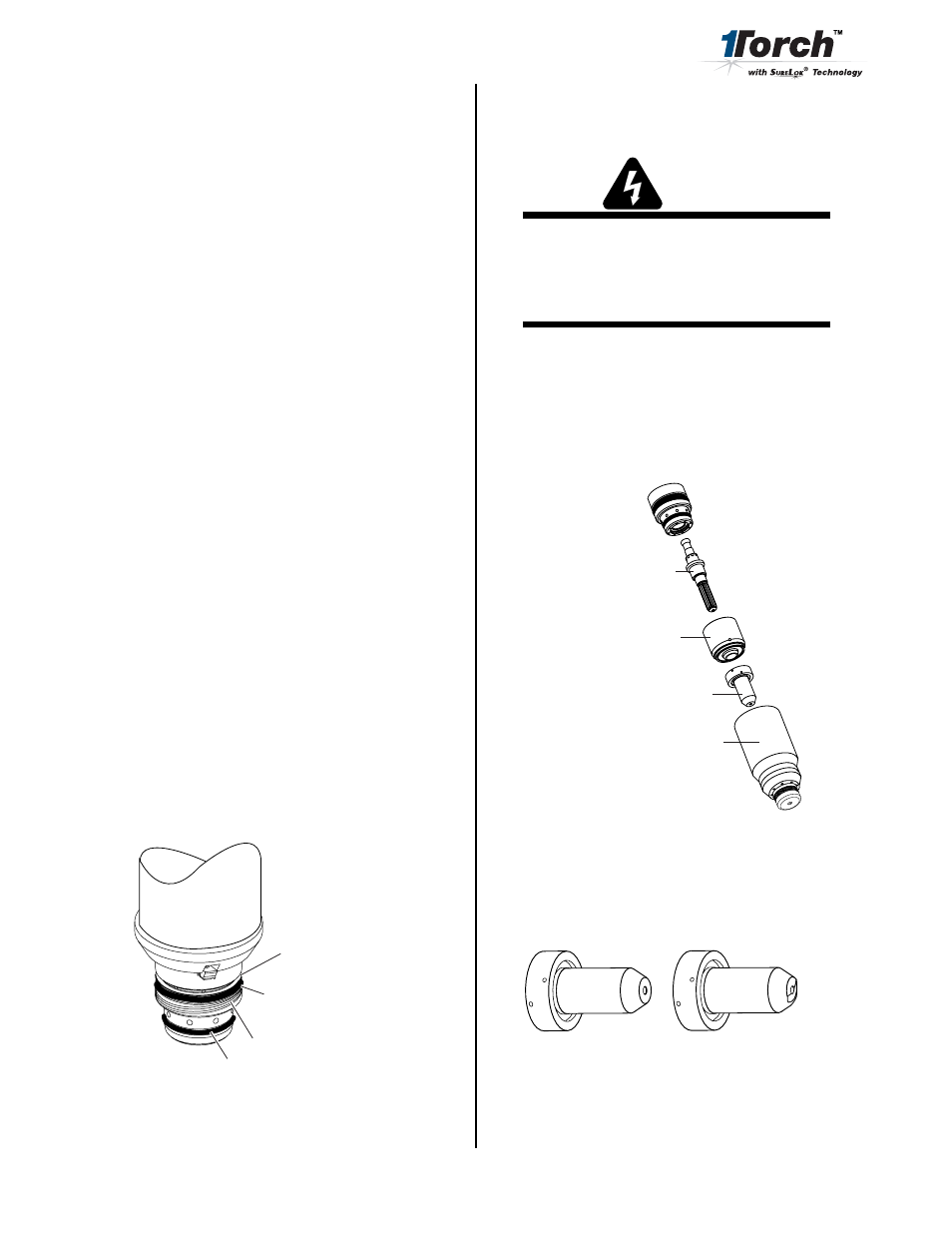

a. Upper O-ring on torch head in wrong position

Upper Groove

with Vent Holes

Must Remain Open

Threads

Upper O-Ring

in Correct Groove

Lower O-Ring

A-03725

Inspection and Replacement of

Consumable Torch Parts

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light of the Power Supply is ON.

Remove the consumable torch parts.

1. Inspect the cup for damage. Wipe it clean or replace

if damaged. Slag built up on the shield cup that can-

not be removed may affect the performance of the

system.

A-03598

Electrode

Starter Cartridge

Tip

Shield Cup

Assembly

Torch Head

2. Check the tip for excessive wear (indicated by an elon-

gated or oversized orifice). Clean or replace the tip if

necessary.

Good Tip

Worn Tip

A-03406