Common operating faults – Tweco SL100 RPT User Manual

Page 4

June 6, 2003

4

Manual 0-2937

2. Fit the starter cartridge and desired tip onto the elec-

trode.

NOTE

Refer to the consumables selection chart for the

proper combination of torch parts, including shield

retainers and cups.

3. Fit the shield cup onto the torch head.

4. Hand tighten the shield cup until it is seated on the

torch head. Do not use tools to tighten the cup. If

resistance is felt when installing the cup, check the

threads before proceeding.

NOTE

When operating the torch in a normal condition, a

small amount of gas vents through the gap between

the shield cup and torch handle. Do not attempt to

over tighten the shield cup as irreparable damage

to internal components may result.

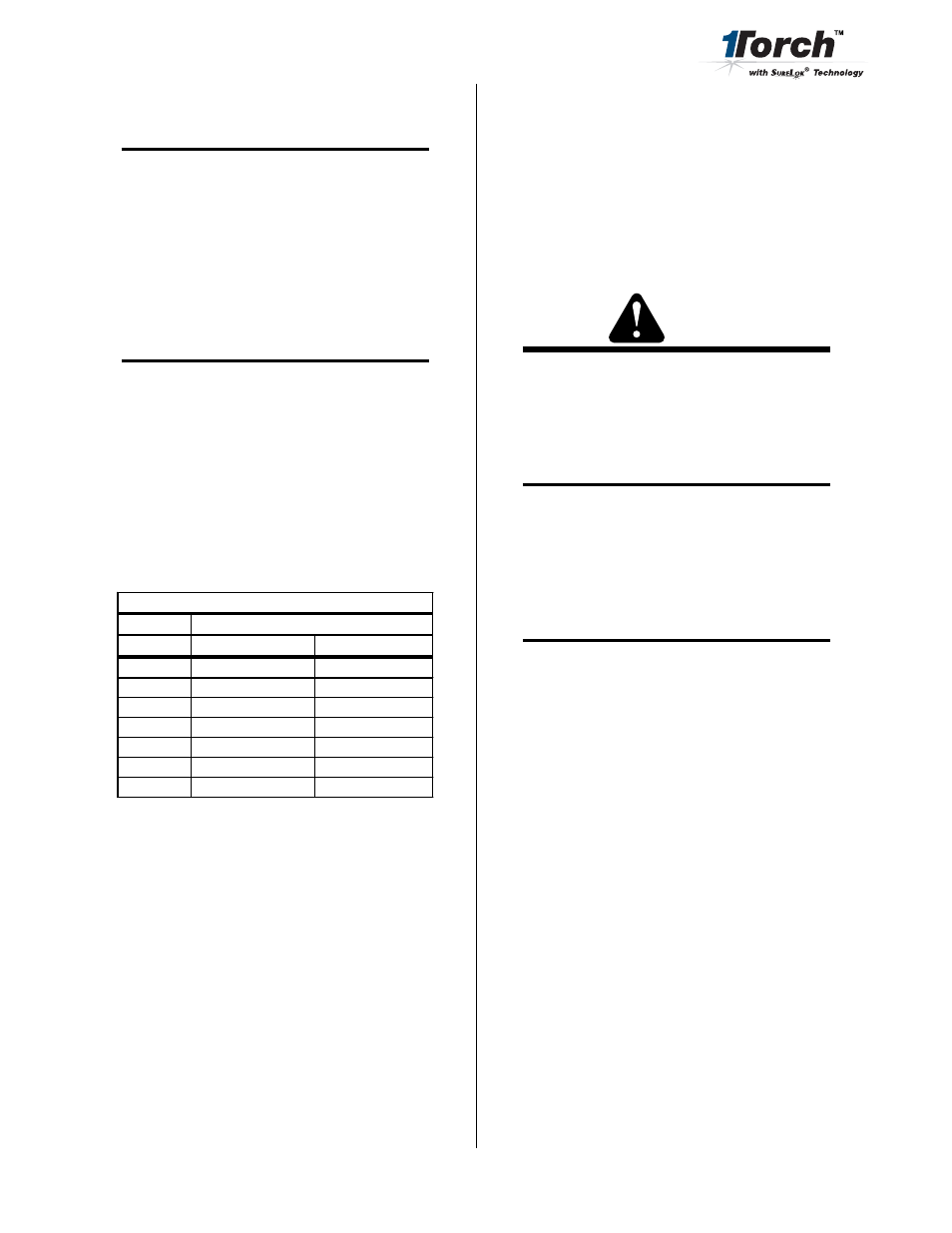

Operating Gas Pressure

Set gas pressure at the power supply regulator according

to the following chart. This chart is a guide only; adjust

as necessary for best performance.

Tip

Up to 25' / 7.6 m

50' / 15.2 m

30A

55 psi / 3.8 bar

60 psi / 4.1 bar

40A

55 psi / 3.8 bar

60 psi / 4.1 bar

50/55A

60 psi / 4.1 bar

65 psi / 4.5 bar

60A

60 psi / 4.1 bar

65 psi / 4.5 bar

70A

60 psi / 4.1 bar

65 psi / 4.5 bar

80A

60 psi / 4.1 bar

65 psi / 4.5 bar

90 / 100 A

65 psi / 4.5 bar

70 psi / 5.2 bar

Total Leads Length

SL100 Gas Pressure Settings

Sequence of Operation

1. Turn on power and adjust gas pressure on the Power

Supply pressure gauge. Refer to the chart for opti-

mum pressure settings for the combination of torch

consumables and total leads lengths (including exten-

sions) in use.

2. Adjust current output on the Power Supply to match

the selected tip and attach the work clamp firmly to

the work or to the cutting table.

WARNING

Maximum current for this torch is 100 Amps. Op-

eration of this torch at higher outputs may dam-

age the torch, the leads, the components, or the

Power Supply. DO NOT operate the torch at more

than 100 Amps.

NOTE

The gas preflow and postflow are characteristics of

the power supply and not a function of the torch.

3. Recommended standoff distance is 3/16" / 4.7 mm.

4. Follow normal recommended cutting practices as pro-

vided in the power supply operator's manual.

NOTE

When the shield cup is properly installed, there is

a slight gap between the shield cup and the torch

handle. Gas vents through this gap as part of nor-

mal operation. Do not attempt to force the shield

cup to close this gap. Forcing the shield cup against

the torch head or torch handle can damage compo-

nents.

Cutting With Machine Torch

The machine torch can be activated by remote control pen-

dant or by a remote interface device such as CNC.

Common Operating Faults

The following are the more common cutting faults and

the possible causes:

1. Insufficient Penetration

a. Cutting speed too fast

b. Torch tilted too much

c. Metal too thick

d. Worn torch parts

e. Cutting current too low

f. Non - Genuine Thermal Dynamics Parts