08 mig welding (gmaw) variables, Mig welding (gmaw) variables -7 – Tweco FP-165 Mini MIG Portable MIG Welder User Manual

Page 38

OpERATION

FIREpOwER Fp-125, 135, 165

Operation

4-7

Manual 0-5123

4.08 MIG Welding (GMAW) Variables

Most of the welding done by all processes is on carbon

steel. The following items describe the welding variables

in short-arc welding of 24 gauge (0.024”, 0.6mm) to ¼”

(6.4mm) mild sheet or plate. The applied techniques and

end results in the GMAW process are controlled by these

variables.

pre-selected Variables

Pre-selected variables depend upon the type of material

being welded, the thickness of the material, the welding

position, the deposition rate and the mechanical proper-

ties. These variables are:

1. Type of electrode wire

2. Size of electrode wire

3. Type of gas (not applicable to self-shielding wires

FCAW)

4. Gas flow rate (not applicable to self-shielding wires

FCAW)

primary Adjustable Variables

These control the process after Pre-selected Variables

have been found. They control the penetration, bead

width, bead height, arc stability, deposition rate and weld

soundness. They are:

1. Arc Voltage

2. Welding Current (wire feed speed)

3. Travel Speed

Secondary Adjustable Variables

These variables cause changes in primary adjustable

variables which in turn cause the desired change in the

bead formation. They are:

1. Stickout—distance between the end of the contact

tube (tip) and the end of the electrode wire. Keep

this at about 3/8” (10mm) stickout (as shown in

Figure 4-8).

Gas Nozzle

Tip to Work

Distance

Contact Tip (Tube)

Electrode Wire

Actual Stickout

Average Arc Length

Art: A-05109

Figure 4-9: Electrode Stick-Out

2. Wire Feed Speed. Increase in wire feed speed in-

creases weld current. Decrease in wire feed speed

decreases weld current.

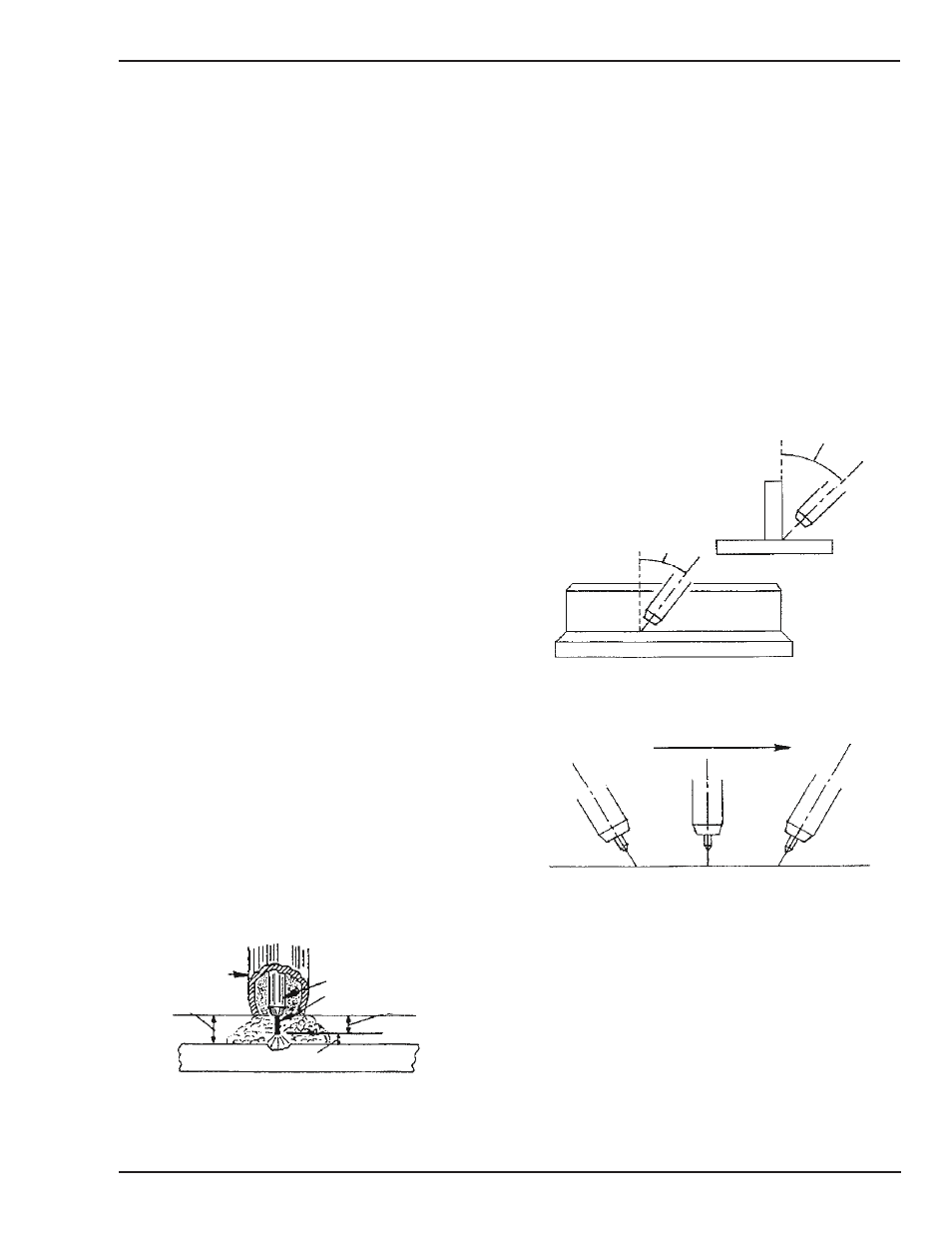

3. Nozzle Angle. (Figures 4-9 and 4-10) This refers

to the position of the welding gun in relation to

the joint. The transverse angle is usually one

half the included angle between plates forming

the joint. The longitudinal angle is the angle

between the center line of the welding gun and

a line perpendicular to the axis of the weld. The

longitudinal angle is generally called the Nozzle

Angle and can be either trailing (pulling) or leading

(pushing). Whether the operator is left-handed or

right-handed has to be considered to realize the

effects of each angle in relation to the direction

of travel.

Longitudinal

Angle

Transverse

Angle

Axis of Weld

Art: A-05110

Figure 4-10: Transverse and Longitudinal Nozzle Axes

Direction of Gun Travel

90º

Leading or "Pushing"

Angle (Forehand)

Trailing or "Pulling"

Angle (Backhand)

Art # A-05111

Figure 4-11: Nozzle Angle, Right-Handed Operator