06 basic welding technique, Basic welding technique -5 – Tweco FP-165 Mini MIG Portable MIG Welder User Manual

Page 36

OpERATION

FIREpOwER Fp-125, 135, 165

Operation

4-5

Manual 0-5123

4.06 Basic Welding Technique

General

Two different welding processes are covered in this

section, with the intention of providing the very basic

concepts in using the semi-automatic mode of welding.

In this mode, the welding gun is hand-held. The electrode

(welding wire) is then fed into a weld puddle and the arc

is shielded by a gas or gas mixture.

Setting of the power Supply

The settings of the FirePower requires some practice by

the operator in that the welding Power Supply has two

control settings that need to balance. These are the Wire

Speed control and the Voltage Control switches. The

welding current is determined by the Wire Speed control

(i.e., the current will increase with increased wire speed,

resulting in a shorter arc). Slower wire speed will reduce

the current and lengthen the arc. Increasing the welding

voltage hardly alters the welding current level, but length-

ens the arc. By decreasing the voltage, a shorter arc is

obtained with little change in welding current.

When changing to a different electrode wire diameter,

different control settings are required. A thinner electrode

wire needs more wire speed to achieve the same current

level.

A satisfactory weld cannot be obtained if the wire speed

and voltage switch settings are not adjusted to suit the

electrode wire diameter and dimensions of the work

piece.

If the wire speed is too high for the welding voltage,

“stubbing” will occur as the wire dips into the molten pool

and does not melt. Welding in these conditions normally

produces a poor weld due to lack of fusion. If however,

the welding voltage is too high, large drops will form on

the end of the electrode wire, causing spatter. The cor-

rect setting of voltage and wire speed can be seen in the

shape of the weld deposit and heard by a smooth regular

arc sound.

GAS METAL ARC WELDING (GMAW)

This process, also known as MIG welding, CO2 welding,

Micro Wire Welding, short arc welding, dip transfer weld-

ing, wire welding etc., is an electric arc welding process

which fuses together the parts to be welded by heating

them with an arc between a solid, continuous, consum-

able electrode and the work. Shielding is obtained from

an externally supplied gas or gas mixture. The process is

normally applied semi-automatically; however the process

may be operated automatically and can be machine oper-

ated. The process can be used to weld thin and fairly thick

steels, and some non-ferrous metals in all positions.

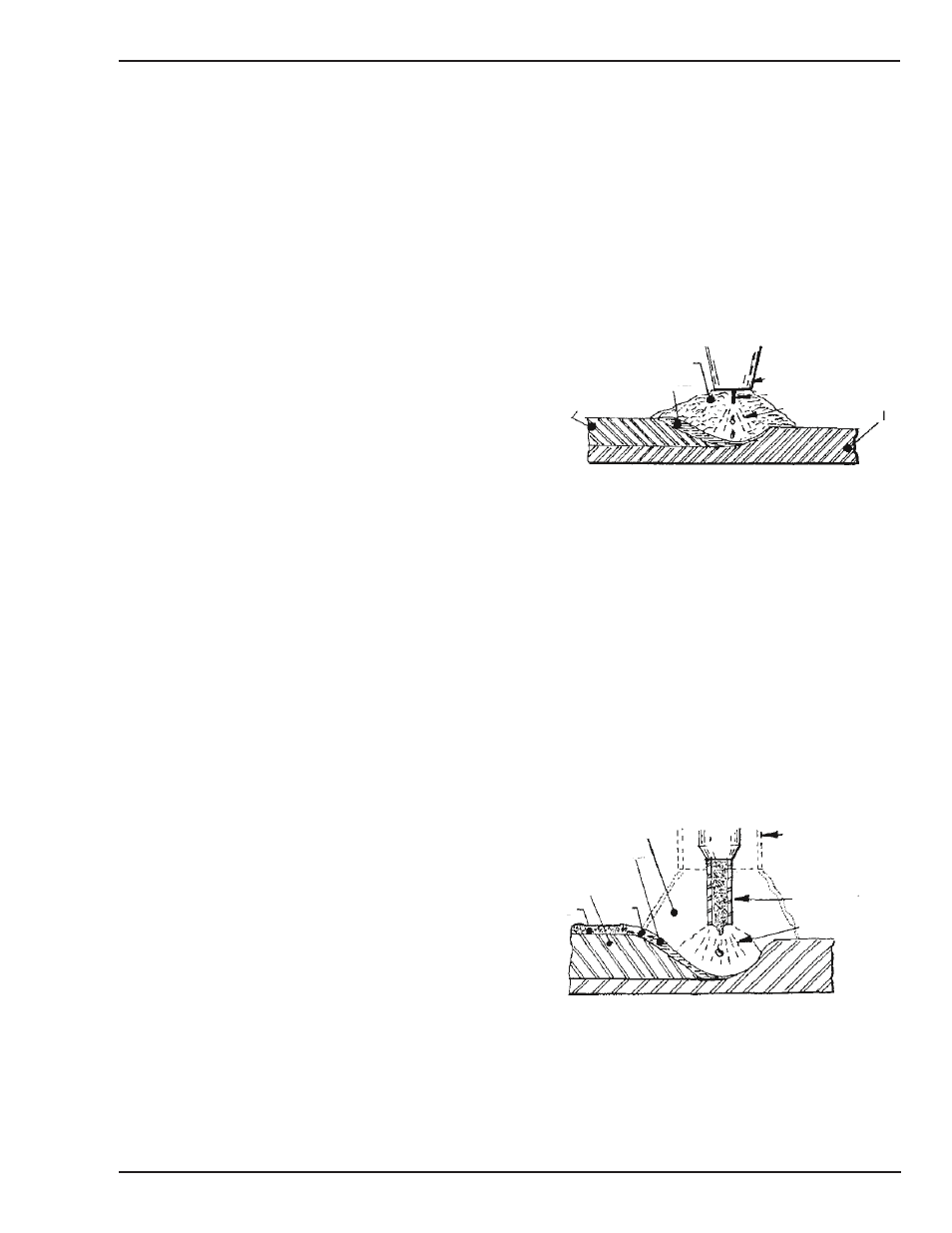

Base Metal

Arc

Electrode

Nozzle

Shielding Gas

Weld Metal

Solidified Weld

Metal

Art: A-05103

Figure 4-3: GMAW Process

FLUX CORED ARC WELDING (FCAW)

This process also known as Open arc, Innershied, FAB

Shield, etc., is an electric arc welding process which fuses

together the parts to be welded by heating them with an

arc between a continuous flux filled electrode wire and

the work. Shielding is obtained through decomposition of

the flux within the tubular wire. The process is normally

applied semi-automatically; however the process may be

applied automatically or by machine. It is commonly used

to weld large diameter electrodes in the flat and horizontal

position and small electrode diameters in all positions. The

process is used to a lesser degree for welding stainless

steel and for overlay work.

Arc

Flux Cored

Electrode

Nozzle (optional)

Gas (optional)

Molten Metal

Molten

Slag

Solid Weld

Metal

Slag

Art: A-05104

Figure 4-4: FCAW Process