Transmig vs 212 – Tweco VS212 Wire Feeder User Manual

Page 8

TRANSMIG VS 212

SAFETY INSTRUCTIONS

1-2

Manual No. 0-4949

13. In confined spaces or damp locations, do not use

a welder with AC output unless it is equipped with

a voltage reducer. Use equipment with DC output.

14. Wear a safety harness to prevent falling if working

above floor level.

15. Keep all panels and covers securely in place.

WARNING

ARC RAYS can burn eyes and skin; NOISE

can damage hearing.

Arc rays from the welding process

produce intense heat and strong ultraviolet

rays that can burn eyes and skin. Noise

from some processes can damage

hearing.

1. Wear a welding helmet fitted with a proper shade

of filter (see ANSI Z49.1 listed in Safety Standards)

to protect your face and eyes when welding or

watching.

2. Wear approved safety glasses. Side shields

recommended.

3. Use protective screens or barriers to protect others

from flash and glare; warn others not to watch

the arc.

4. Wear protective clothing made from durable,

flame-resistant material (wool and leather) and

foot protection.

5. Use approved ear plugs or ear muffs if noise level

is high.

WARNING

FUMES AND GASES can be hazardous to

your health.

Welding produces fumes and gases.

Breathing these fumes and gases can be

hazardous to your health.

1. Keep your head out of the fumes. Do not breath

the fumes.

2. If inside, ventilate the area and/or use exhaust at

the arc to remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied

respirator.

4. Read the Material Safety Data Sheets (MSDSs)

and the manufacturer’s instruction for metals,

consumables, coatings, and cleaners.

5. Work in a confined space only if it is well ventilated,

or while wearing an air-supplied respirator.

Shielding gases used for welding can displace air

causing injury or death. Be sure the breathing air

is safe.

6. Do not weld in locations near degreasing, cleaning,

or spraying operations. The heat and rays of the

arc can react with vapors to form highly toxic and

irritating gases.

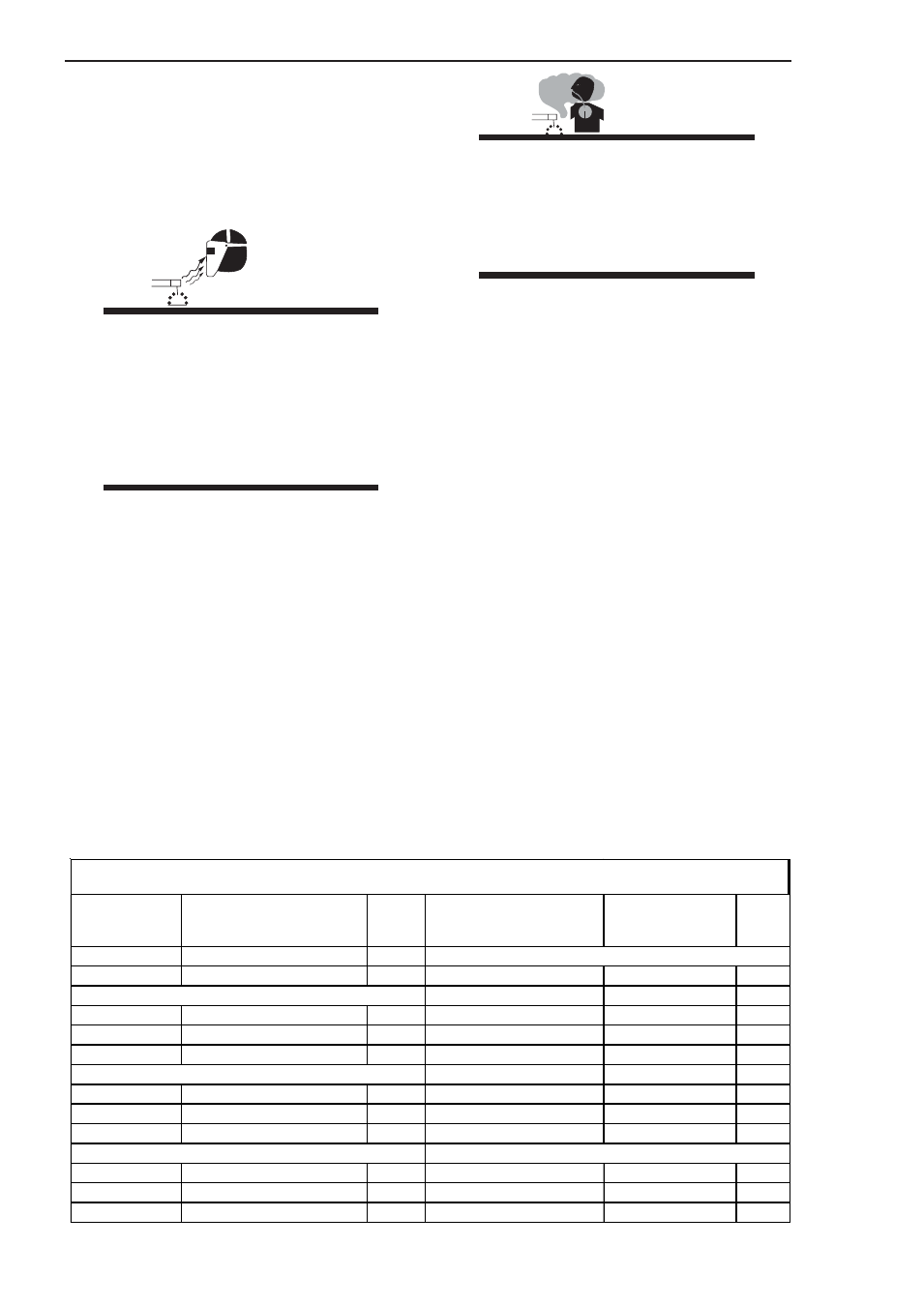

Welding or Cutting

operation

Electrode size Metal Thickness

or Welding Current

Filter

shade

no.

Welding or Cutting operation

Electrode size Metal

Thickness or Welding

Current

Filter

shade

no.

Torch soldering

All

2

Torch brazing

All

2 or 3

Non Ferrous base metal

All

11

Ferrous base metal

All

12

Light

Under 1 in., 25 mm

3 or 4

Gas tungsten arc welding (TIG)

All

12

Medium

1 – 6 in., 25 – 150 mm

4 or 5

Atomic Hydrogen welding

All

12

Heavy

Over 6 in., 150 mm

5 or 6

Carbon Arc welding

All

12

Plasma arc Welding

All

12

Light

Under 1/8 in., 3 mm

4 or 5

Carbon Arc Gouging

Medium

1/8 – 1/2 in., 3 – 12 mm

5 or 6

Light

12

Heavy

Over 1/2 in., 12 mm

6 or 8

Heavy

14

Under 5/32 in., 4 mm

10

Light

Under 300 Amp

9

Under 5/32 to ¼ in., 4 to 6.4mm

12

Medium

300 to 400 Amp

12

Over ¼ in., 6.4 mm

14

Heavy

Over 400 Amp

14

Eye protection filter shade selector for welding or cutting (goggles or helmet), from AWS A 8.2-73

Plasma arc cutting

Oxygen cutting

Gas metal arc welding

Gas welding

Shielded metal-arc welding (stick) electrodes