08 front panel controls and connections, 08 front panel controls and connections -6, Transmig vs 212 – Tweco VS212 Wire Feeder User Manual

Page 18

TRANSMIG VS 212

INTRODUCTION

2-6

Manual No. 0-4949

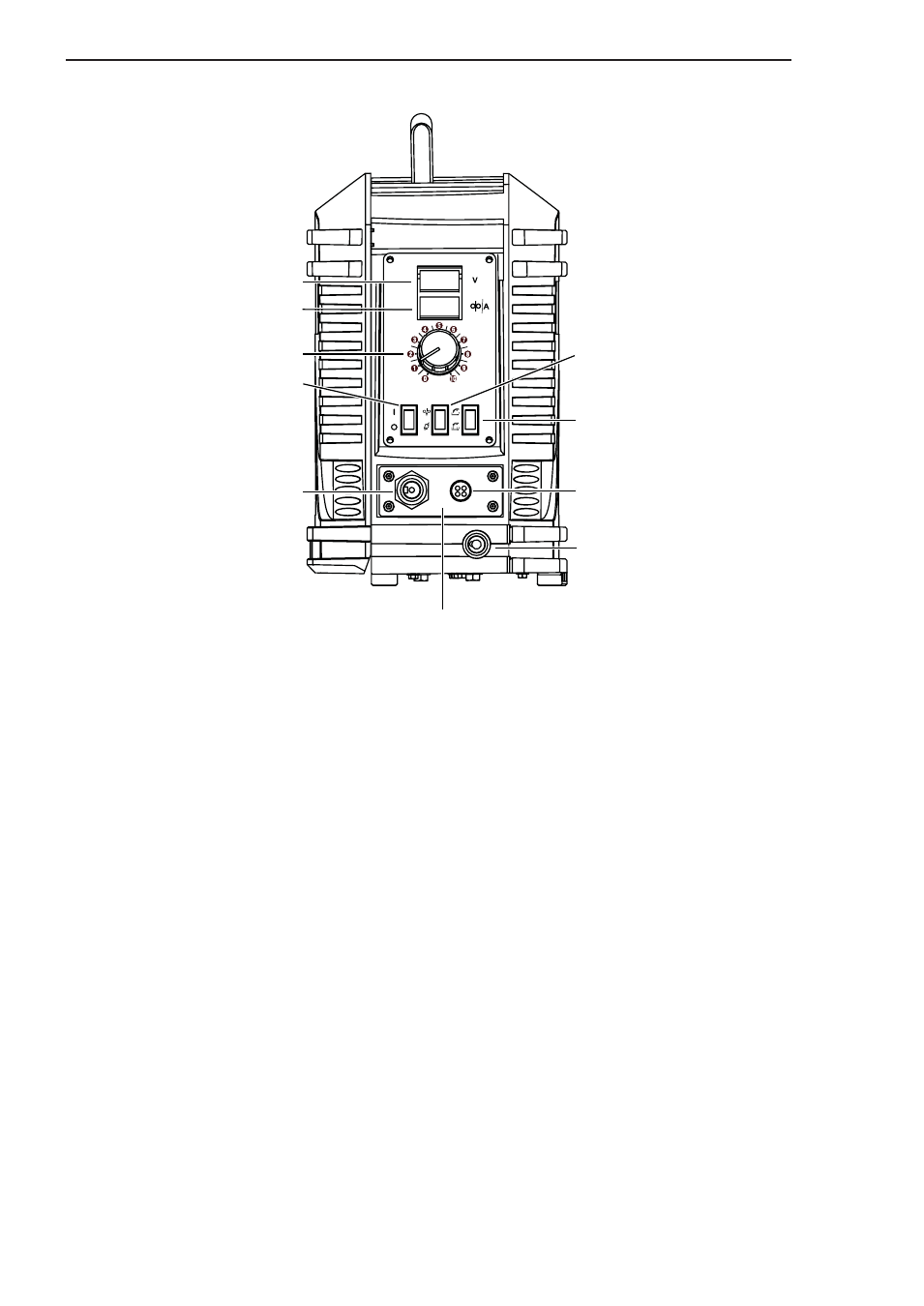

(2) Wire Feed Speed Control

(7) Gun Switch Receptacle

(9) Welding Gun Cable Connection

(10) Removable MIG Gun Cartridge (Tweco style shown)

(3) Wire Feed Speed/Amp Meter

(4) Arc Voltage Meter

(1) On/Off Power Switch

(5) Inch/Purge Switch

(6) 2T/4T Trigger Mode

Selector Switch

(8) Voltage Sensing Receptacle

25mm Dinse

Art # A-07136_AB

1. POWER ON/OFF SWITCH: This switch controls

input power only to the wire feeder and not to the

power source.

2. WIRE FEED SPEED CONTROL: This knob controls

the wire feed speed. The wire feed speed control

can be adjusted during setup or actual welding.

3. WIRE FEED SPEED/AMP METER: The wire feed

speed meter displays the actual wire feed speed

output of the wire feeder. This meter can be

changed to display the actual amperage output of

the power source by adjusting the DIP switches

located on the edge of the display board inside

the unit. Refer to Section 4.07 for details.

4. ARC VOLTAGE METER: The arc voltage meter

displays the actual voltage output of the power

source.

5. INCH/PURGE SWITCH: Depressing the INCH

portion of the switch will feed wire at a speed set

by the WFS control. The wire will not be electrically

hot when using the INCH switch. Depressing the

PURGE portion of the switch will allow shielding

gas to flow out of the welding gun without feeding

wire.

2.08 Front Panel Controls And Connections

6. TRIGGER HOLD SWITCH: This switch selects

either 2 Step or 4 Step gun switch mode.

7. GUN SWITCH RECEPTACLE: The gun switch

receptacle accepts the welding gun control wires.

The gun switch receptacle is where a gun switch

closure is inputted to the wire feeder.

8. VOLTAGE SENSING RECEPTACLE: This receptacle

serves as the voltage sensing point for the wire feeder

and must be connected to the work piece through

the voltage sensing lead for proper operation. If the

voltage sensing lead from the wire feeder and the

weld cable from the power source are not connected

to the work piece, the wire feeder will not work.

9. WELDING GUN CABLE CONNECTION: The welding

gun cable is connected to the wire feeder at this

point. Connections must be tight; otherwise,

arcing or overheating could result.

10.REMOVABLE MIG GUN CARTRIDGE (Patent

Pending): The whole cartridge is interchangeable

to accept competitive types of MIG gun

connections. No external adapters required. See

Appendix 2 and 3 for installation information and

to select the adapter for other MIG Gun styles, ie.

Miller

®

, Lincoln

®

or Euro.

Figure 2-2: Front Panel Controls and Connections