Section 4: operation, 01 prewelding procedure, Section 4 – Tweco VS212 Wire Feeder User Manual

Page 29: Operation -1, 01 prewelding procedure -1, Transmig vs 212

TRANSMIG VS 212

Manual No. 0-4949

4-1

OPERATION

SECTION 4:

OPERATION

4.01 Prewelding Procedure

Follow all installation instructions for the welding

power source, the welding gun, and the VS 212 CC/

CV wire feeder before attempting to weld.

1. Make sure all necessary connections have been

made (refer to Connections in the Installation

chapter of this manual).

2. Turn ON the power source and the wire feeder.

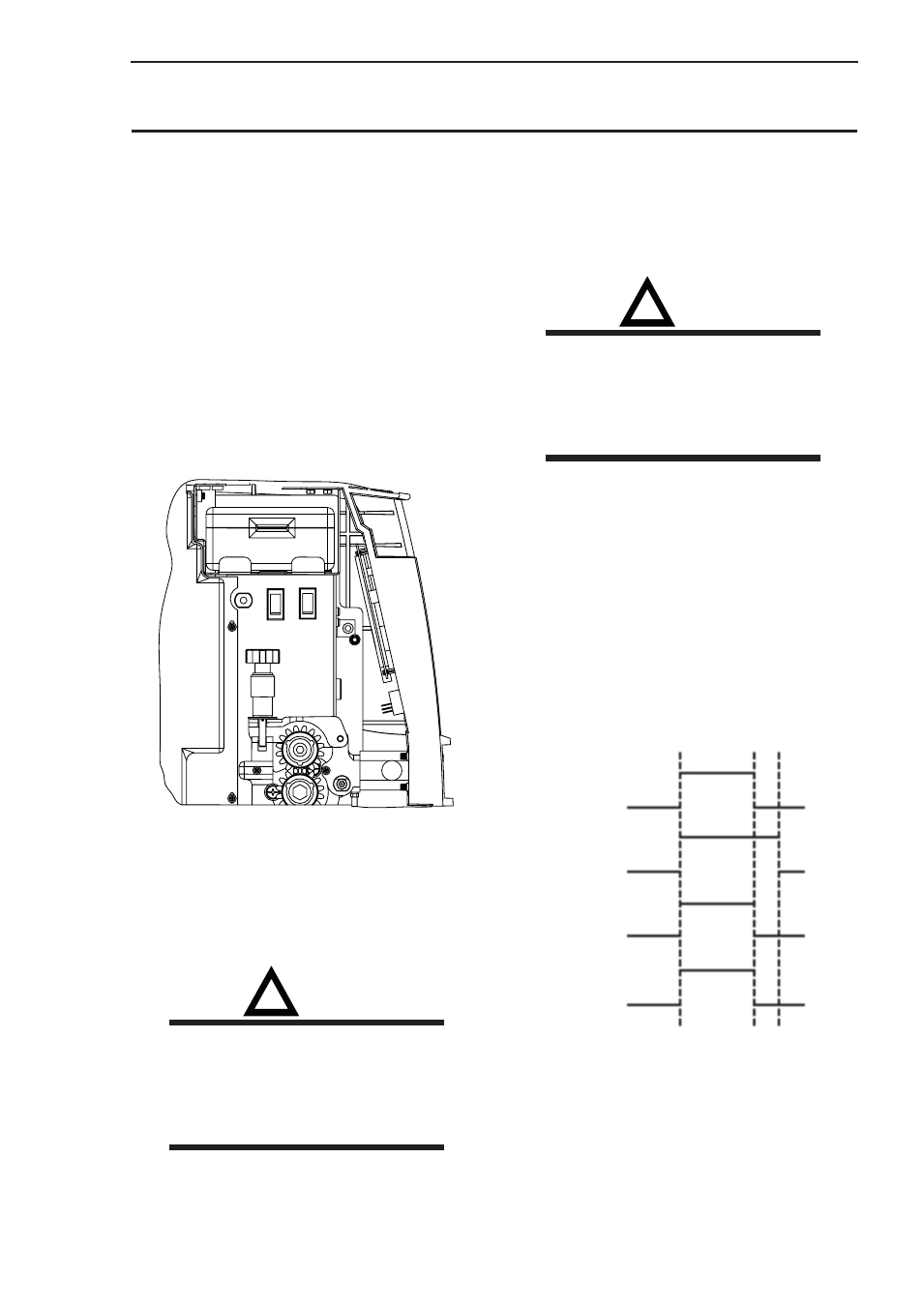

3. Set the CC/CV mode switch on the wire feeder to

the proper position (refer to paragraph 12, CC/CV

Mode Switch on page 2-9 and figure 4-1).

High

Low

CC

CV

Art # A-07254

Figure 4-1: CC/CV Switch Location

4. If shielding gas will be used, depress the purge

switch (if equipped) or gun switch and adjust the

flow of gas.

!

WARNING

If the gun switch is depressed, the wire

feeder will feed electrically hot welding

wire. If this hot welding wire touches the

work piece, a welding arc will be

established.

5. Depress the inch switch (if equipped) or gun

switch and adjust the wire feed speed to the

desired value by means of the wire feed speed

control. The wire feed speed control can be

adjusted during setup or while welding.

!

WARNING

If the gun switch is depressed, the wire

feeder will feed electrically hot welding

wire. If this hot welding wire touches the

work piece, a welding arc will be

established.

6. Adjust the voltage control (on a CV machine) or

current control (on a CC machine) to the desired

value. The voltage or current control can be

adjusted during setup or while welding.

7. If using a CV power source, the output contactor

on the power source will have to be energized. In

most cases, this will require a jumper to be added

to the power source or a switch on the power

source to be turned on. Read the power source

owner’s manual for proper connections or settings

required.

Gun Switch

Gas Valve

Wire Feed

Power Source

ON

ON

ON

ON

OFF

OFF

OFF

OFF

Art # A-05126

Figure 4-2: Functional Timing Diagram