04 general information, 05 safety, 06 protective filter lenses – Tweco 281 Thermal Arc Fabricator User Manual

Page 18: Fabricator 281

FABRICATOR 281

2-2

April 10, 2006

2.04 General Information

The Fabricator 281 is a 208-230 Volt MIG machine with a

best in class performance of 300 Amp maximum output

@ 40% duty cycle, 24 voltage steps, digital meter and

dual cylinder racks. The completely separate wirefeeder

system has 26ft (8m) interconnection cables, spool gun

operation on demand and spot/stitch timers. The

wirefeeder, with fitted wheels, conveniently fits on a pivot

mount on top of the power source or can be lifted off the

pivot and carried up on top of equipment or machinery

up to 26 feet away. Additionally, the spool gun connects

to the wirefeeder allowing even further distance. The

Fabricator 281 is an extremely versatile all round

performer in its class.

The Fabricator 281 gives excellent performance on mild

steel, stainless steel, aluminum, silicon bronze and some

hard facing wires with Argon based shielding gases. The

Power Supply also gives excellent results on mild steel

using Carbon Dioxide shielding gas.

The Fabricator 281 is supplied as a complete package

ready to weld (apart from gas cylinder and electrode wire).

The following instructions detail how to correctly set up

the welder and give guidelines on gaining the best

production efficiency from the Power Supply. Please read

these instructions thoroughly before using your Fabricator

welder.

2.05 Safety

The following basic safety rules should always be fol-

lowed:

• Ensure the machine is correctly installed, if neces-

sary, by a qualified electrician.

• Ensure the Power Supply is grounded correctly

(electrically) in accordance with local regulations.

• Excessive heat in the welding cables may cause fire.

Never weld with poor electrical connections, dam-

aged welding cables or exceed the welding cable

current rating as this will produce excessive heat

and may cause a fire.

• Always wear the correct protective clothing for pro-

tection from sparks, molten particles and arc rays.

• When welding in confined spaces, always ensure

adequate ventilation and constant observation of the

operator.

• Keep combustible materials away from the welding

area. Have a suitable fire extinguisher handy.

• Never watch the welding arc with naked eyes. Al-

ways use and wear a welding mask fitted with the

correct filter lens.

• Do not stand on damp ground when welding.

For more complete safety advice please read section 1.

2.06 Protective Filter Lenses

Protective filter lenses are provided to reduce the intensity

of radiation entering the eye thus filtering out harmful

infrared, ultraviolet radiation and a percentage of the

visible light. Such filter lenses are incorporated within face

shields. To prevent damage to the filter lenses from molten

or hard particles an additional hard clear glass or special

plastic external cover lens should be used. This cover

lens should always be kept in place and replaced before

the damage impairs your vision while welding.

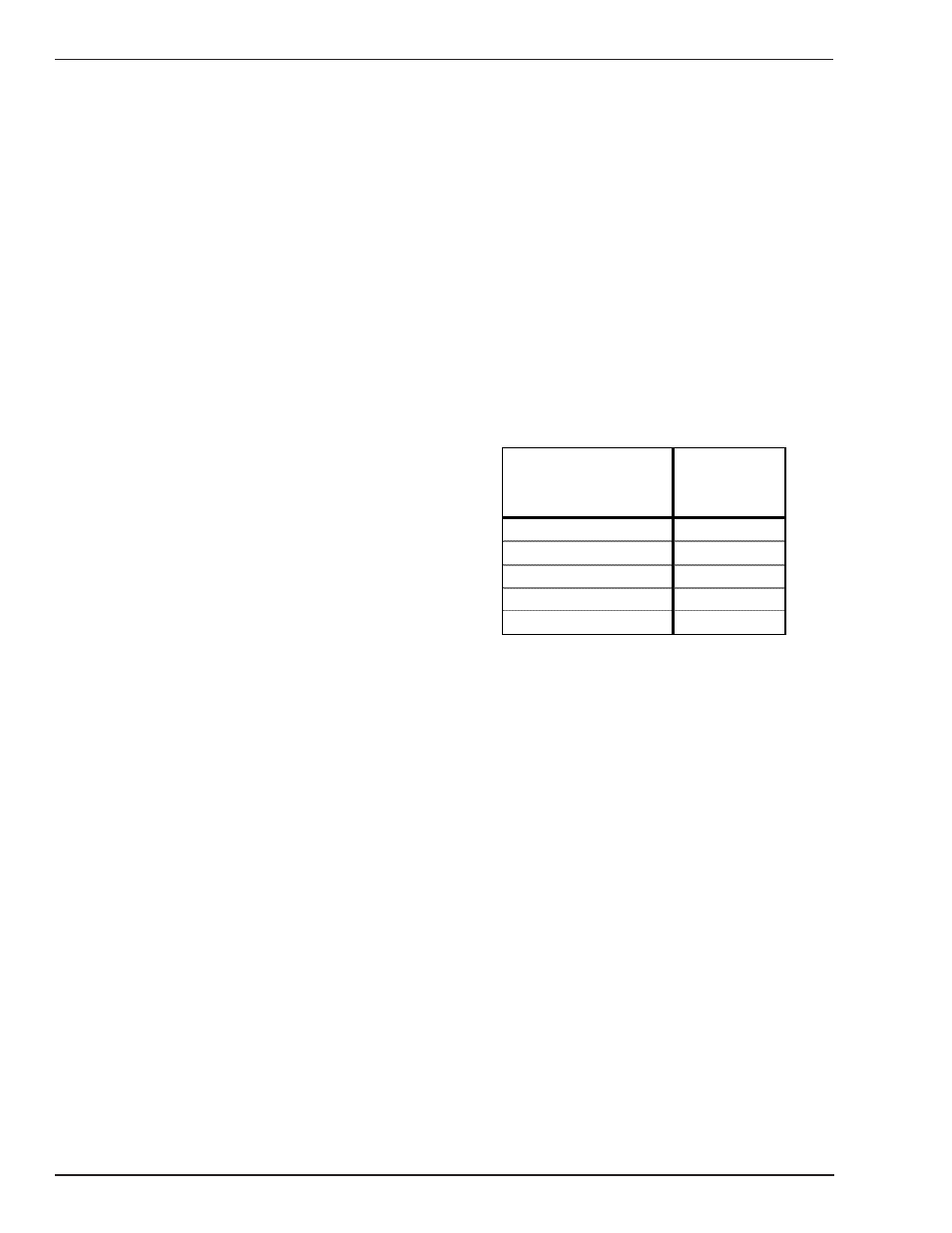

Approximate range of

welding current

Filter lens

required for

MIG

Up to 150

Shade 10

150-250

Shade 11

250-300

Shade 12

300-350

Shade 13

Over 350

Shade 14

Table 2-1: Filter lens size versus welding current

It is recommended to use a welding helmet, conforming

to the local relevant Standards when electric arc welding.

Use a welding helmet in serviceable condition with the

correct filter lens. Refer to Table 2-1 above and AWS table

in Section 1.