05 installing a new wire conduit, 05 installing a new wire conduit -10, Fabricator 251 – Tweco 251 Thermal Arc Fabricator User Manual

Page 48

FABRICATOR 251

OPERATION

4-10

Manual No. 0-4847

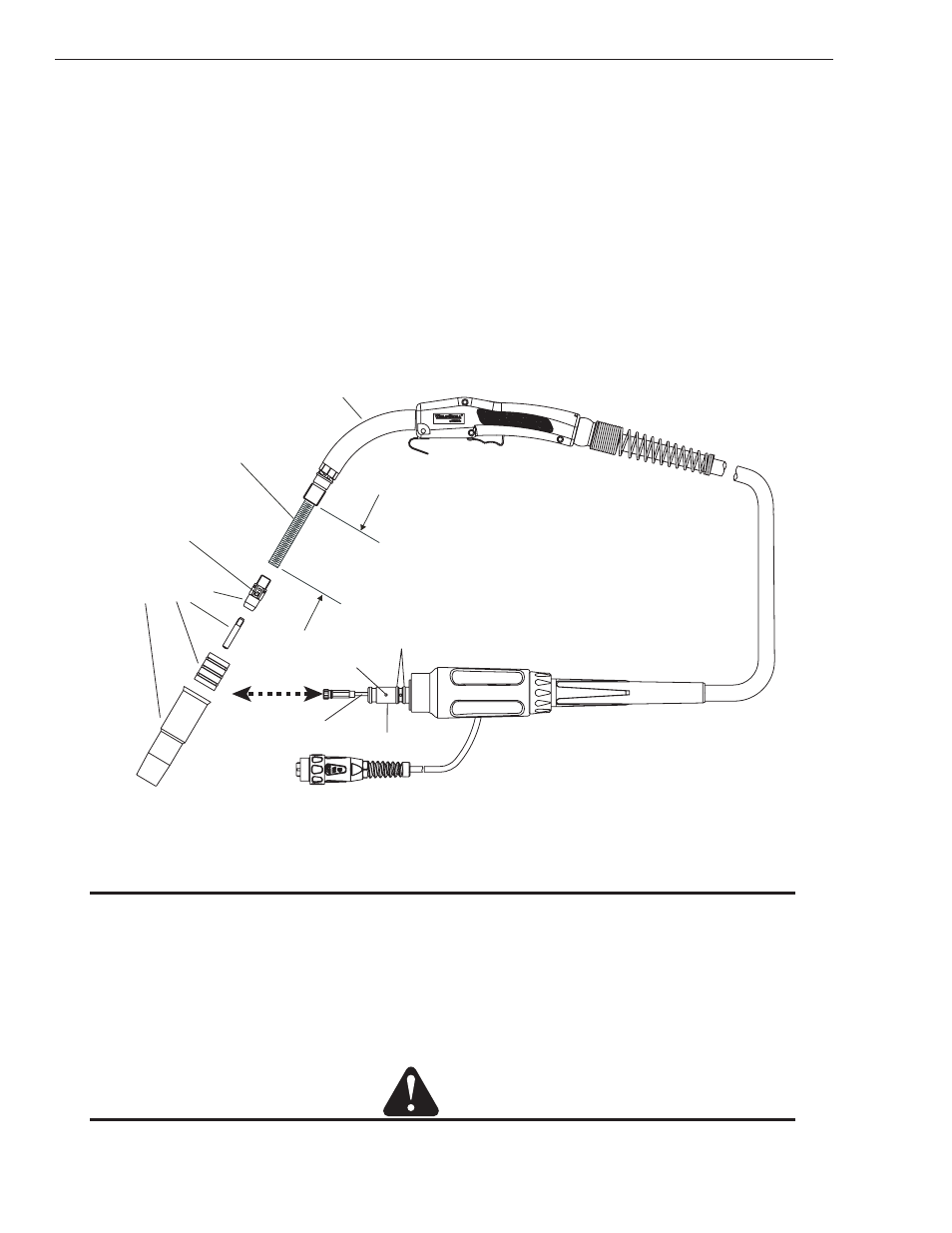

4.05 Installing A New Wire Conduit

1. Be sure the MIG gun cable is arranged in a straight line, free from twists, when installing or removing a wire

conduit. Remove the old conduit by first removing the MIG gun nozzle, contact tip, insulator and gas diffuser.

Then loosen Allen screws in the conductor tube and connector plug and pull the old wire conduit out of the

cable assembly from the connector plug end.

2. To install a new conduit, first inspect the o-ring gas seal on the conduit for cuts or damage. Start from the

connector plug end of the assembly and begin pushing the conduit through the connector plug, cable assem-

bly and into the gun. If the conduit should lodge along the way, gently whip or work the cable assembly to aid

forward movement.

When the conduit stop meets the end of the connector plug and the new raw end extends through the end of

the conductor tube on the welding gun, tighten the Allen screw in the connector plug onto the conduit to

prevent its backward movement.

CONDUCTOR TUBE

CONDUIT LINER

CONDUIT LINER

1 1/16"

(27mm)

Art # A-08236

REMOVE

CONSUMABLES

ALLEN SCREW

O-RINGS

ALLEN SCREW

CONNECTOR PLUG

Figure 4-14: Conduit Trim Length

NOTE

When the conduit is fully inserted into the cable assembly and the conduit stop is firmly against the

Connector Plug, the “raw end” of the conduit will protrude out of the open end of the gun conductor tube.

Trim the conduit as shown in Figure 4-14. The trimmed end which seats in the Gas Diffuser must be filed

and reamed smooth on the inside and outside radii so wire feed will not be obstructed.

3. Replace Gas Diffuser, Contact Tip, Insulator and Nozzle.

4. Tighten the Allen screw in the conductor tube.

CAUTION

Do not over tighten the conductor tube screw as this action will result in the distortion of the conduit and

will lead to wire feedability problems.